Refrigeration machine oil composition and application thereof

A refrigeration oil and composition technology, applied in the field of lubricating oil, can solve the problems of poor high-temperature thermochemical stability, low-temperature fluidity, and limited scope of application of refrigerants, and achieve good chemical stability, high viscosity index, and low flocculation point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

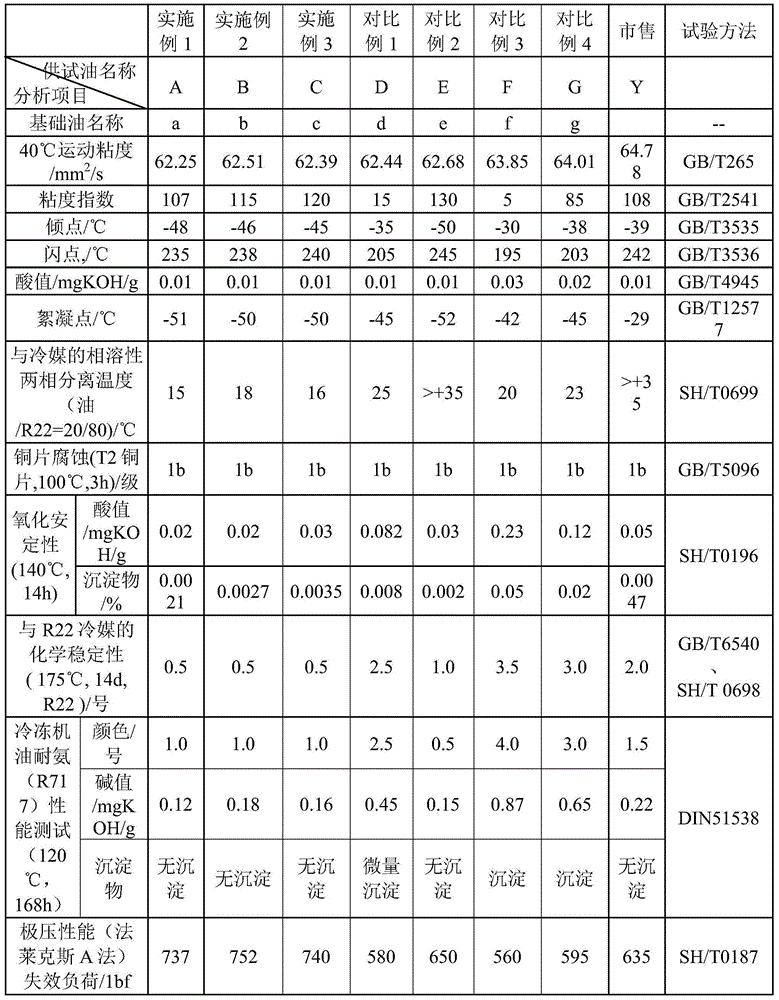

Examples

Embodiment 1

[0042] Use 47% polyalphaolefin synthetic engine oil second-line oil (from China Petroleum Lanzhou Lubricating Oil Factory), 50% naphthenic high-pressure hydrogenation minus third-line mineral oil (from Karamay Petrochemical Company), and then add 3% boiling point at 250 ° C Above, 100℃ kinematic viscosity 7.42mm 2 / s, pour point -42°C, viscosity index of 105 alkylbenzene synthetic base oil, adjusted to kinematic viscosity of 62.57mm at 40°C 2 / s base oil a.

Embodiment 2

[0044] Use 67% polyalphaolefin synthetic engine oil third-line oil (from China Petroleum Lanzhou Lubricating Oil Factory), 30% naphthenic high-pressure hydrogenation minus third-line mineral oil (from Karamay Petrochemical Company), and then add 3% boiling point at 250 ° C Above, 100℃ kinematic viscosity 7.42mm 2 / s, pour point -42°C, viscosity index of 105 alkylbenzene synthetic base oil, adjusted to kinematic viscosity of 62.93mm at 40°C 2 / s base oil b.

Embodiment 3

[0046] Use 55% polyalphaolefin synthetic engine oil PAO8 (from commercially available Mobil products), 42% naphthenic high-pressure hydrogenation minus second-line and minus three-line mineral oils (from Karamay Petrochemical Company), and then add 3% boiling point at 250 ° C Above, 100℃ kinematic viscosity 7.42mm 2 / s, pour point -42°C, viscosity index of 105 alkylbenzene synthetic base oil, adjusted to kinematic viscosity of 62.85mm at 40°C 2 / s base oil c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com