Heavy-load agricultural diesel engine special oil and production method thereof

A diesel engine and special oil technology, which is applied in the field of special oil for heavy-duty agricultural diesel engines, can solve the problems of easy oxidation and deterioration of oil products, sintering of engine parts, heavy engine load, etc., and achieve excellent thermal oxidation stability and oil-water separation, The effect of prolonging the lubrication protection ability and service life, and improving the thermal oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

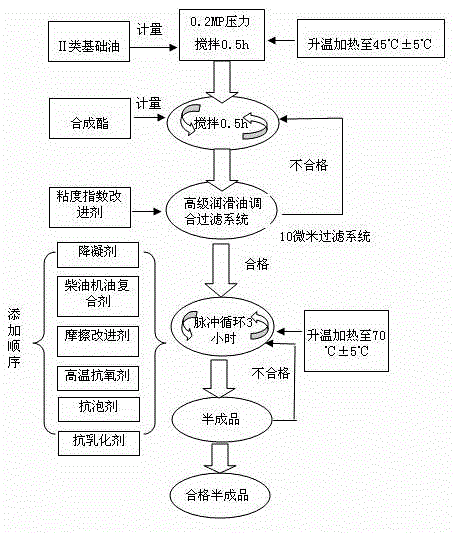

Method used

Image

Examples

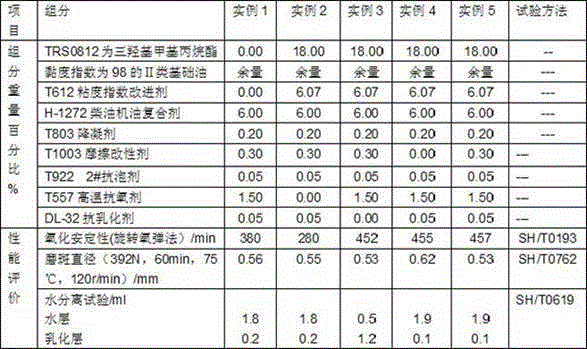

example 1

[0050] Example 1: This example is mainly to prepare CF-4 20W-50 diesel engine oil, which contains non-sulfur phosphorus organic boron molybdenum friction reducer, polyalphaolefin compound, polymethacrylate viscosity index improver, polymethacrylate Type pour point depressant, synthetic sulfonate, diesel engine oil compounding agent H-1272, octyl / butyl diphenylamine. The specific content groups of each component are shown in Table 1. Its production technology method is the same according to the above-mentioned technical process.

[0051] When the kinematic viscosity of 600N at 100°C is 12.05mm2 / s for Group II base oil, the 100°C kinematic viscosity of synthetic ester TRS0812 is 13.50mm2 / s, and the 100°C kinematic viscosity of T612 viscosity index improver is 3.8, the example product Satisfy the following formula, and its formula quantity is represented by percentage content.

[0052] Table 1:

[0053]

[0054] It can be seen from Table 1 that the API CF-420W-50 diesel e...

example 6

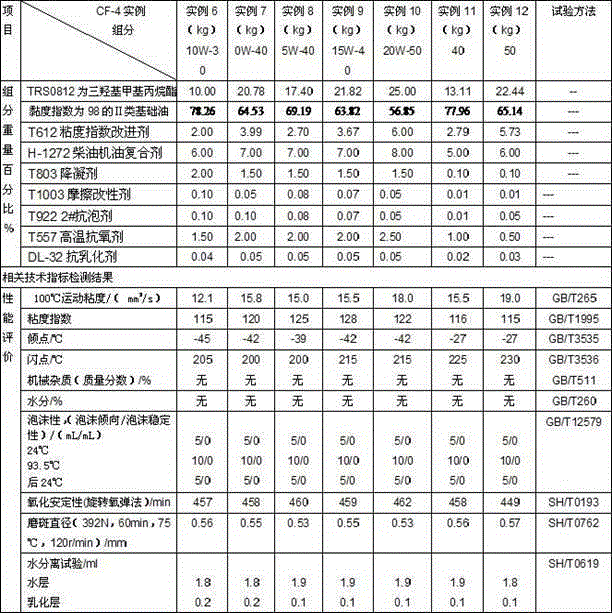

[0057] This example mainly deploys CF-4 10W-30 diesel engine oil

[0058] When the 100°C kinematic viscosity of 500N Ⅱ base oil is 10.0mm2 / s, the 100°C kinematic viscosity of synthetic ester TRS0812 is 12.5mm2 / s, and the 100°C kinematic viscosity of T612 viscosity index improver is 3.8. In this example, under the pressure of 0.2MP, the measured 500N 78.26kg of Group II base oil was transferred to a specific blending reactor, and the temperature was raised to 45°C ± 5°C after performing cold oil pulse stirring for 0.5 hours; According to the lubricating oil blending metering controller, transfer 10.00 kg of multi-component synthetic ester according to the metering number, and stir for 0.5 hours; then transfer the online blending oil and ester mixture to a 10-micron "advanced lubricating oil blending and filtering system" for 0.5 hours of circulation filtration, Make the mixture uniform and remove impurities; transfer 2.00 kg of the measured viscosity index improver into the ble...

example 7

[0060] This example mainly deploys CF-4 0W-40 diesel engine oil

[0061] When 600N 100°C kinematic viscosity is selected as Group II base oil, the 100°C kinematic viscosity of synthetic ester TRS0812 is 13.5mm2 / s, and the 100°C kinematic viscosity of T612 viscosity index improver is 3.8. The example formula includes: 64.53kg of 600N type II base oil, 20.78kg of multi-component synthetic ester, 3.99kg of viscosity index improver, 1.50kg of pour point depressant, 7.00kg of diesel engine oil compounding agent, 0.05kg of friction modifier, high temperature antioxidant 2.00kg, anti-foaming agent 0.10kg, anti-emulsifying agent 0.05kg, etc., the main configuration process is the same as example 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com