Annealing preparation process for enhancing product of strength and elongation of twinning-induced plasticity high-manganese steel board

A technology of twinning induced plasticity and preparation process, which is applied in the field of iron and steel material manufacturing, can solve the problems of inability to guarantee the total reduction rate of cold rolling, high annealing temperature, and large load of the rolling mill, and achieve the improvement of heat treatment process and rolling method, Improve the strength and plasticity, eliminate the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

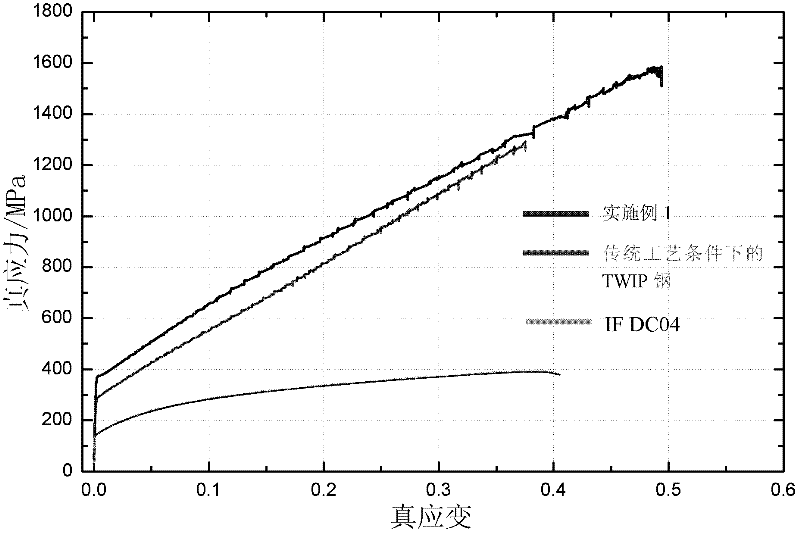

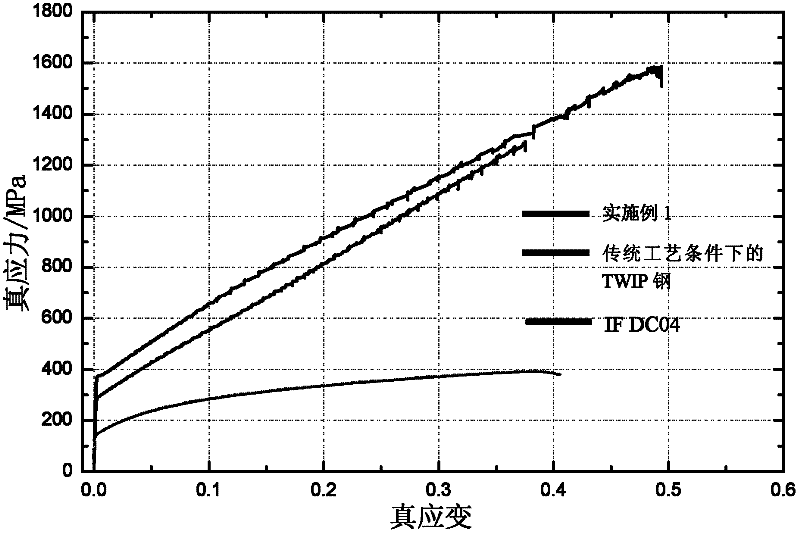

Image

Examples

Embodiment 1

[0025] The preparation steps of embodiment 1:

[0026] (1) Smelt according to the following composition (mass percentage): C: 0.56%, Si: ≤0.012%, Al: ≤0.1%, Mn: 22.5%, P: ≤0.1%, S: ≤0.02% , and the balance is iron or unavoidable impurities. In the designed chemical composition of Example 1, the contents of Al and Si are extremely low.

[0027] (2) Heat the billet to 1150±50°C for one hour, and forge it into a steel billet with a thickness of 80mm.

[0028] (3) Using rolling technology, carry out conventional hot rolling on the steel plate blank, wherein the hot rolling heating temperature is 1200±10°C, and start rolling after holding for 1 hour, and carry out multi-pass hot rolling, the starting rolling temperature is 1100°C, and the final rolling temperature is 1100°C. The rolling temperature was 900° C. to obtain a hot-rolled sheet having a thickness of 4.5 mm. Air-cool to room temperature after final rolling to obtain a hot-rolled sheet in use.

[0029] (4) The hot-ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com