High-strength and high-modulus casting Mg-RE alloy and preparation method thereof

A magnesium rare earth alloy, high modulus technology, applied in the field of metal materials, can solve the problems of low elastic modulus, poor elastic deformation resistance, unsatisfactory, etc., achieve long duration, long refinement effect, and reduce burning loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] On the other hand, the present invention also provides a method for preparing the above-mentioned magnesium alloy, which includes two steps of vacuum melting and heat treatment in sequence.

[0027] As a preferred solution, the vacuum melting step is performed in CO 2 And SF 6 Under the protection of mixed gas (ratio 100:1), it includes the following operations:

[0028] After mixing the ingredients according to the stoichiometric ratio of the elements in the magnesium alloy, preheat the pure Mg, pure Al, pure Zn and the master alloy Mg-Nd at 180~220℃ for more than 2 hours;

[0029] After the preheated pure Mg is melted, pure Zn is added to melt at 670~690℃, the temperature is raised to 720~740, and Mg-Nd master alloy is added for melting. When the melt temperature rises to 720~740℃, pure Zn is added. Al, stir after pure Al is completely melted. After stirring, add pure Li at 700~740℃. After pure Li is completely melted, heat the melt to 780~800℃ for 20~30min and then cool to ...

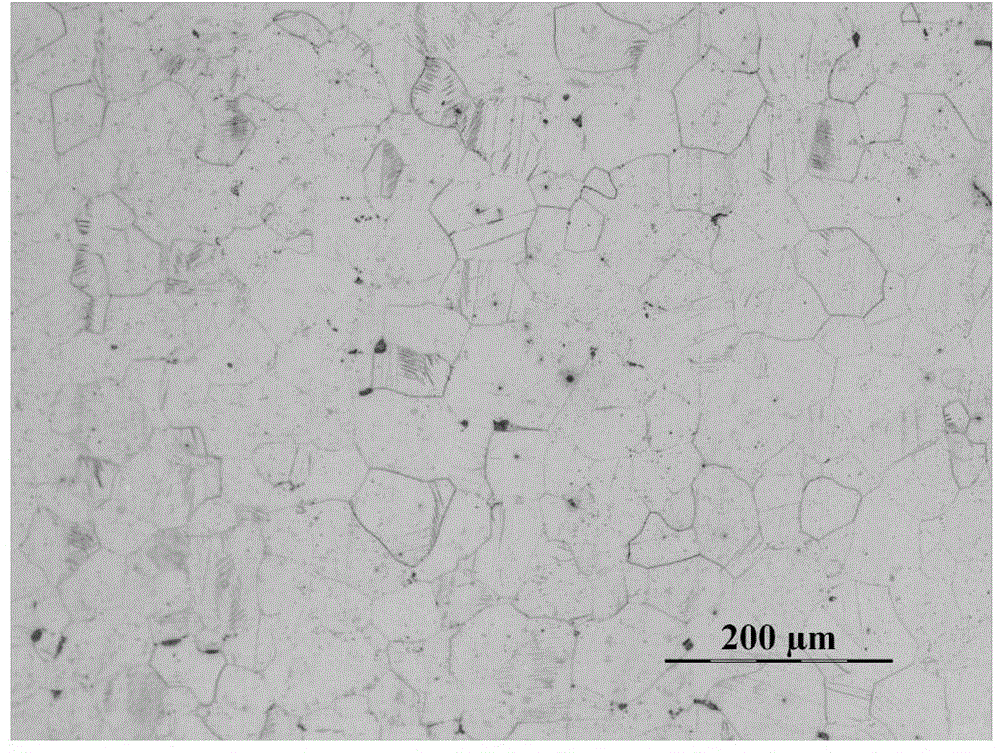

Embodiment 1

[0034] The components and mass percentages of the high-strength and high-mold cast magnesium rare earth alloy in this embodiment are: 4wt.%Nd, 0.6wt.%Zn, 3wt.%Li, 4wt.%Al, impurity elements Si, Fe, Cu and The total amount of Ni is less than 0.02wt.%, and the balance is Mg.

[0035] The preparation method of the magnesium alloy includes two process steps of smelting and subsequent heat treatment.

[0036] Among them, the previous smelting process is in CO 2 And SF 6 Under the protection of mixed gas (ratio 100:1), the steps are as follows:

[0037] (1) Material preparation: according to the element ratio of the magnesium rare earth alloy of this embodiment, weigh pure Mg, pure Zn, pure Al, pure Li and master alloy Mg-Nd, among which the content of Nd in master alloy Mg-Nd Is 25wt%;

[0038] (2) Baking material: Preheat pure Mg, pure Zn, pure Al, master alloy Mg-Nd at 220℃ for more than 2 hours, pure Li does not need to be preheated;

[0039] (3) Molten magnesium: use a crucible resista...

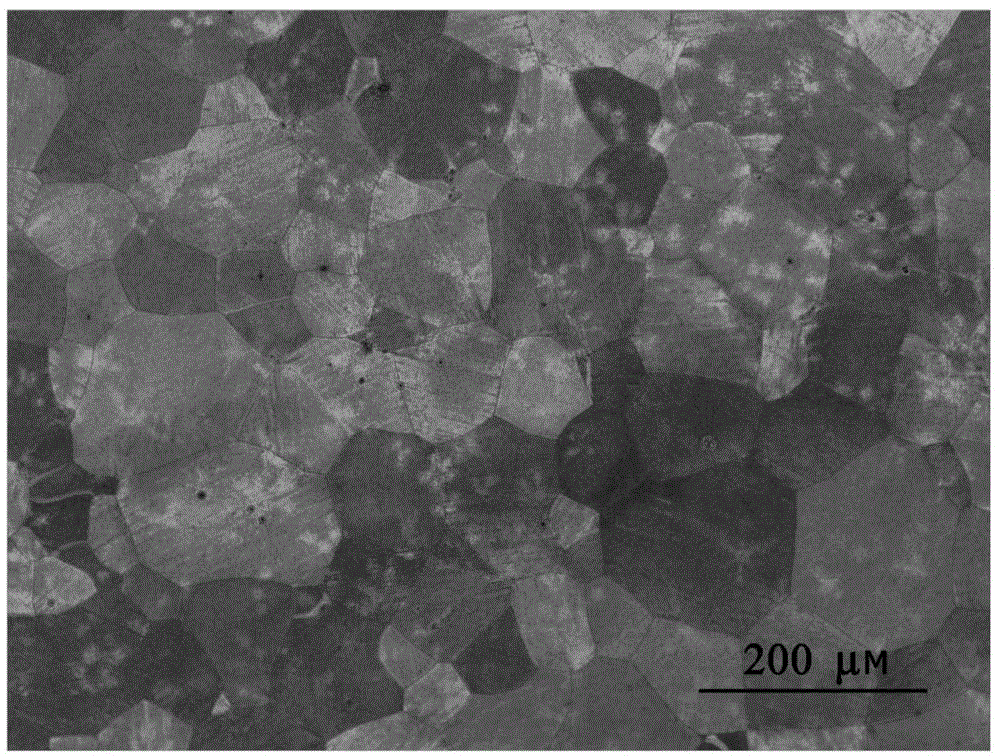

Embodiment 2

[0048] The composition and mass percentage of the high-strength and high-mold casting magnesium rare earth alloy in this embodiment are: 2wt.%Nd, 0.4wt.%Zn, 2wt.%Li, 3wt.%Al, and impurity elements Si, Fe, Cu and The total amount of Ni is less than 0.02wt.%, and the balance is Mg (wt.% refers to the percentage of the total mass of the prepared magnesium alloy, the total mass is Mg, Zn, Al, Li and Mg-Nd master alloy Quality and).

[0049] The preparation method of the magnesium alloy includes two process steps of smelting and subsequent heat treatment.

[0050] Among them, the previous smelting process is in CO 2 And SF 6 Under the protection of mixed gas (ratio 100:1), the steps are as follows:

[0051] (1) Material preparation: according to the element ratio of the magnesium rare earth alloy of this embodiment, weigh pure Mg, pure Zn, pure Al, pure Li and master alloy Mg-Nd, among which the content of Nd in master alloy Mg-Nd Is 25wt%;

[0052] (2) Baking material: Preheat pure Mg, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com