Dynamic variable regulation method based on ESP finishing mill group roll withdrawal

A technology of finishing rolling unit and variable schedule, which is applied in the direction of metal rolling stand, metal rolling mill stand, rolling force/roll gap control, etc., and can solve roll wear, affect production quality and production efficiency, frequent roll change, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

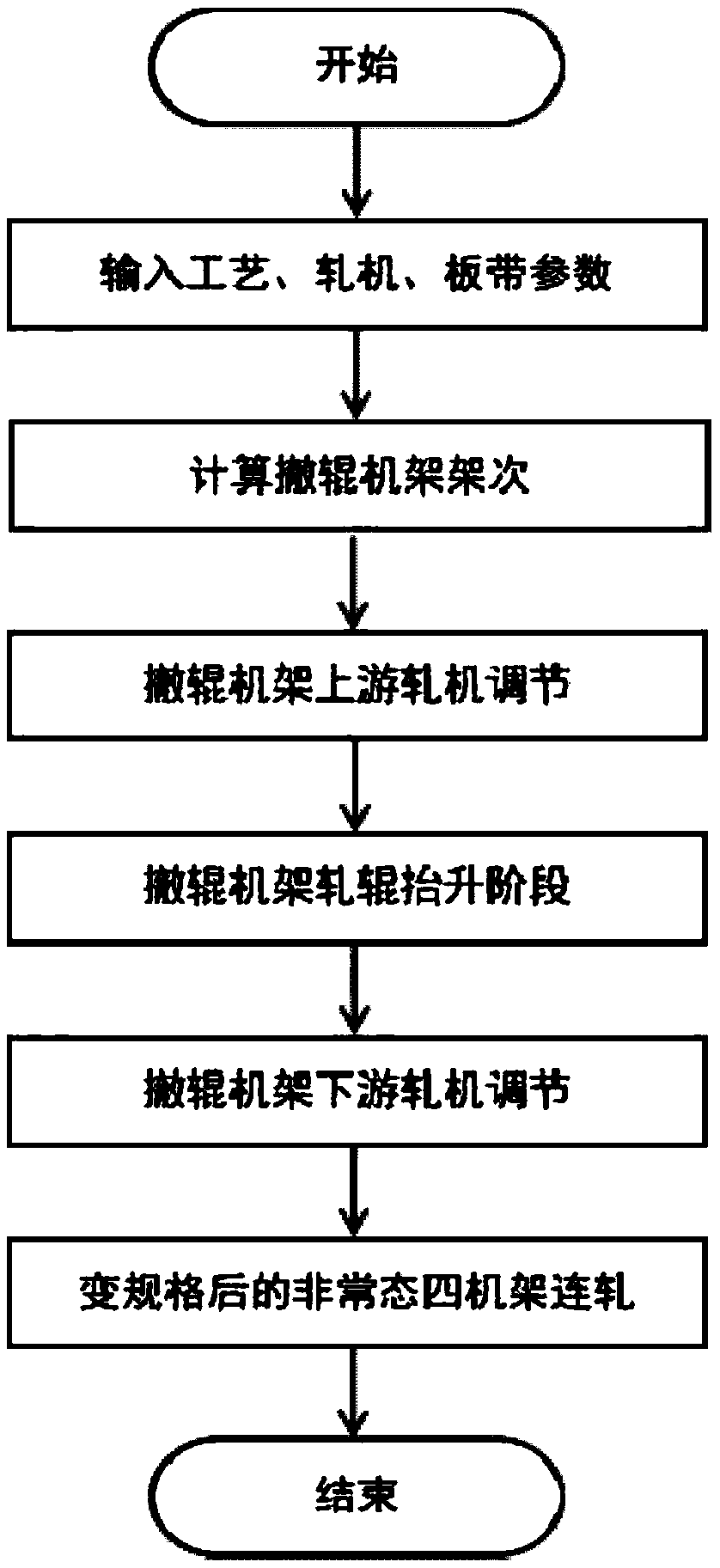

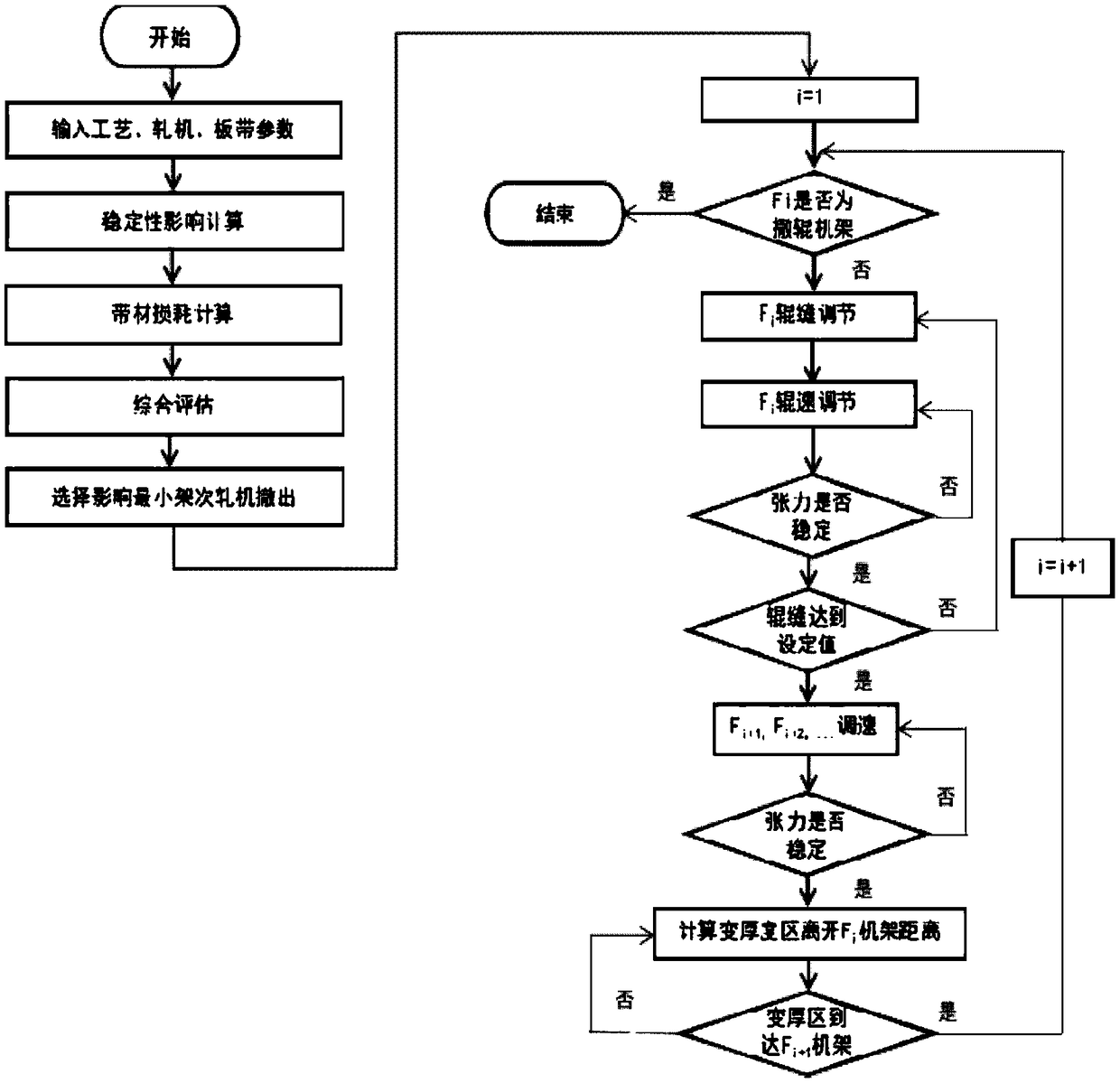

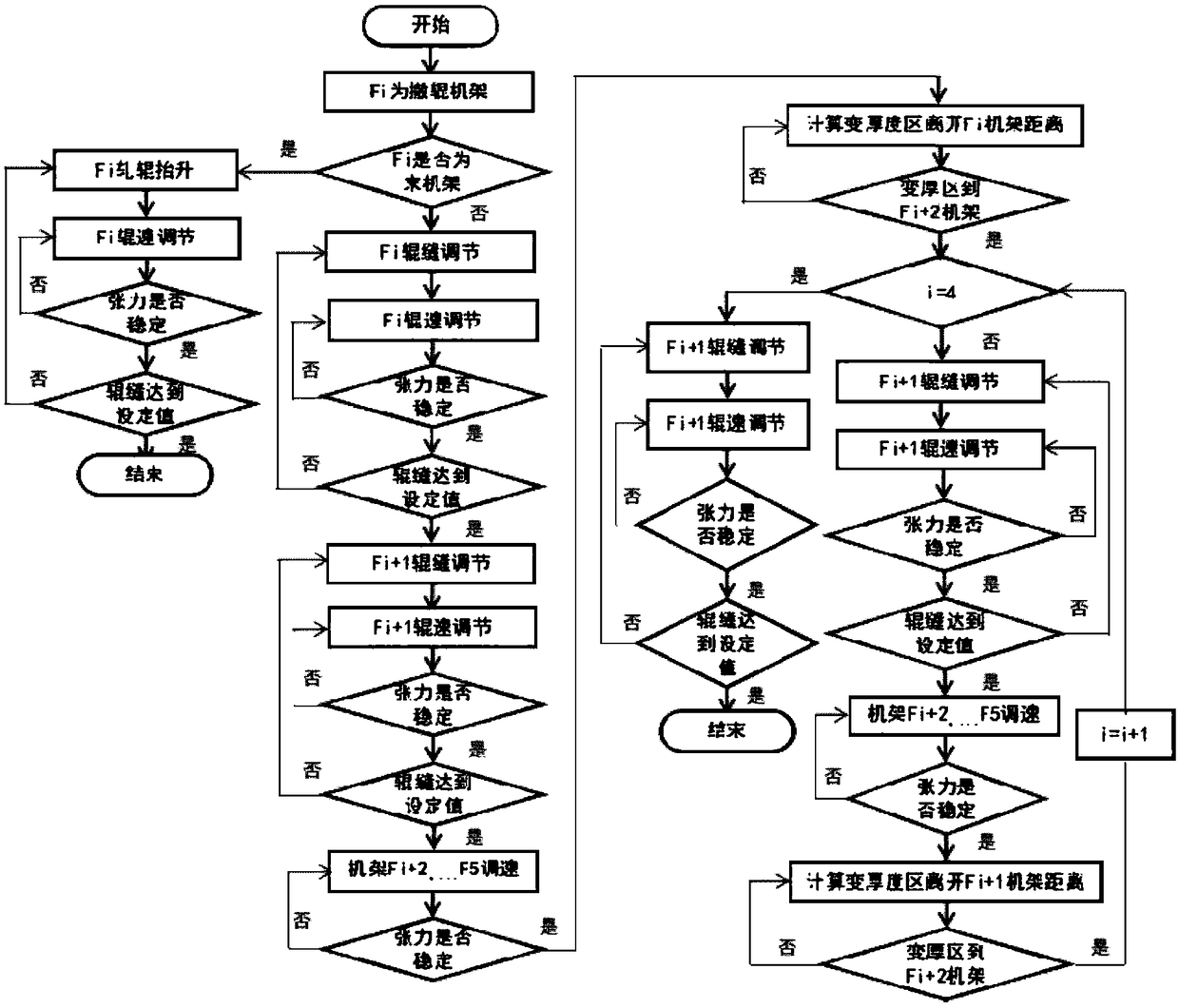

[0091] The present invention aims to provide a dynamic variable procedure method based on ESP finishing rolling roll withdrawal, that is, to determine the order of withdrawal of a stand through strategy calculation, and to transition the original normal five-stand rolling procedure to the abnormal four-stand rolling procedure. Stand rolling regulation, the present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0092] Take the roll stand F 5 As an example, see Table 1 and Table 2 for specification changes and schedules. Table 1 is the schedule before roll removal, and Table 2 is the schedule after roll removal.

[0093] Table 1 Procedure Table 1

[0094]

[0095] Table 2 Procedure Table 2

[0096]

[0097] As shown in Table 1, take the roller stand F 5 Taking online withdrawal rolling as an example, the specification of the rolling mill is changed from 1.0mm to 1.3mm, and the rolling schedule is switched from specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com