Flame-retardant PVC cable tube and preparation method thereof

A cable tube and flame retardant masterbatch technology, which is applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problems of high brittleness, easy corrosion of PVC pipes, poor impact resistance of PVC pipes, etc. The effect of improving low temperature impact resistance, good insulation and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

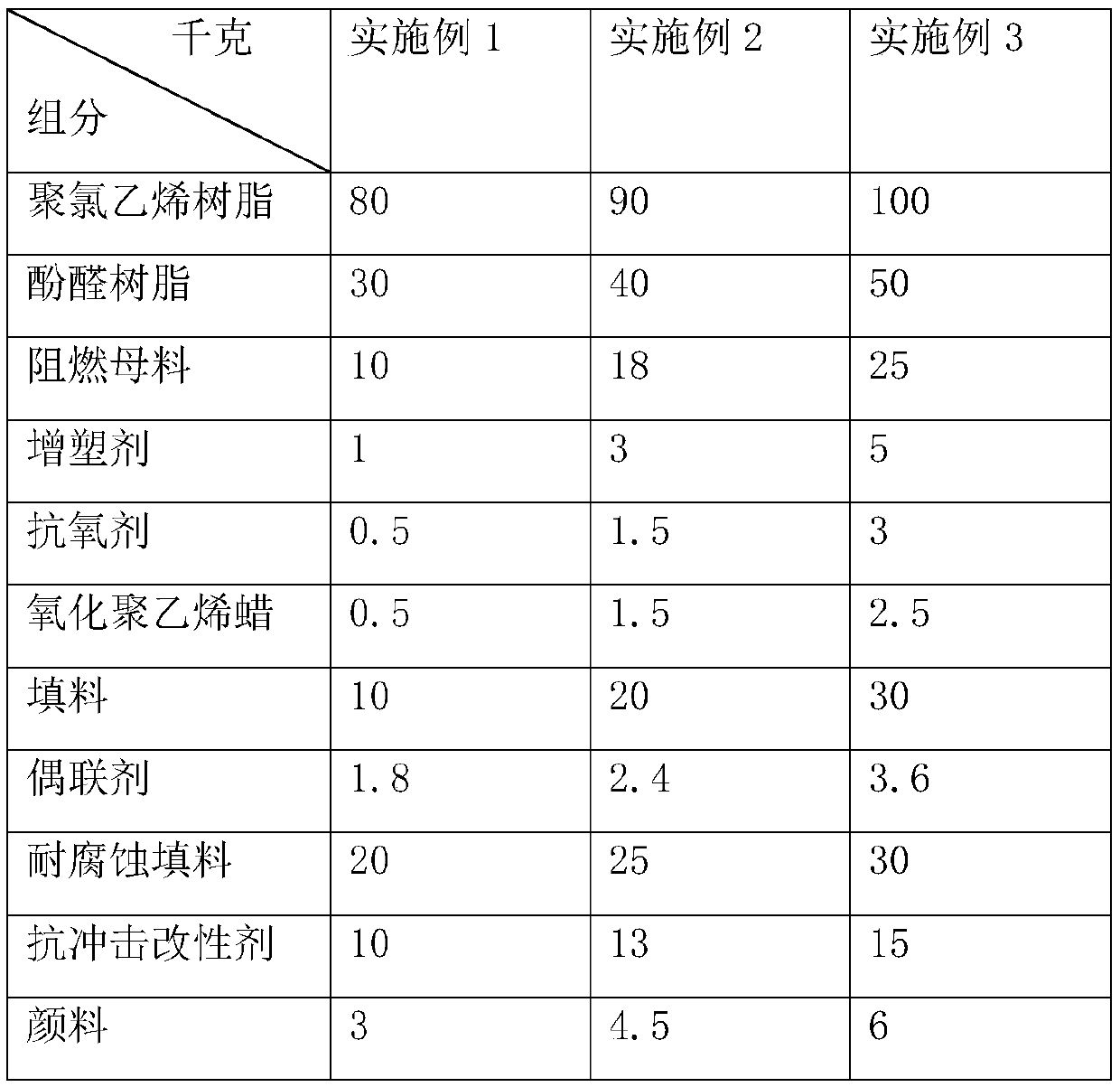

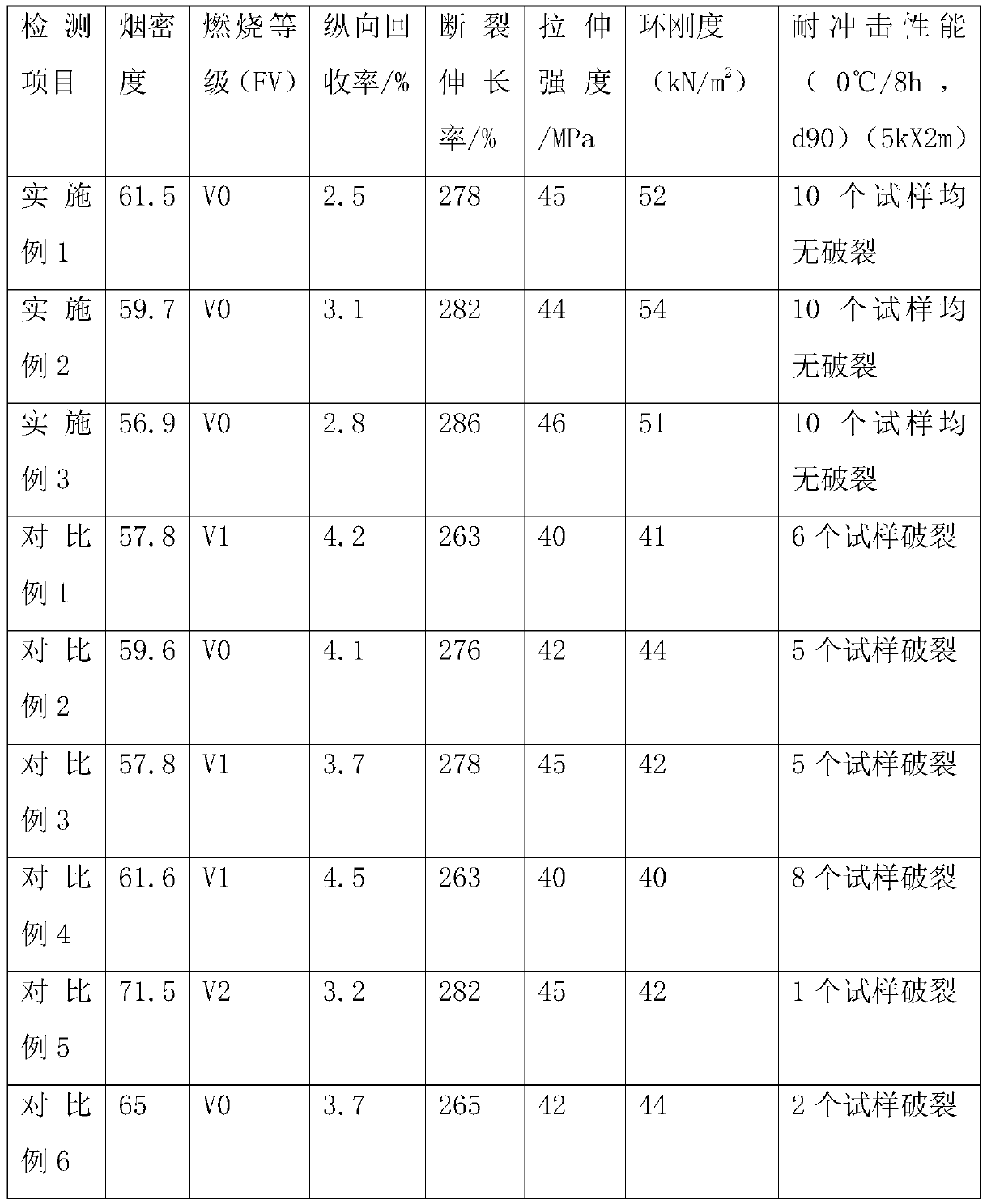

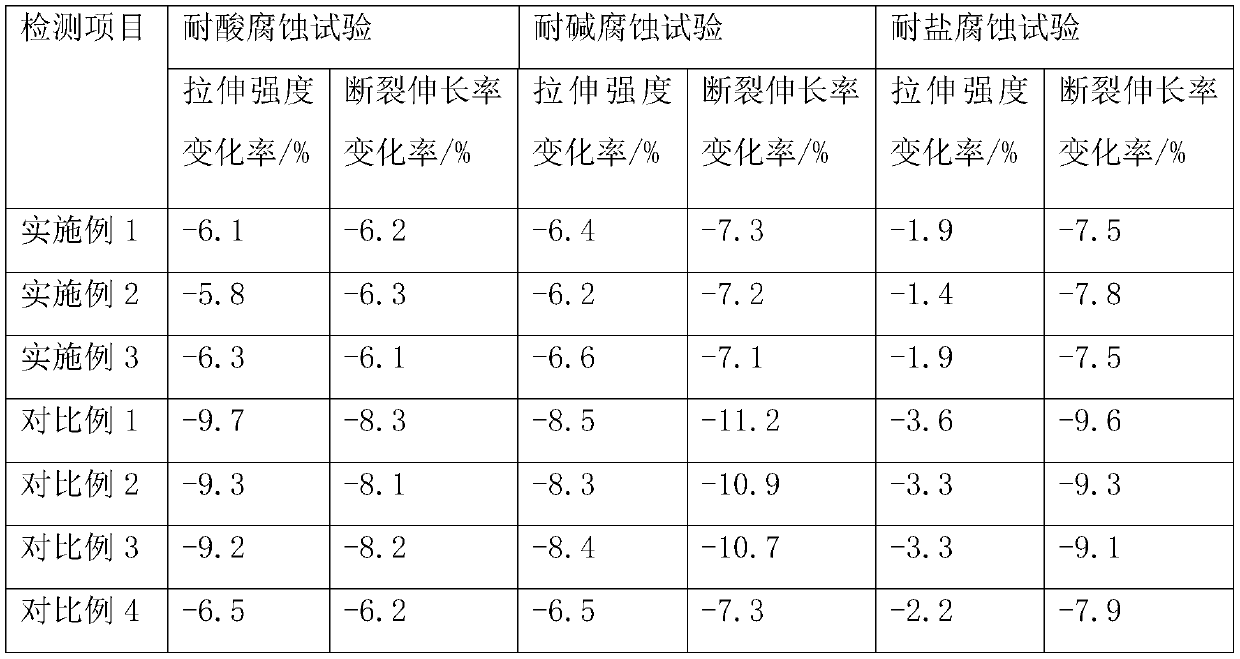

Examples

preparation example 1-3

[0034] The aramid fibers in Preparation Examples 1-3 are selected from the aramid fibers sold by Dongguan Kaitlun New Material Co., Ltd. with the product number T-78000.

preparation example 1

[0035] Preparation example 1: (1) add distilled water to the mixture of 0.6g tris and 0.7g hydrochloric acid, make the pH be 8.5;

[0036] (2) Immerse 3g of aramid fiber in 5mL of ethanol solution with a concentration of 20mg / mL for 20min, wash with distilled water prepared in step (1) and dry, place the dried aramid fiber in 5mL of ethanol solution with a concentration of 0.5mg / mL Soak in the dopamine alkaline aqueous solution for 3 minutes, take it out and react for 2 minutes in a hot air stream at 60°C.

preparation example 2

[0037] Preparation example 2: (1) add distilled water to the mixture of 0.65g Tris and 0.75g hydrochloric acid, make the pH be 8.5;

[0038] (2) Immerse 4g of aramid fiber in 8mL of ethanol solution with a concentration of 20mg / mL for 25min, wash and dry with the distilled water prepared in step (1), and place the dried aramid fiber in 6mL of ethanol solution with a concentration of 0.5mg / mL Soak in dopamine alkaline aqueous solution for 4 minutes, take it out and react for 2.5 minutes in a hot air stream at 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com