Method for controlling mechanical properties of cold-rolling strip steel in online manner

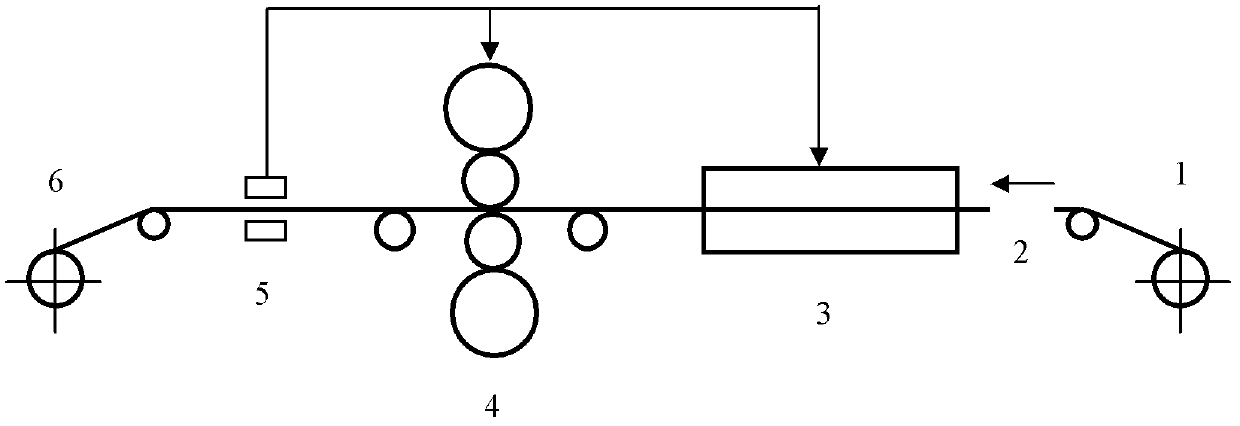

A technology of mechanical properties and cold-rolled strip steel, which is applied in the direction of rolling mill control device, rolling force/roll gap control, metal rolling, etc., and can solve problems such as inability to immediately detect strip steel, discontinuity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

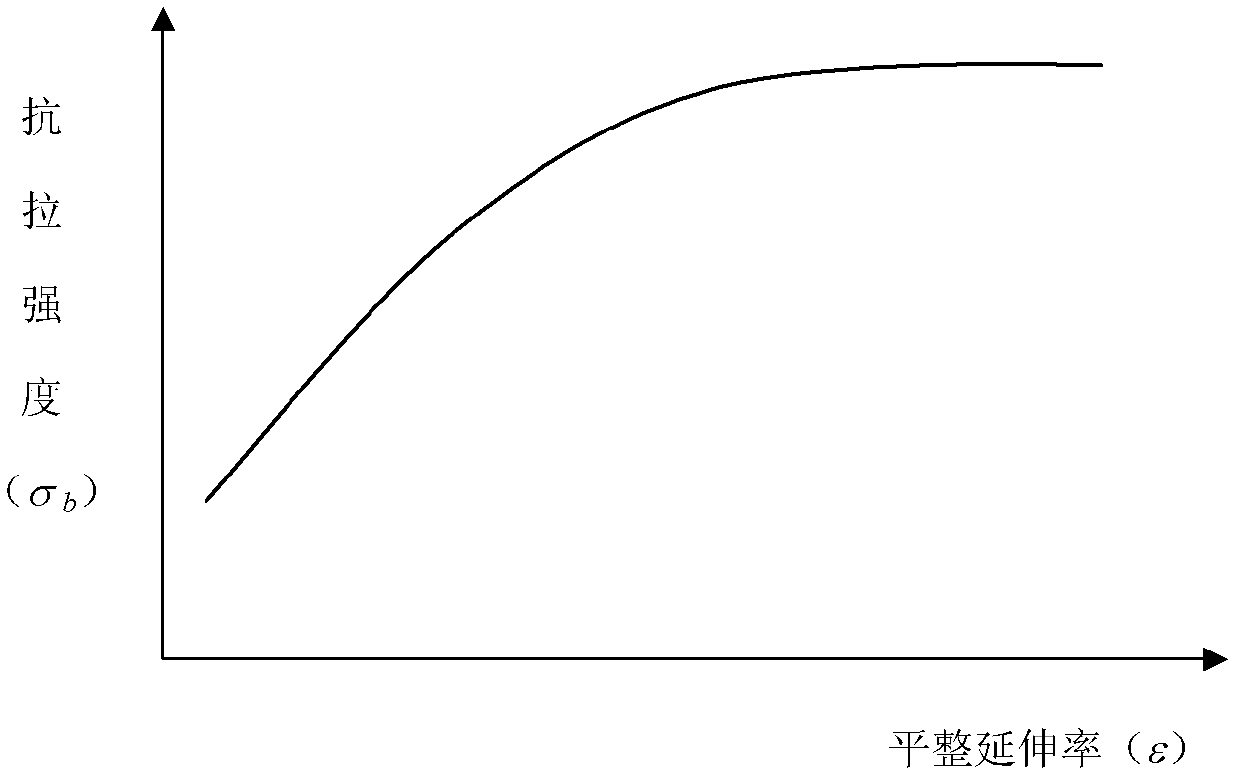

[0095] For products that require relatively high precision control of strip tensile strength, such as high-strength cold-rolled automotive sheets, combined with Figure 7 , the implementation steps and implementation methods of the strip steel tensile strength automatic control will be described in detail below. Proceed as follows:

[0096] (1) Determination of strip tensile strength deviation

[0097] The measured value σ of the strip tensile strength obtained by the mechanical performance tester 5 b_act Subtract the set tensile strength target value σ b_ref , get strip tensile strength deviation value Δσ b :

[0098] Δσ b = σ b_act -σ b_ref

[0099] where Δσ b is the strip hardness deviation value

[0100] σ b_ref The target value of strip tensile strength set for is obtained from the process control computer L2 of the unit and determined according to the requirements of downstream users for the product.

[0101] (2) Determine the strip leveling tension adjustmen...

Embodiment 2

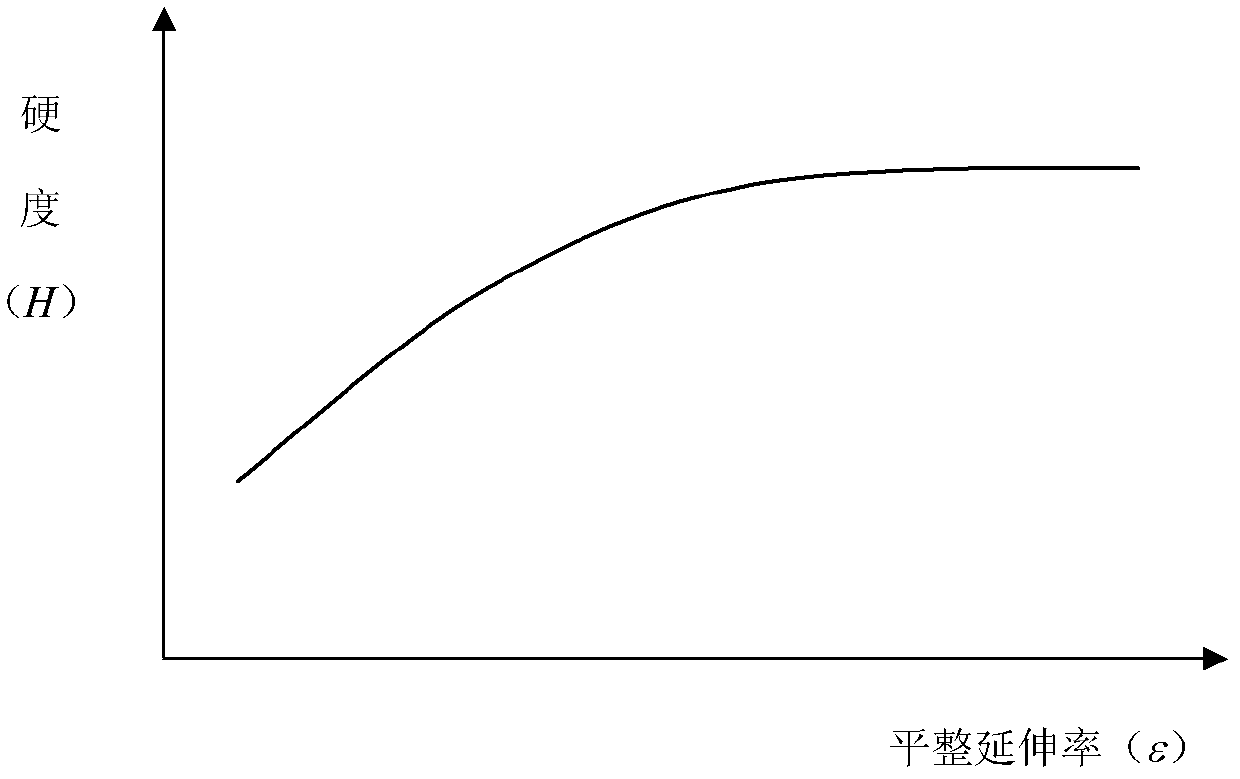

[0144] For cold-rolled steel strip products such as tinplate, etc., which require relatively high precision in strip hardness control, with reference to Figure 9, the implementation steps and methods of automatic control of strip hardness will be described in detail below. Proceed as follows:

[0145] (1) Determination of strip hardness deviation

[0146] The measured value H of the strip hardness obtained by the mechanical property detector 5 act Subtract the set hardness target value H ref , to get the strip hardness deviation value ΔH:

[0147] ΔH=H act -H ref

[0148] In the formula, ΔH is the deviation value of strip hardness

[0149] h ref The target value of strip hardness set for , comes from the process control computer L2 of the unit, and is determined according to the requirements of downstream users for products.

[0150] (2) Determine the strip leveling tension adjustment amount:

[0151] For strips with thinner thickness, since adjusting the leveling ten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com