Nylon 66 impregnated ingredient and method of producing long glass fiber reinforced nylon 66 aggregate by utilizing ingredient

A long glass fiber and nylon technology, used in the production of nylon 66 pellets, can solve the problems of high melt viscosity and difficult to penetrate glass fiber tow, etc., and achieve low melt viscosity, good thermo-oxidative stability, and good matrix toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

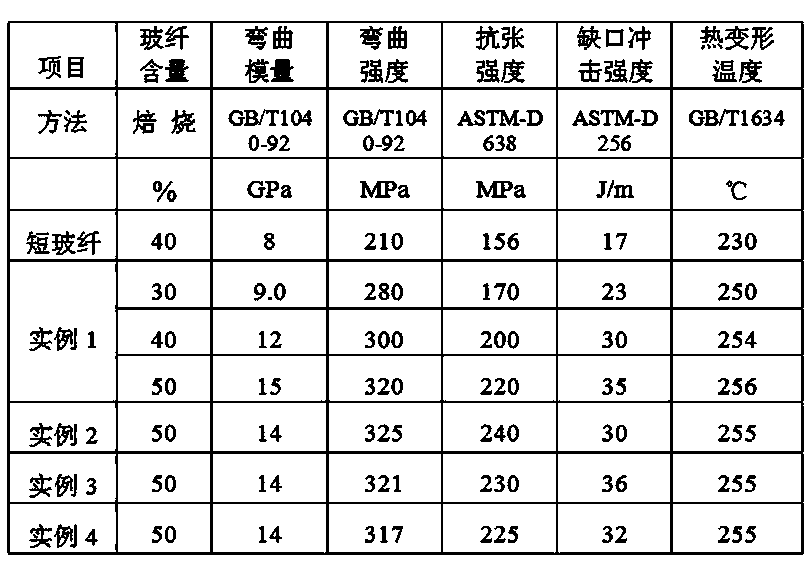

Examples

Embodiment 1

[0026] Nylon 66 dipping ingredients 1: Nylon 66 FYR 27 100 parts, compatibilizer POE-g-MAH 4 parts, coupling agent KH561 0.8 parts, zinc humate 0.8 parts, antioxidant 168 0.4 parts, antioxidant 1098 0.4 parts share. The temperatures of the feeding section, plasticizing section and compression section of the extruder are 220°C, 290°C and 310°C respectively. Nylon 66 ingredient 1 is extruded into a 310°C dipping die through a hot runner after being plasticized in the extruder. The glass fiber tow ER4301 is preheated from room temperature to 210°C and enters the dipping die, and is impregnated with nylon 66 melt at 310°C through the combined dipping die godet roller, and the dipped tow is cooled in a water tank and cut into 12mm pellets.

Embodiment 2

[0028]Nylon 66 dipping ingredients 2: Nylon 66 FYR 27 100 parts, compatibilizer POE-g-MAH 4 parts, coupling agent KH561 0.8 parts, zinc humate 0.4 parts, calcium stearate 0.4 parts, antioxidant 168 0.4 parts , 0.4 parts of antioxidant 1098, 0.2 parts of antioxidant DLTDP. The temperatures of the feeding section, plasticizing section and compression section of the extruder are 220°C, 290°C and 310°C respectively. Nylon 66 ingredient 2 is extruded into a 310°C dipping die through a hot runner after being heated and plasticized by the extruder. The glass fiber tow ER4301 is preheated from room temperature to 210°C and enters the dipping die, and is impregnated with nylon 66 melt at 310°C through the combined dipping die godet roller, and the dipped tow is cooled in a water tank and cut into 12mm pellets.

Embodiment 3

[0030] Nylon 66 dipping ingredients 3: 100 parts of nylon 66 FYR 27B, 6 parts of compatibilizer 1901 SEBS-MA, 1.2 parts of coupling agent KH561, 0.4 parts of zinc humate, 0.4 parts of zinc calcium humate, 0.2 parts of silicone powder , Antioxidant 168 0.4, Antioxidant 1098 0.4, Antioxidant DLTDP 0.2. The temperatures of the feeding section, plasticizing section and compression section of the extruder are 220°C, 290°C and 310°C respectively. Nylon 66 ingredient 3 is extruded into a 310°C dipping die through a hot runner after being heated and plasticized by the extruder. The glass fiber tow ER4301 is preheated from room temperature to 210°C and enters the dipping die, and is impregnated with nylon 66 melt at 310°C through the combined dipping die godet roller, and the dipped tow is cooled in a water tank and cut into 12mm pellets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com