Low-temperature-resistant H-shaped steel and production process thereof

A production process, the technology of H-shaped steel, applied in the field of low-temperature resistant H-shaped steel and its production technology, can solve the problems of poor low-temperature impact resistance, low-temperature toughness, and low toughness of H-shaped steel, so as to achieve good low-temperature impact resistance and improve quality , the effect of low ductile-brittle transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

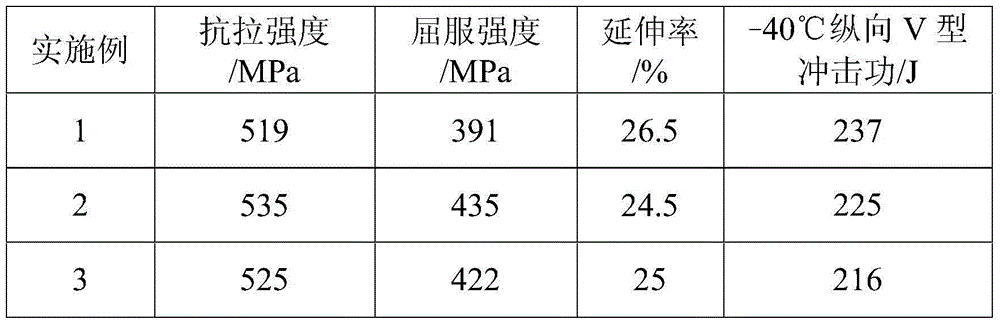

Embodiment 1

[0014] Example 1, the low temperature resistant H-shaped steel has the following chemical components in mass percentage: carbon: 0.10%, silicon: 0.23%, manganese: 1.41%, phosphorus: 0.006%, sulfur: 0.003%, vanadium: 0.036%, Als : 0.021%, the balance is iron and impurity elements.

[0015] The steel undergoes molten iron pretreatment→converter smelting→argon blowing in ladle→LF refining→full-protection casting of shaped blanks→H-shaped steel wire rolling, and finally the rolled piece is cooled. Among them, H-shaped steel wire rolling includes rough rolling and finishing rolling. The operation that the present invention does not mention all can adopt prior art.

[0016] Among them, the rolling process parameters are: heating temperature 1230°C, initial rolling start temperature 1100°C, finish rolling start temperature 936°C, finish rolling finish temperature 885°C;

[0017] The cooling process parameters are: the rolled piece is cooled at a cooling rate of 109 °C / s to a phase ...

Embodiment 2

[0019] Example 2, the low temperature resistant H-shaped steel has the following chemical components in mass percentage: carbon: 0.11%, silicon: 0.25%, manganese: 1.36%, phosphorus: 0.005%, sulfur: 0.007%, vanadium: 0.038%, Als : 0.019%, the balance is iron and impurity elements.

[0020] The steel undergoes molten iron pretreatment→converter smelting→argon blowing in ladle→LF refining→full-protection casting of shaped blanks→H-shaped steel wire rolling, and finally the rolled piece is cooled. Among them, H-shaped steel wire rolling includes rough rolling and finishing rolling. The operation that the present invention does not mention all can adopt prior art.

[0021] Among them, the rolling process parameters are: heating temperature 1235°C, initial rolling start temperature 1130°C, finish rolling start temperature 941°C, finish rolling finish temperature 890°C;

[0022] The cooling process parameters are: the rolled piece is cooled at a cooling rate of 105 °C / s to a phase ...

Embodiment 3

[0024] Example 3, the low temperature resistant H-shaped steel has the following chemical components in mass percentage: carbon: 0.10%, silicon: 0.26%, manganese: 1.39%, phosphorus: 0.007%, sulfur: 0.004%, vanadium: 0.034%, Als : 0.028%, the balance is iron and impurity elements.

[0025] The steel undergoes molten iron pretreatment→converter smelting→argon blowing in ladle→LF refining→full-protection casting of shaped blanks→H-shaped steel wire rolling, and finally the rolled piece is cooled. Among them, H-shaped steel wire rolling includes rough rolling and finishing rolling. The operation that the present invention does not mention all can adopt prior art.

[0026] Among them, the rolling process parameters are: heating temperature 1232°C, initial rolling start temperature 1115°C, finish rolling start temperature 945°C, finish rolling finish temperature 893°C;

[0027] The cooling process parameters are: the rolled piece is cooled at a cooling rate of 103 °C / s to a phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com