Integrated balance block and molding process thereof

A molding process and technology of balance weights, applied in the field of balance weights, can solve the problems of inconsistent slope of the fracture layer of the cut surface, material utilization rate of only 60%, and low aesthetics, so as to improve the convenience of operation, high material utilization rate, The effect of less scrap removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below, the technical solution of the present invention will be described in detail through specific examples.

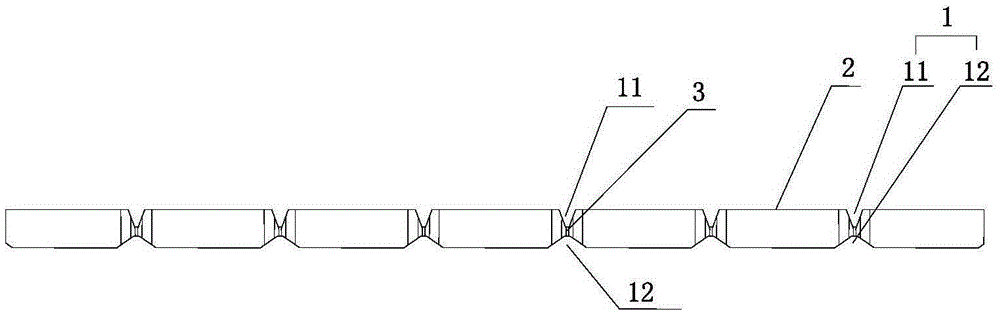

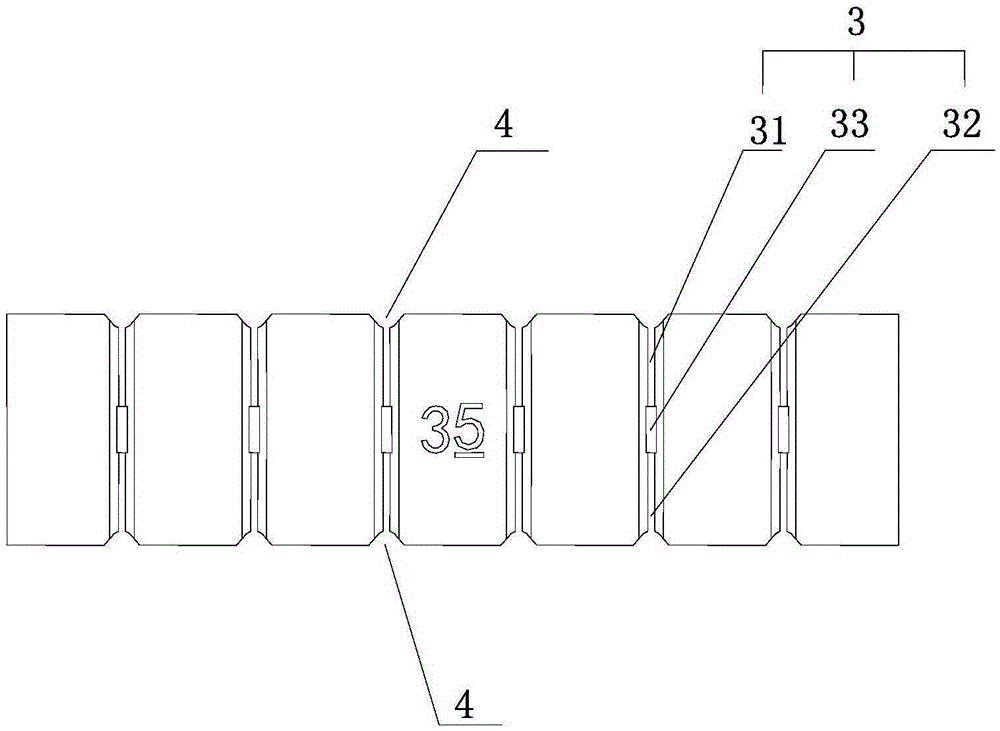

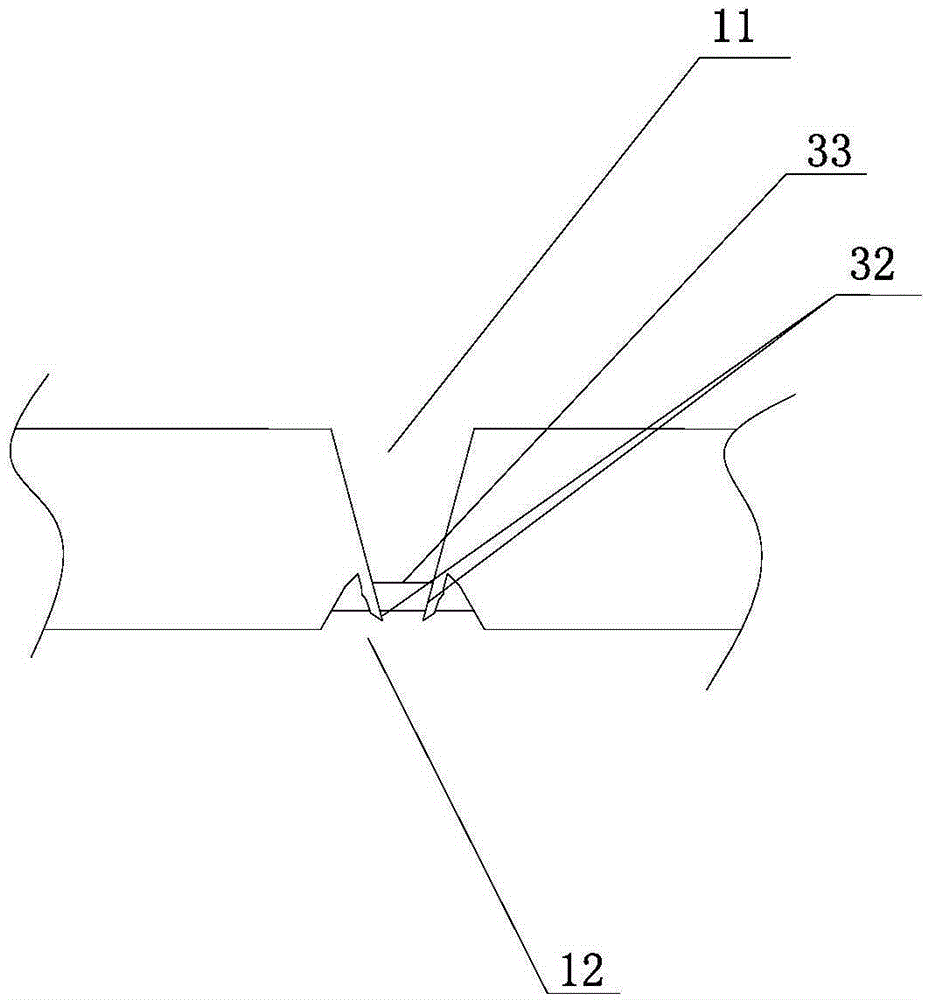

[0039] Such as Figure 1-7 as shown, figure 1 It is a structural schematic diagram of an integral balance weight proposed by the present invention; figure 2 A top view of an integral balance weight proposed by the present invention; image 3 It is a schematic diagram of the relationship between the second tearing belt and the connecting belt in an integral balance weight proposed by the present invention; Figure 4 It is an effect diagram of an integral balance weight proposed by the present invention; Figure 5 It is a schematic diagram of the processing of an integral balance weight proposed by the present invention; Figure 6 It is a schematic diagram of the force on the side of an integral balance weight proposed by the present invention during processing; Figure 7 It is a schematic diagram of force on the end face of an integral balance weight prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com