Method of producing cylinder block and cylinder sleeve by friction stir welding

A technology of friction stir welding and friction stir, which is applied in the direction of manufacturing tools, cylinders, cylinder heads, etc., can solve problems such as difficult to weld cylinder liners, and achieve good mechanical strength, rigidity, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0173] A top-closed cylinder block made when the cylinder liner is joined to the cylinder block main body and a friction stir welding method for joining the cylinder liner to the cylinder block main body will be described in detail below with reference to the accompanying drawings. Preferred embodiment of the cylinder liner.

[0174] First, the first embodiment will be described below.

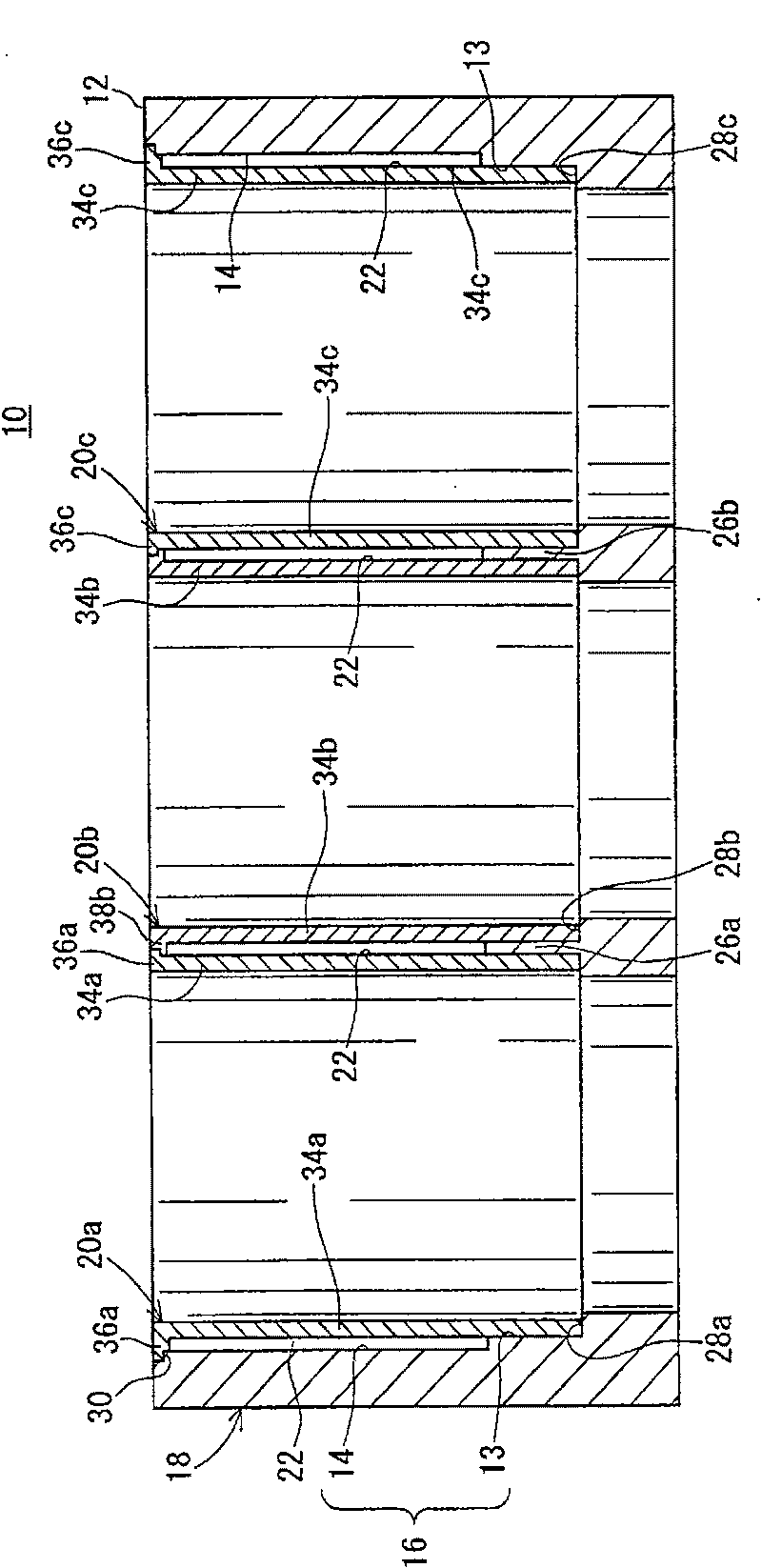

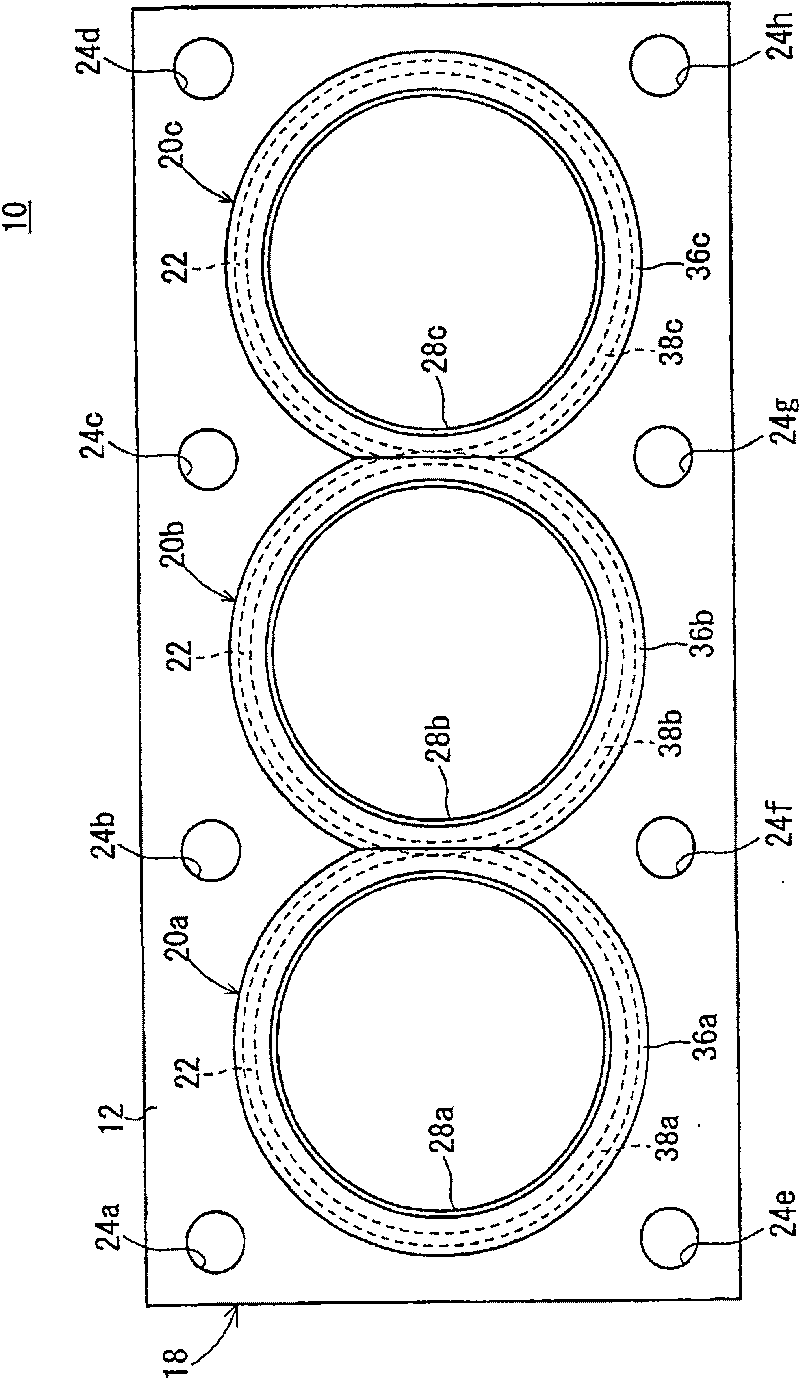

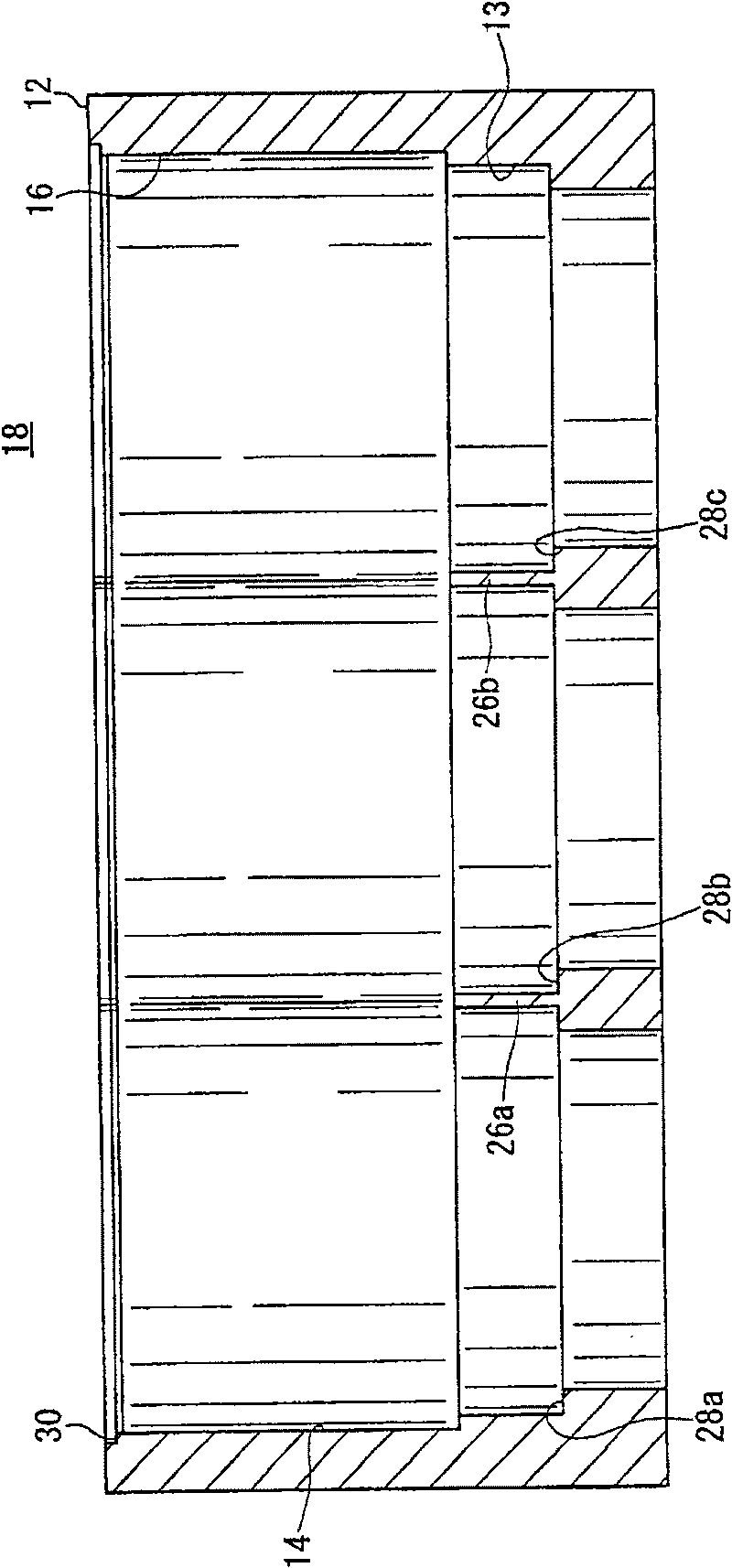

[0175] figure 1 is a vertical sectional view of the cylinder block 10 according to this first embodiment, and figure 2 is a plan view of the cylinder block 10 viewed from the gasket surface 12 as its upper end surface. The cylinder block 10 includes: a cylinder block main body 18 made of aluminum and having a communicating hole (cylinder bore) 16 including a first annular recess 13 and a second annular recess 14; cylinder liners 20a to 20c, which inserted into the communication hole 16 and engaged on the cylinder block main body 18; and a water jacket 22 to which coolant for cooling the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com