Wide temperature range polyol ester lubricating oil composition suitable for aircraft engine

A technology for lubricating oil composition and aero-engine, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve problems such as difficulty in long-term operation, poor hydrolytic stability of lubricating oil, strong metal corrosion, etc., and achieve hydrolytic stability The effect of strong performance, excellent low temperature start-up performance and excellent lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

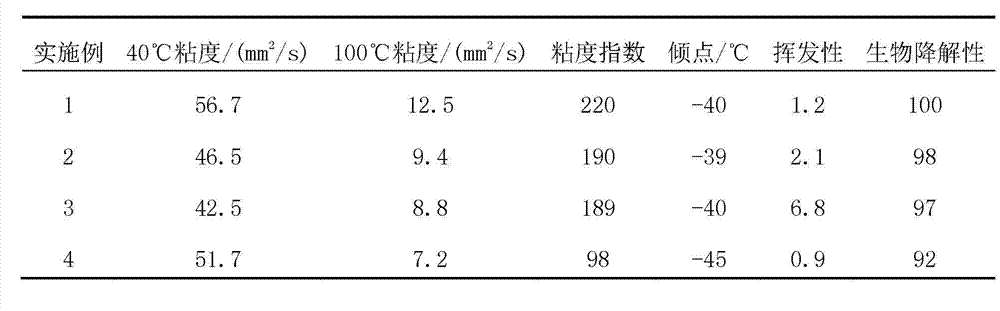

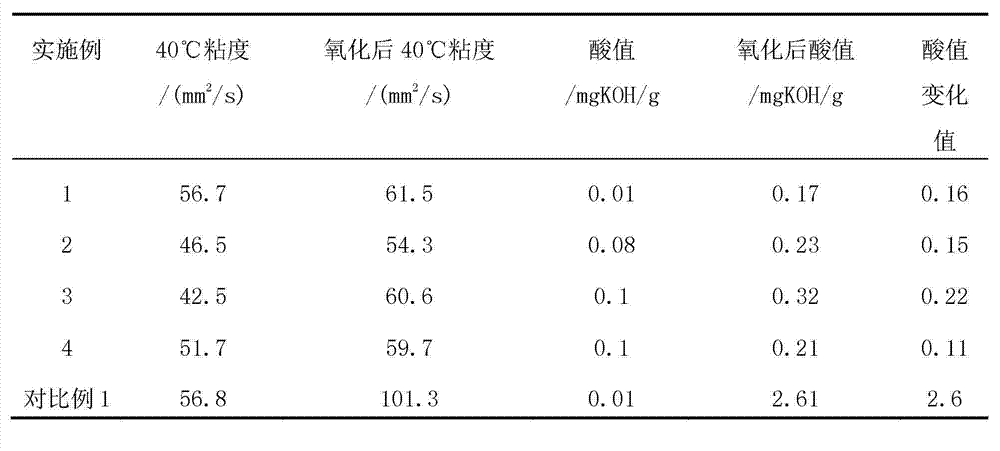

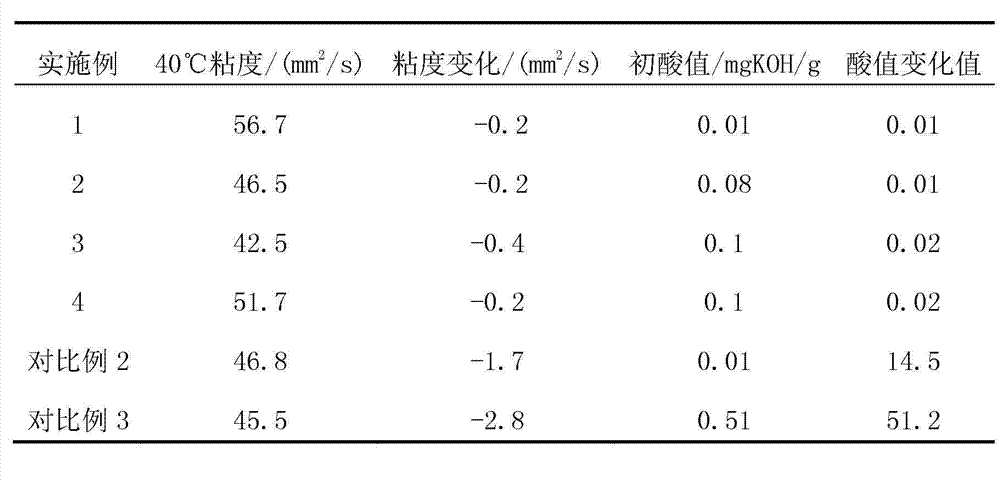

Embodiment 1

[0017] The aviation lubricating oil composition is composed of the following components in weight percentage: 90% pentaerythritol oleate, 5% di-tert-dodecyl polysulfide, 2,6-di-tert-butyl-4-hydroxyphenyl propionate 1%, polyisobutylene succinimide (product code T154A) 3%, mercaptobenzotriazole 1%. Add the above-mentioned measured compounds into a stirred reaction kettle in sequence, stir at room temperature for 3-5 hours, take a sample and visually inspect it for uniformity, and then discharge to obtain the product.

Embodiment 2

[0019] The aviation lubricating oil composition is composed of the following components in weight percentage: 70% pentaerythritol oleate, 24% pentaerythritol isooctanoate, 3% di-tertiary dodecyl polysulfide, 0.8% didodecyl diphenylamine , Thiophosphate polyisobutene barium salt (commodity code T108) 2%, propynyl alcohol 0.2%. The preparation method is the same as in Example 1.

Embodiment 3

[0021] The aviation lubricating oil composition is composed of the following components in weight percentage: 85% trimethylolpropane oleate, 8% pentaerythritol enanthate, 4% di-tert-dodecyl polysulfide, 2,6-di-tert- Butyl p-cresol 1%, ultra-high base value synthetic magnesium sulfonate (product code T107) 1%, sarcosinate lauryl 1%. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com