Forkhead of universal coupling

A universal coupling, fork head technology, applied in the direction of coupling, elastic coupling, rigid shaft coupling, etc., can solve the problems of large cutting amount, reduced fork head strength, and easy breakage of fork head, etc. achieve high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

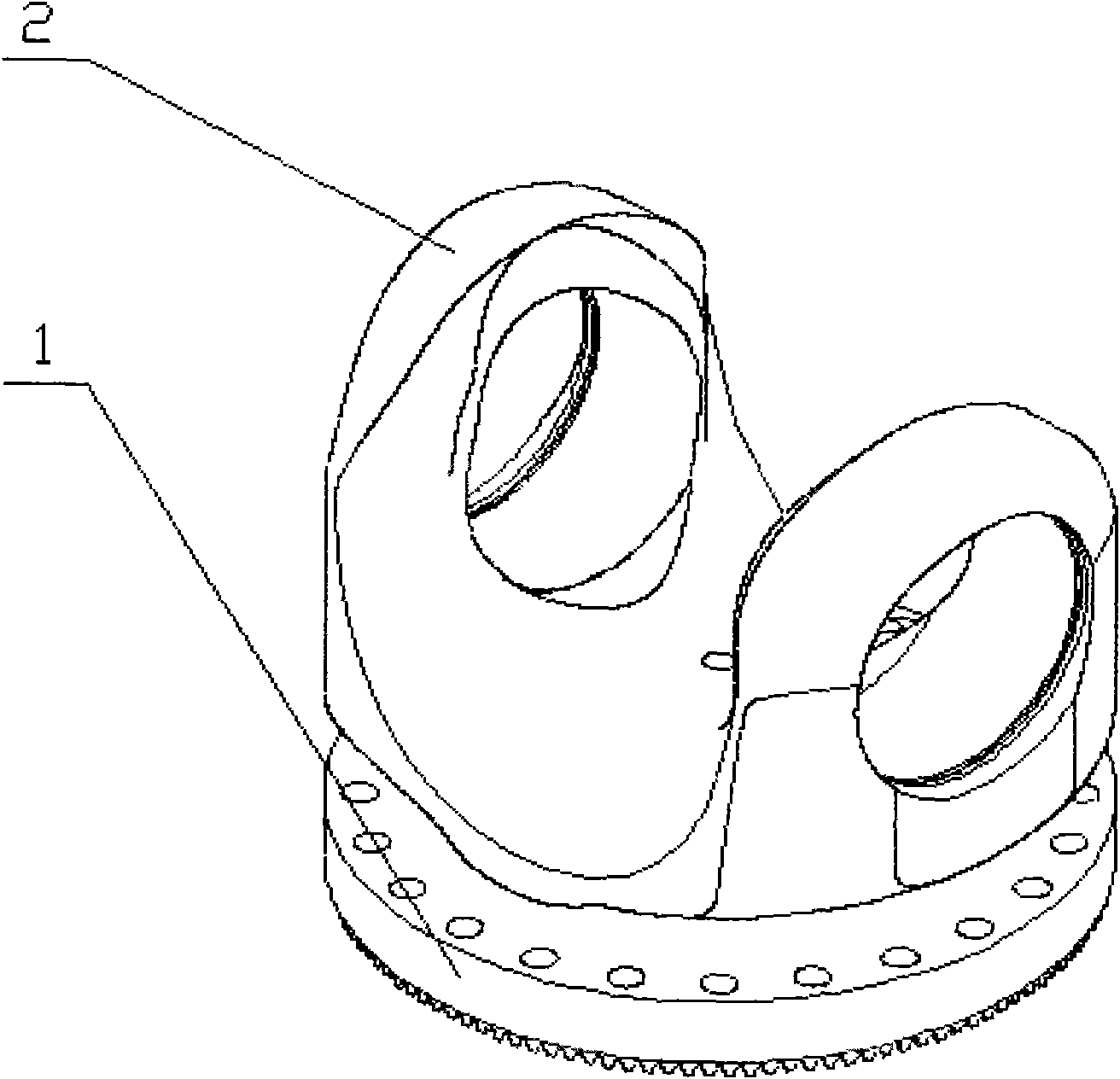

[0013] From figure 1 It can be seen that the fork head of the present invention has a base 1 for fixing the shaft, and a pair of parallel arms 2 extending from the base.

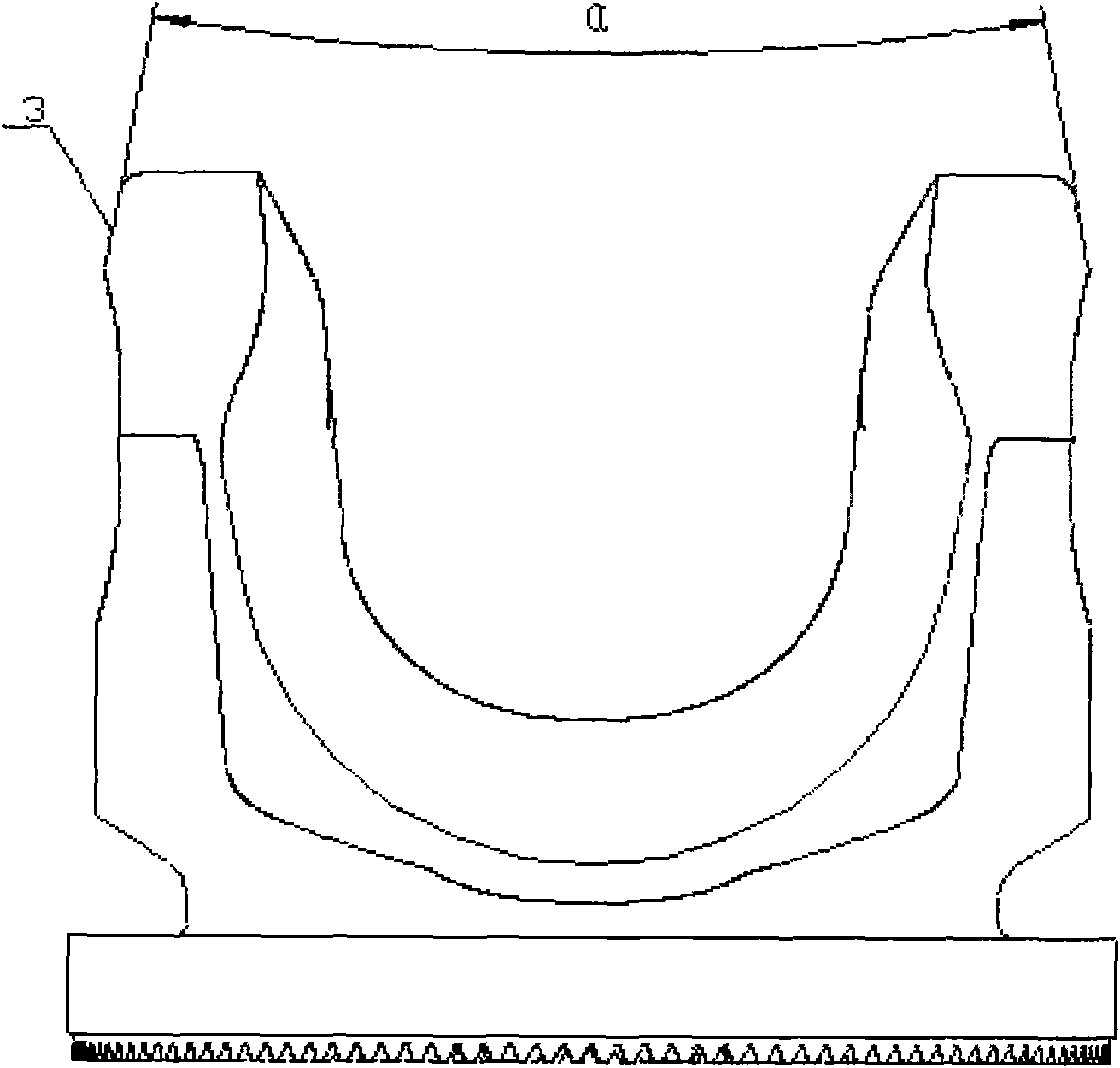

[0014] From figure 2 It can be seen that the top 3 of each arm 2 of the fork is a conical surface with an angle α; the angle of the cone is twice the limit angle of the fork. For example: when the cone angle α = 20 degrees, the limit angle of the fork is 10 degrees, that is to say figure 2 The yoke shown in the yoke will not exceed the turning diameter of the yoke itself within a range of 10 degrees of inclination.

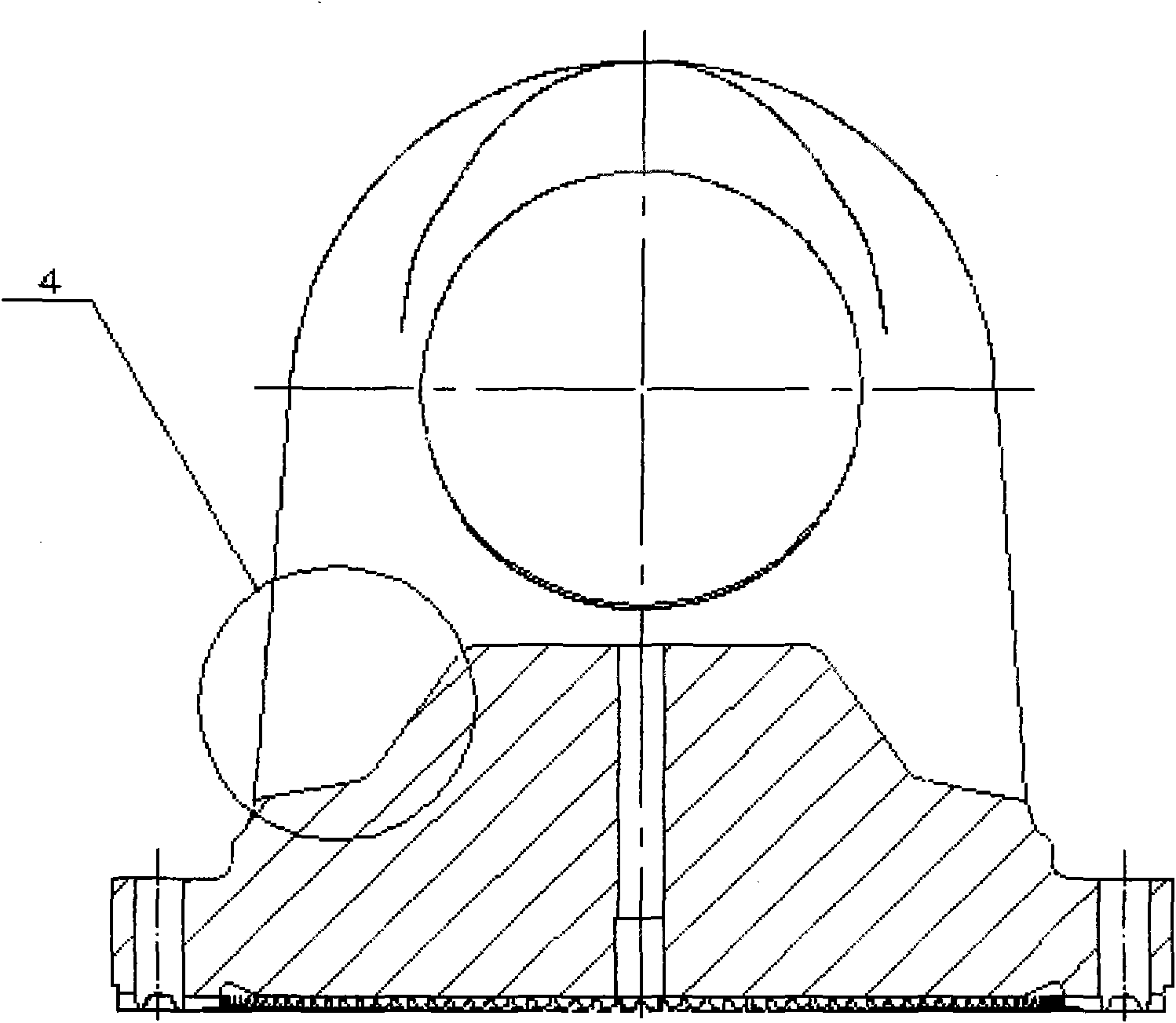

[0015] From image 3 It can be seen that the cut-off size of the bottom 4 of the internal cavity of the fork is determined by the relative size of the top 3 of the arm plus a certain margin. In this way, while meeting the requirements of the inclination angle, the cutting amount of the top is minimized, so that the strength of the fork is maximized. From Figure 6 It can be seen that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com