Tungsten-zirconium carbide-rhenium alloy with high-temperature stability and preparation method thereof

A zirconium carbide and rhenium alloy technology, which is applied in the field of tungsten-zirconium carbide-rhenium alloy and its preparation, can solve the problems of no obvious increase in recrystallization temperature and low elongation, and achieve high recrystallization temperature and low ductile-brittle transition temperature , the effect of high temperature strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

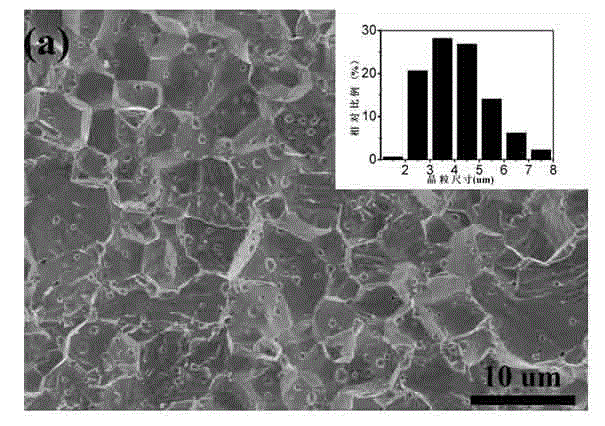

Embodiment 1

[0025] The concrete steps of preparation are:

[0026] Step 1. Put metal tungsten powder, zirconium carbide powder and rhenium powder in a protective atmosphere (or vacuum or Alcohol) mixed evenly; Among them, the particle size of metal tungsten powder is 0.6μm, the particle size of zirconium carbide powder is 10-50nm, the particle size of rhenium powder is 1-2um, and the protective atmosphere is hydrogen atmosphere (or The vacuum degree of vacuum is ≤100Pa), and the mixed powder is obtained.

[0027] Step 2, first press the mixed powder under a pressure of 200MPa to form a green body, then place the green body in a hydrogen atmosphere (or a vacuum with a vacuum degree of ≤100Pa), and sinter and shape it at 1500°C;

[0028] Alternatively, place the mixed powder in a hydrogen atmosphere (or a vacuum with a vacuum degree of ≤100Pa), and sinter it by hot isostatic pressing at a pressure of 100MPa and a temperature of 1500°C;

[0029] Alternatively, place the mixed powder in a h...

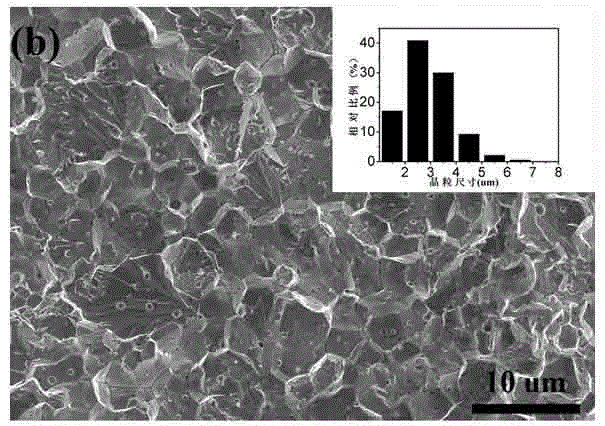

Embodiment 2

[0033] The concrete steps of preparation are:

[0034] Step 1. Put metal tungsten powder, zirconium carbide powder and rhenium powder in a protective atmosphere (or vacuum or Alcohol) mixed evenly; Among them, the particle size of metal tungsten powder is 0.6μm, the particle size of zirconium carbide powder is 10-50nm, the particle size of rhenium powder is 1-2um, and the protective atmosphere is hydrogen atmosphere (or The vacuum degree of vacuum is ≤100Pa), and the mixed powder is obtained.

[0035] Step 2, first press the mixed powder under a pressure of 300MPa to form a green body, then place the green body in a hydrogen atmosphere (or a vacuum with a vacuum degree of ≤100Pa), and sinter and shape it at 1675°C;

[0036] Alternatively, place the mixed powder in a hydrogen atmosphere (or a vacuum with a vacuum degree of ≤100Pa), and sinter it by hot isostatic pressing at a pressure of 130MPa and a temperature of 1625°C;

[0037] Alternatively, place the mixed powder in a h...

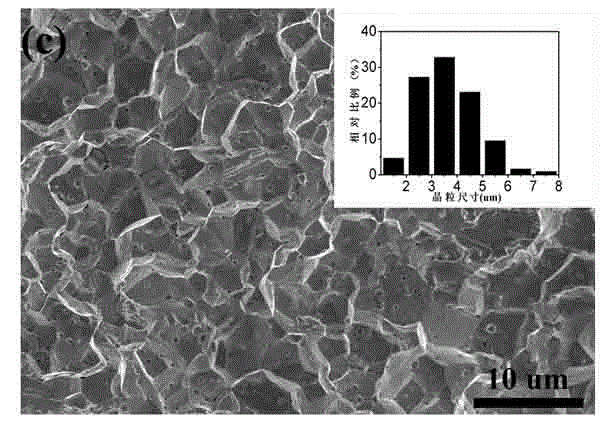

Embodiment 3

[0041]The concrete steps of preparation are:

[0042] Step 1. Put metal tungsten powder, zirconium carbide powder and rhenium powder in a protective atmosphere (or vacuum or Alcohol) mixed evenly; Among them, the particle size of metal tungsten powder is 0.6μm, the particle size of zirconium carbide powder is 10-50nm, the particle size of rhenium powder is 1-2um, and the protective atmosphere is hydrogen (or vacuum The vacuum degree is ≤100Pa), and the mixed powder is obtained.

[0043] Step 2, first press the mixed powder under a pressure of 400MPa to form a green body, then place the green body in a hydrogen atmosphere (or a vacuum with a vacuum degree of ≤100Pa), and sinter at 1850°C;

[0044] Alternatively, place the mixed powder in a hydrogen atmosphere (or a vacuum with a vacuum degree of ≤100Pa), and sinter it by hot isostatic pressing at a pressure of 150MPa and a temperature of 1750°C;

[0045] Alternatively, place the mixed powder in a hydrogen atmosphere (or a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com