Thermal insulation thermoplastic composite material for roadbed

A technology of composite materials and thermal insulation materials, applied in the field of thermal insulation thermoplastic composite materials for roadbeds, can solve the problems of poor impact resistance, non-corrosion resistance, high brittleness, etc., and achieve the effect of improving the application field, good thermal insulation performance, and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

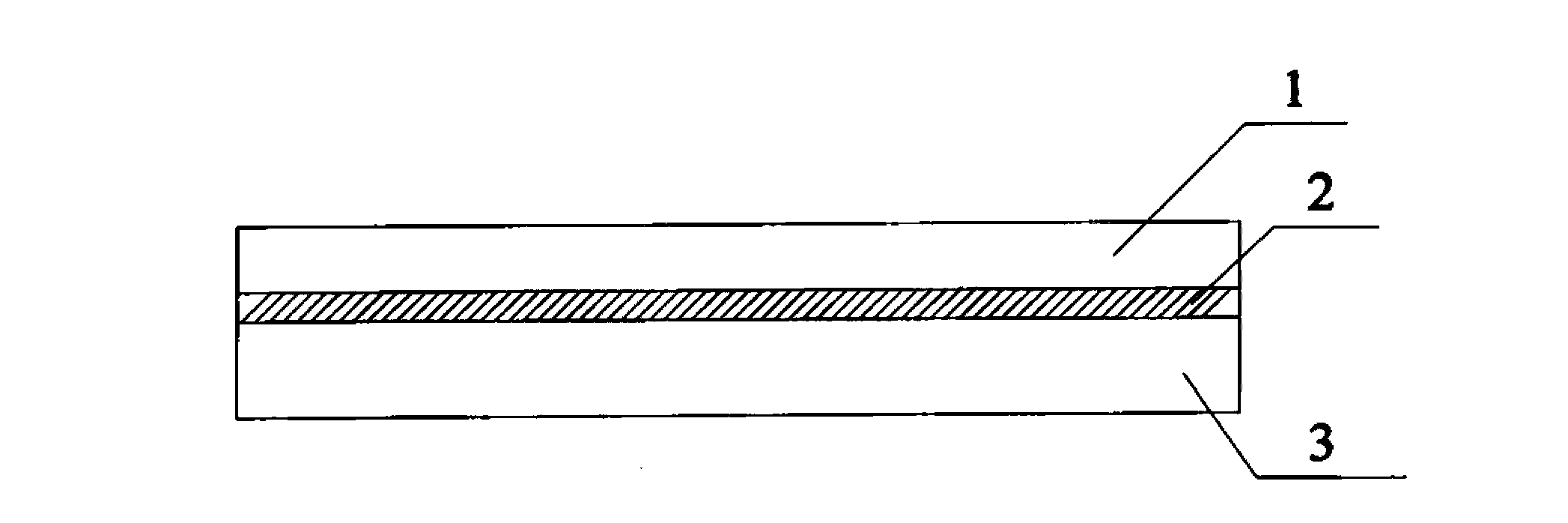

[0041] A kind of thermal insulation thermoplastic composite material for roadbed, its structure is as follows figure 1 As shown, the heat-insulating thermoplastic composite material for the subgrade consists of three layers, the base layer 3 is the heat-insulation layer, the middle layer 2 is the high-strength adhesive layer, and the upper layer 1 is the thermoplastic composite material. The upper layer 1 thermoplastic composite acts as a skin layer to provide the strength of the entire composite. Rigidity and impact performance, the middle layer 2 adhesive layer serves as a transition layer to provide connection, and the base layer 3 mainly provides thermal insulation and antifreeze performance.

[0042] The above three layers of materials are bonded and pressed together by a high-strength adhesive layer. Among them, the thermoplastic composite material is carbon fiber reinforced nylon 6 copolymer (among them, the content of nylon 6 copolymer is 40%, the content of carbon fi...

Embodiment 2

[0048] A thermal insulation thermoplastic composite material for roadbed, the composite material has a three-layer structure, the base layer 3 is thermal insulation material, the middle layer 2 is a high-strength adhesive layer, the upper layer 1 is a thermoplastic composite material, and the above three layers are bonded by high-strength adhesive It is formed by bonding and pressing composite layers. Among them, the thermoplastic composite material is glass fiber-reinforced polypropylene copolymer, the high-strength bonding layer is an EVA film layer, and the insulation layer is a benzene board insulation layer.

[0049] The preparation method of thermal insulation thermoplastic composite material comprises the following steps:

[0050] (1) Pass the glass fiber reinforced polypropylene composite material with a fiber content of 55% and a resin content of 45% through a roller, the temperature of the roller is 150°C to heat and melt the composite material, and the pressure of t...

Embodiment 3

[0054] A thermal insulation thermoplastic composite material for roadbed, the composite material has a three-layer structure, the base layer is a thermal insulation material, the middle layer is a high-strength bonding layer, and the upper layer is a thermoplastic composite material, and the above three layers are bonded by a high-strength bonding layer Combined and pressed together. The thermoplastic composite material is a blend of carbon fiber reinforced polyethylene and polypropylene, the high-strength bonding layer is a Dow Corning DC7091 silica gel layer, and the insulation layer is a polyurethane insulation layer.

[0055] The preparation method of the above-mentioned thermal insulation thermoplastic composite material comprises the following steps:

[0056] (1) Pass the carbon fiber reinforced polyethylene and polypropylene composite materials with a fiber content of 50% and a resin content of 50% through the No. 1 roll, and the temperature of the No. 1 roll is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com