Simultaneous proceeding method of online countercurrent roller changing and dynamic procedure changing for ESP finishing mill group

A technology of finishing rolling mills and changing procedures, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., and can solve problems such as steel loss and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

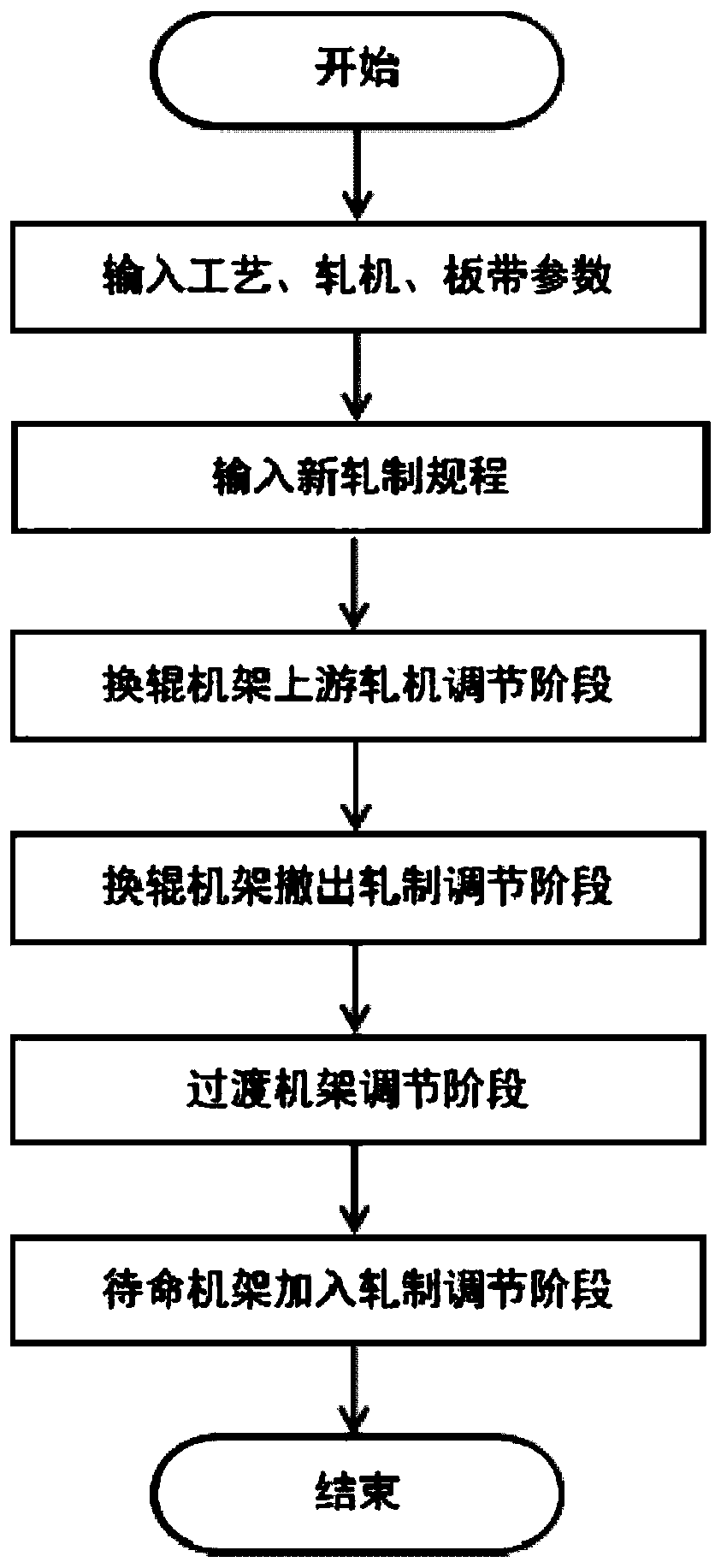

Method used

Image

Examples

Embodiment Construction

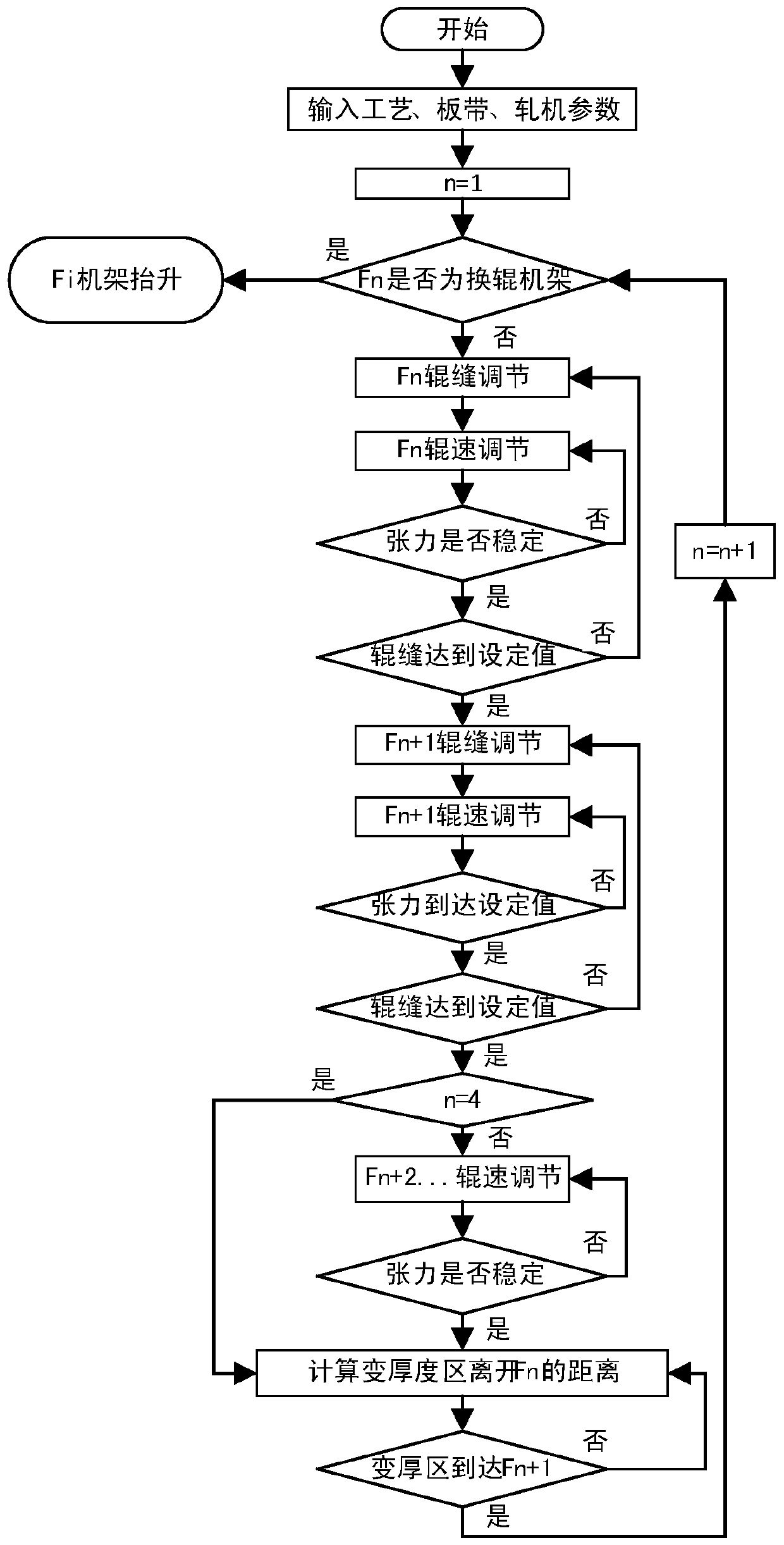

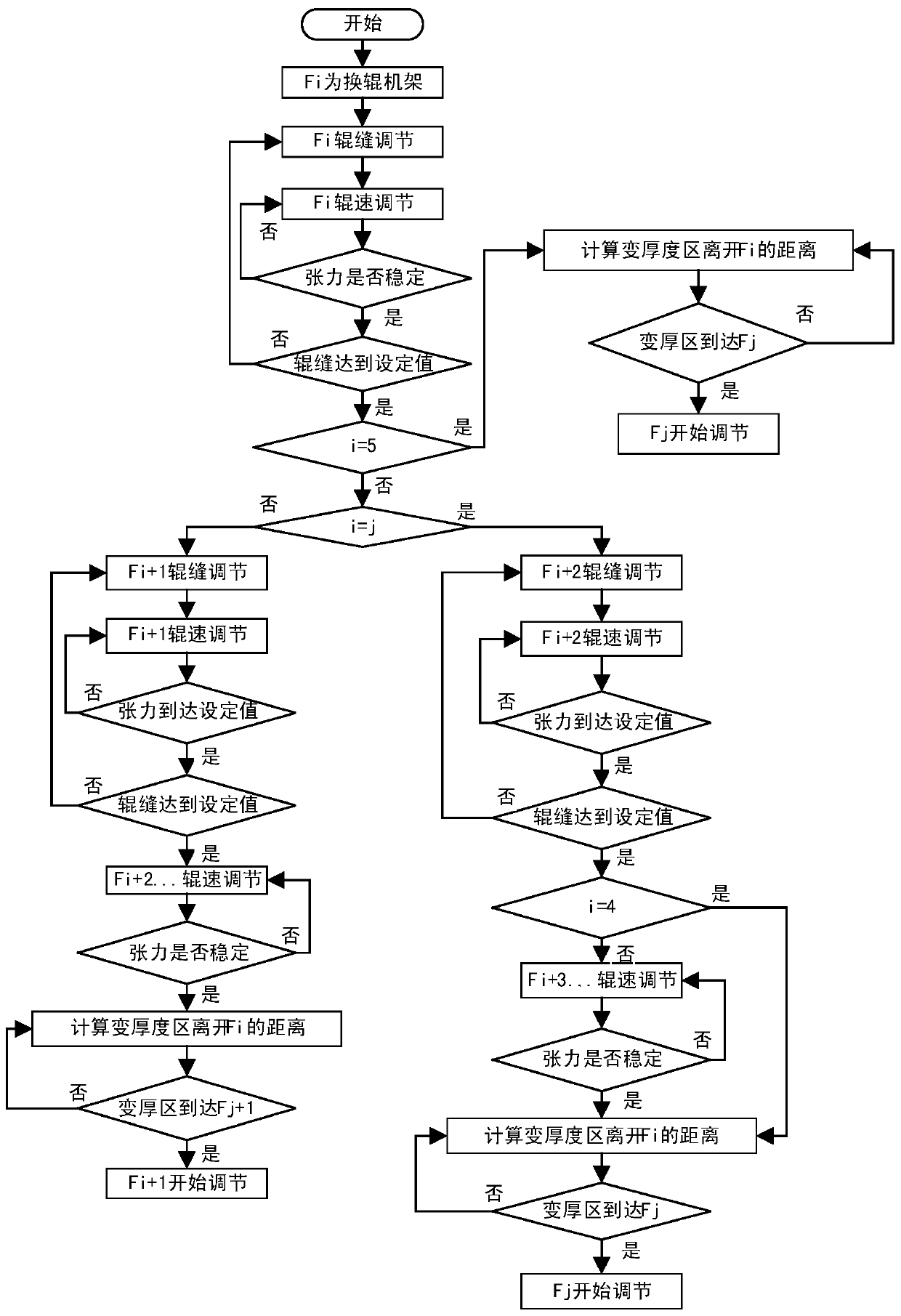

[0111] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. In the present invention, countercurrent on-line roll change means that the standby frame is behind the roll change frame, that is, the standby frame F j Replacement roll change stand F i , it must be j>i.

[0112] Take Rack F 3 As a roll changing rack, take rack F 5 As an example of a stand-by stand, the method of online roll change and dynamic program change is described simultaneously. The specification changes and schedule are shown in Table 1.

[0113] Table 1 Schedule

[0114]

[0115] As shown in Table 1, the stand-by rack F 5 Replacement roll change stand F 3 For example, at the same time, the specification of the rolling mill is changed from 0.9mm to 1mm, and the rolling procedure is switched from regulation one to regulation two. in rack F 5 Replace rack F 3 The process of dynamic change of rules is also realized.

[0116] refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com