Transparent rare earth ion-doped hexagonal sodium yttrium fluoride oxyfluoride glass-ceramics and preparation method thereof

A technology of rare earth ions and sodium yttrium fluoride, which is applied in the field of rare earth ion doped β-NaYF4 oxyfluoride glass-ceramics and its preparation, can solve problems such as unsatisfactory, glass devitrification, and excessively large nanocrystal crystallization size. Achieve the effect of improving the luminous efficiency of up-conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

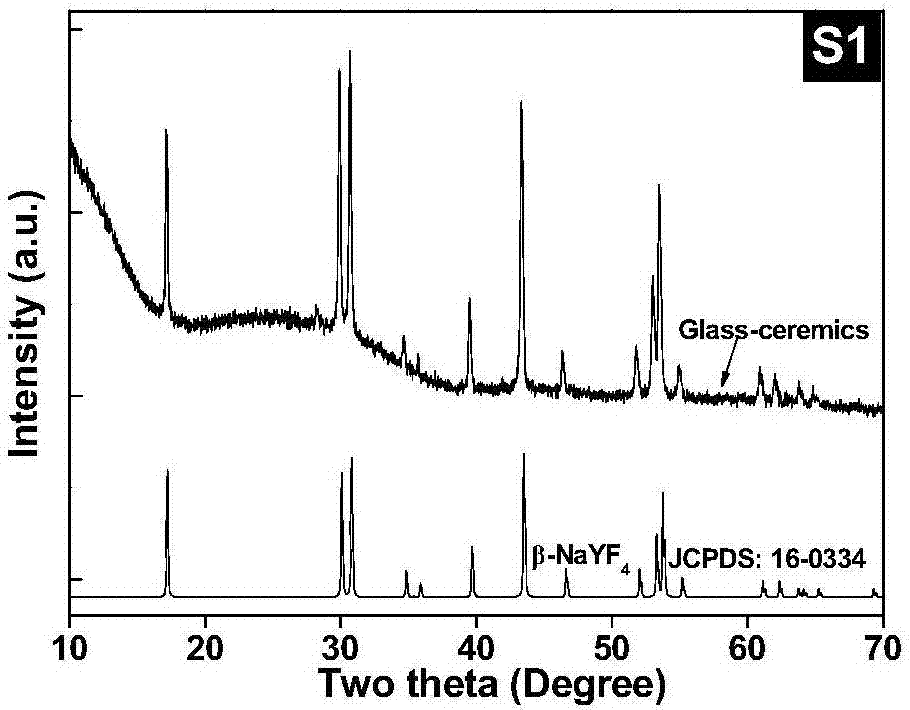

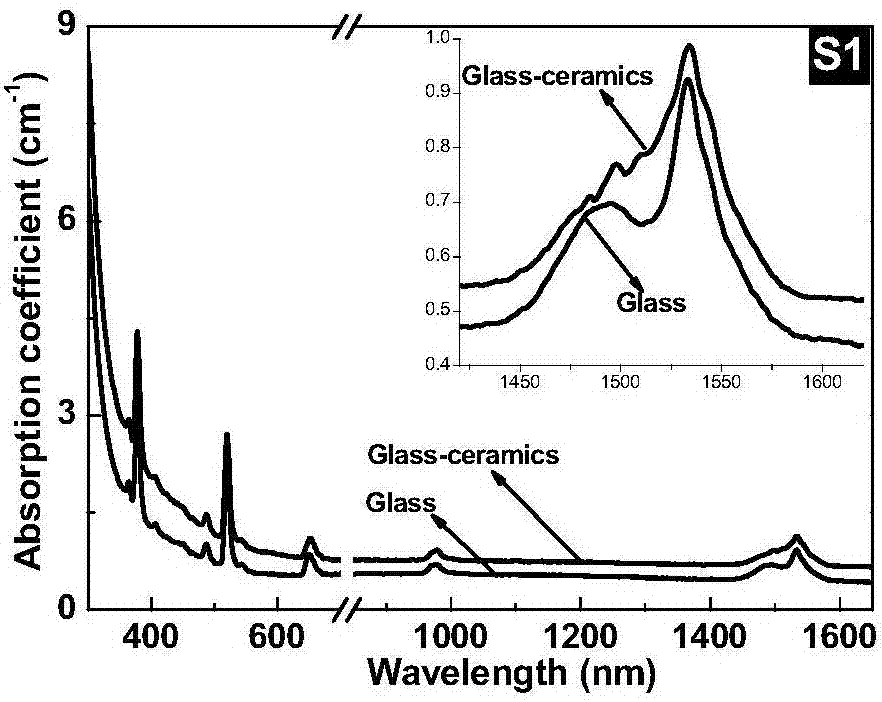

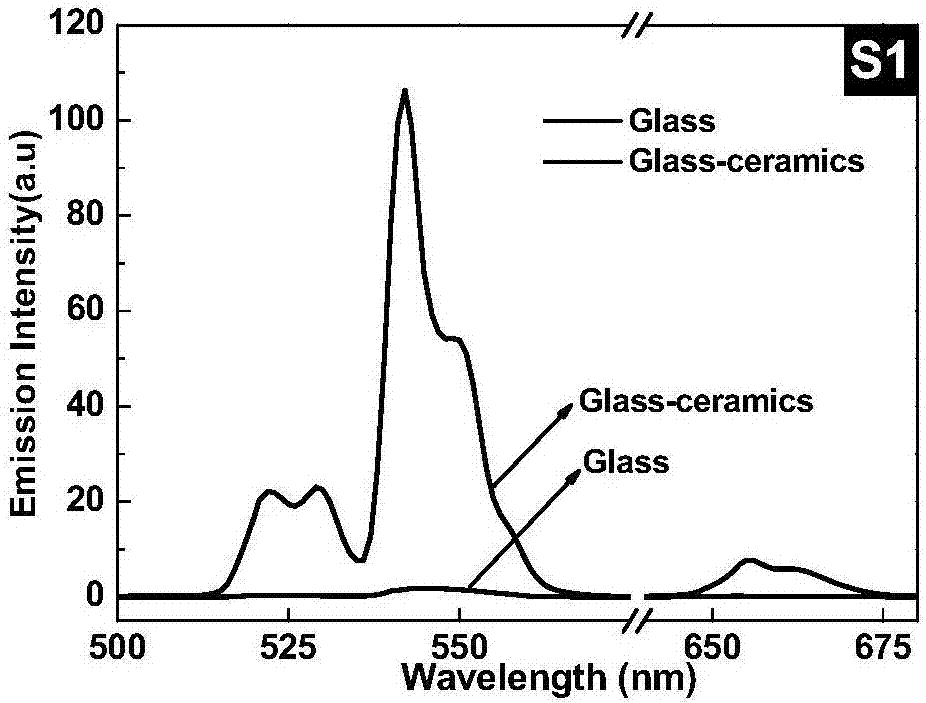

[0025] The glass composition (S1) of the present embodiment is: SiO 2 :60mol%, Al 2 o 3 : 9mol%, Na 2 O: 16mol%, NaF: 7mol%, YF 3 :8mol%, ErF 3 : 0.5mol%, raw material selection of analytically pure SiO 2 、Al 2 o 3 、Na 2 CO 3 , NaF and spectrally pure YF 3 with ErF 3 . Weigh the raw material SiO according to the above mole percentage 2:13.5529g,Al 2 o 3 :3.4498g,Na 2 CO 3 :6.3753g,NaF:1.1050g,YF 3 :4.3880g,ErF 3 : 0.4215g, fully mixed evenly with a ball mill mixer, placed in a dense corundum crucible, melted at 1500°C for 1.5 hours; then poured the resulting glass melt on a metal copper mold for rapid compression molding, and annealed at 350°C 3h to obtain a transparent precursor glass; then heat-treat the precursor glass at 650°C for 2 hours to obtain a transparent rare earth ion doped β-NaYF 4 Oxyfluorine glass-ceramics. figure 1 It is the X-ray diffraction pattern of the glass-ceramic after heat treatment of sample S1, compared with the PDF card, the cr...

Embodiment 2

[0027] The glass composition (S2) of the present embodiment is: SiO 2 :60mol%, Al 2 o 3 :7mol%, Na 2 O: 18mol%, NaF: 7mol%, YF 3 :8mol%, ErF 3 : 0.5mol%, raw material selection of analytically pure SiO 2 、Al 2 o 3 、Na 2 CO 3 , NaF and spectrally pure YF 3 with ErF 3 . Weigh the raw material SiO according to the above mole percentage 2 :13.5529g,Al 2 o 3 :2.6832g,Na 2 CO 3 : 7.1722g, NaF: 1.1050g, YF 3 :4.3880g,ErF 3 : 0.4215g, fully mixed evenly with a ball mill mixer, placed in a dense corundum crucible, melted at 1500°C for 1.5 hours; then poured the resulting glass melt on a metal copper mold for rapid compression molding, and annealed at 350°C 3h to obtain a transparent precursor glass; then heat-treat the precursor glass at 650°C for 2 hours to obtain a transparent rare earth ion doped β-NaYF 4 Oxyfluorine glass-ceramics. Figure 4 It is the X-ray diffraction pattern of the glass-ceramic sample after heat treatment of sample S2, compared with the PDF c...

Embodiment 3

[0029] The glass composition (S3) of the present embodiment is: SiO 2 :60mol%, Al 2 o 3 :5mol%, Na 2 O: 18mol%, NaF: 7mol%, YF 3 :10mol%, ErF 3 : 0.5mol%, raw material selection of analytically pure SiO 2 、Al 2 o 3 、Na 2 CO 3 , NaF and spectrally pure YF 3 with ErF 3 . Weigh the raw material SiO according to the above mole percentage 2 :13.5529g,Al 2 o 3 : 1.9166g,Na 2 CO 3 : 7.1722g, NaF: 1.1050g, YF 3 :5.4850g,ErF 3 : 0.4215g, fully mixed evenly with a ball mill mixer, placed in a dense corundum crucible, melted at 1500°C for 1.5 hours; then poured the resulting glass melt on a metal copper mold for rapid compression molding, and annealed at 350°C 3h to obtain a transparent precursor glass; then heat-treat the precursor glass at 650°C for 3 hours to obtain a transparent rare earth ion doped β-NaYF 4 Oxyfluorine glass-ceramics. Figure 7 It is the X-ray diffraction pattern of the glass-ceramic sample after heat treatment of sample S3, compared with the PDF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com