Structural adhesive with excellent low-temperature impact peel strength and preparation method thereof

A technology of peel strength and low temperature impact, applied in the field of structural adhesives, can solve the problems of inability to meet the performance requirements of automobiles, poor impact resistance, poor impact resistance of body structural adhesives, etc., to achieve good high and low temperature shear strength, excellent low temperature Impact resistance, the effect of meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

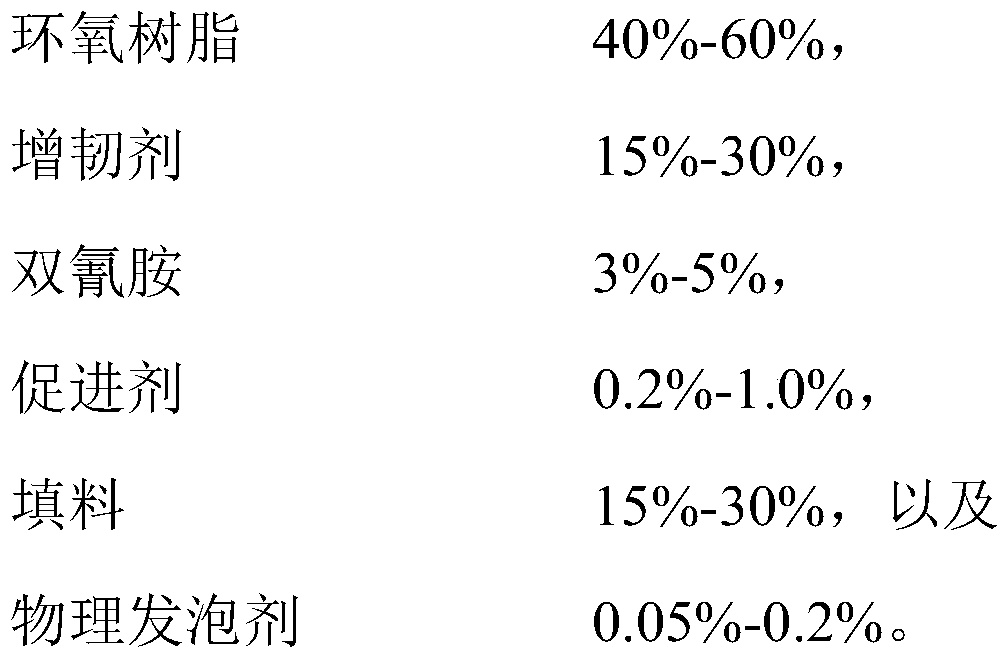

[0040] This embodiment provides a structural adhesive prepared from the raw materials shown in Table 1 below:

[0041] Table 1 Structural adhesive composition table of Example 1

[0042]

[0043]

[0044] The preparation method of the present embodiment structural adhesive comprises the following steps:

[0045] S1, weigh each raw material according to Table 1.

[0046] S2. Stir and mix the epoxy resin and the toughening agent at 55±5°C for 4 hours until completely dissolved to obtain a liquid mixture.

[0047] S3, add the liquid mixture, dicyandiamide and accelerator into the dynamic mixer respectively, and stir for 30min-40min under the conditions of 35±5°C, 15Hz revolution, and 30Hz rotation until uniformly dispersed to obtain an intermediate mixture.

[0048] S4, then add filler and physical blowing agent to the intermediate mixture, continue to stir for 5min-10min at 35±5℃, revolution 15Hz, rotation 10Hz until the dispersion is uniform, vacuum defoaming, the proce...

Embodiment 2

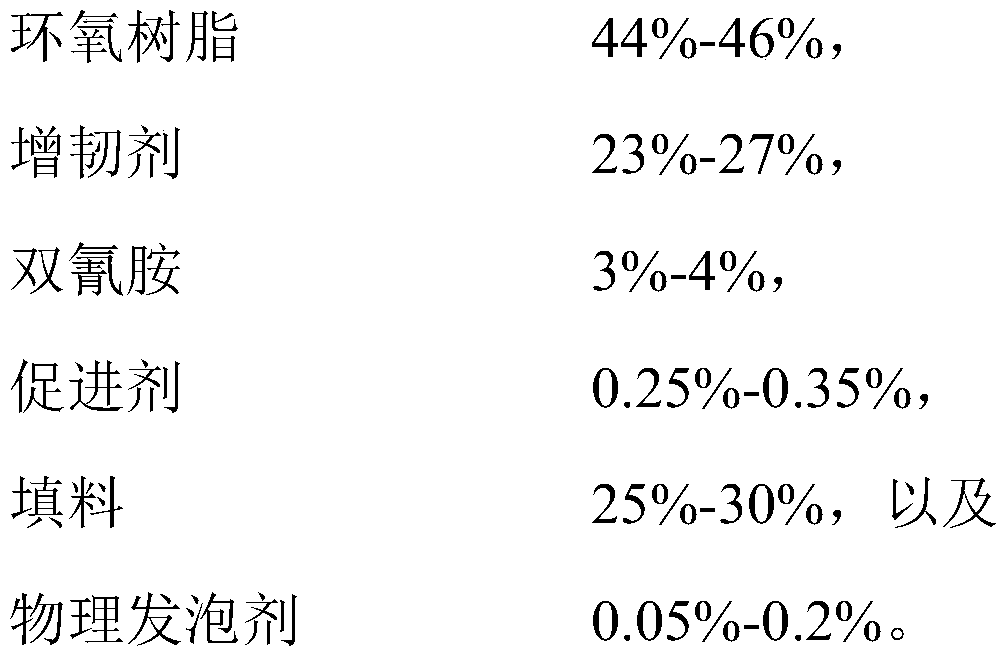

[0050] This embodiment provides a structural adhesive prepared from the raw materials shown in Table 2 below:

[0051] Table 2 Structural adhesive composition table of Example 2

[0052]

[0053]

[0054] The preparation method of the structural adhesive of this example is the same as that of Example 1.

Embodiment 3

[0056] This embodiment provides a structural adhesive prepared from the raw materials shown in Table 3 below:

[0057] Table 3 The structural adhesive composition table of Example 3

[0058]

[0059]

[0060] The preparation method of the structural adhesive of this example is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com