Lubricating oil composite stabilizer and stable hydrogenation lubricating oil composition

A composite stabilizer and lubricating oil technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of difficult operation, increased investment, high cost, etc., and achieve the goals of prolonging the service life, reducing the change of chromaticity, and reducing the total consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

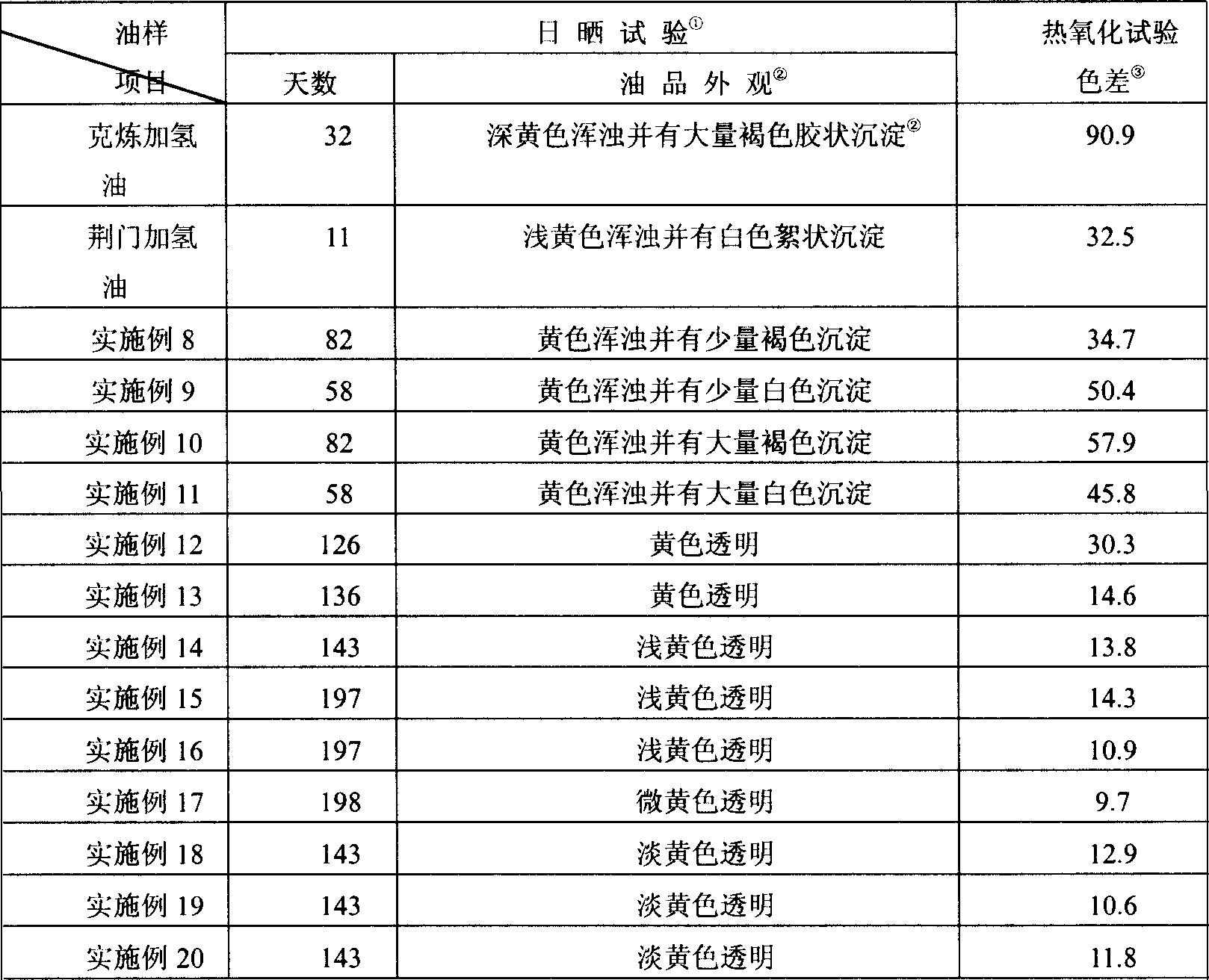

Examples

Embodiment 3

[0031] Embodiment 3 composite stabilizer-1

[0032] In a 100ml beaker, add 8.5g of zinc dibutyl dithiophosphate, 7.0g of octyl / butyl alkylated diphenylamine, and 8.5g of isooctyl 3,5-di-tert-butyl-4-hydroxyphenyl acrylate , 2-(2'-hydroxy-3',5'-di-tert-butyl)benzotriazole 15.5g, bis(2,2,6,6-tetramethylpiperidinyl) sebacate 15.5g 1. Put 6.0g of trinonylphenyl phosphite on the heater to heat, stir and mix with a glass rod, control the temperature at 80±5°C, keep for 30min., make the material uniform, and obtain a transparent light yellow liquid.

Embodiment 4

[0033] Embodiment 4 composite stabilizer-2

[0034] In a 100ml beaker, add 2,6-di-tert-butyl-p-cresol 9.0g, 3,5-di-tert-butyl-4-hydroxyphenylisooctyl acrylate 12.0g, 2-(2'-hydroxy-3 ', 5'-di-tert-butyl) benzotriazole 21.3g, ethyl bis(2,2,6,6-tetramethylpiperazinone) 5.8g, N-triacetic acid (2,2,6, 7.7g of 6-tetramethyl-4-piperidinyl) ester and 4.2g of trinonylphenyl phosphite were heated on a heater, stirred and mixed with a glass rod, and the temperature was controlled at 80±5°C for 30min. Make the material uniform to obtain a transparent light yellow liquid.

Embodiment 5

[0035] Embodiment 5 composite stabilizer-3

[0036] In a 100ml beaker, add 6.0g of octyl / butyl alkylated diphenylamine, 6.0g of zinc diisooctyl dithiophosphate, 6.8g of 2,6-di-tert-butyl p-cresol, 2-(2' -Hydroxy-3',5'-di-tert-butyl)benzotriazole 15.0g, 2-hydroxy-4-n-octyloxy-benzophenone 9.4g, bis(1,2,2,6,6 - Pentamethyl-4-piperidinyl) sebacate 12.2g, triphenyl phosphite 5.4g, heat on a heater, stir and mix with a glass rod, control the temperature at 60±5°C, and keep it for 30min. Make the material uniform to obtain a transparent light yellow liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com