Lubricating oil compound and preparation method thereof

A technology of lubricating oil composition and compound, applied in the field of lubricating oil, can solve the problems of extreme pressure and anti-wear of lubricating oil, stumbling, abnormal noise and jitter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a kind of preparation method of lubricating oil composition, comprises the following steps:

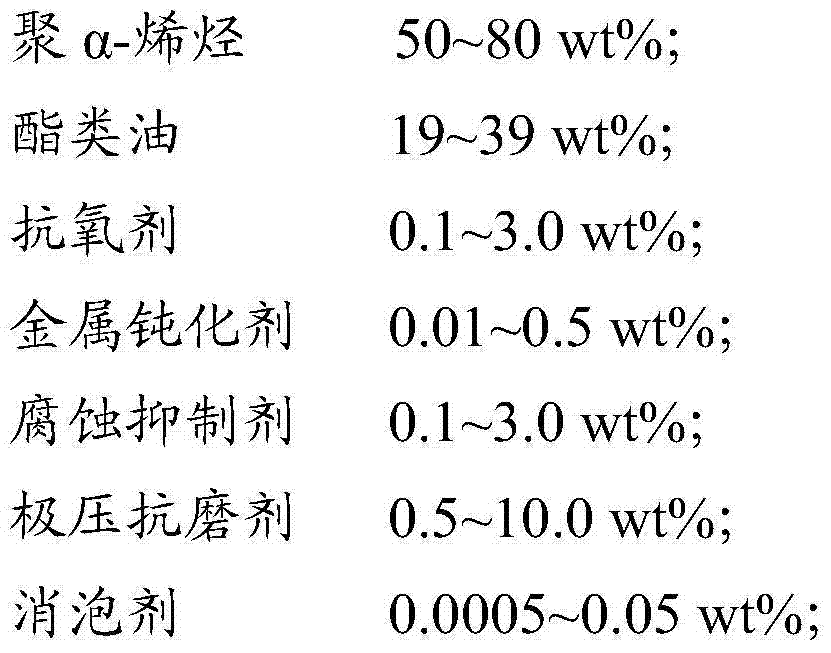

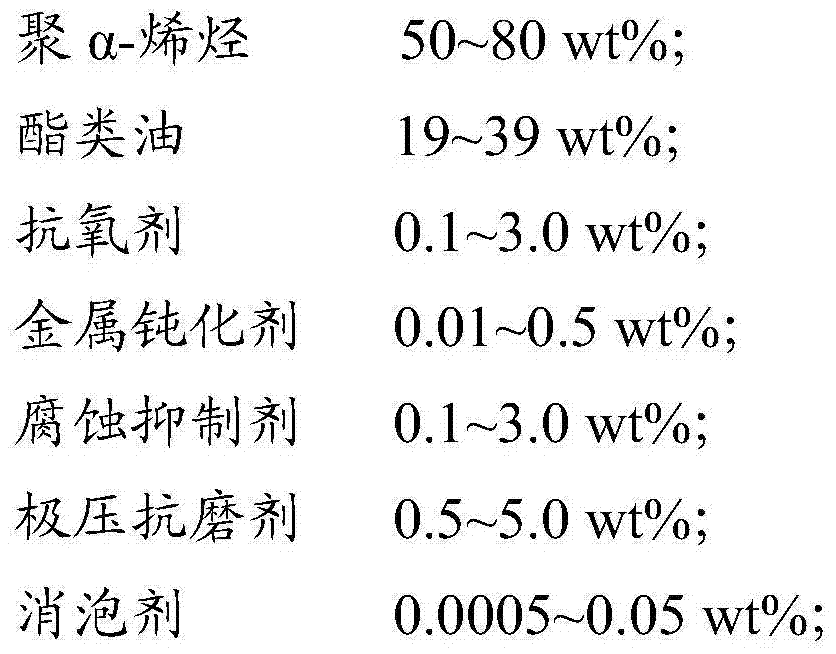

[0044] 50-80wt% polyalphaolefin, 19-39wt% ester oil, 0.1-3.0wt% antioxidant, 0.01-0.5wt% metal passivator, 0.1-3.0wt% corrosion inhibitor , 0.5-5.0wt% of extreme pressure anti-wear agent and 0.0005-0.05wt% of anti-foaming agent are mixed and stirred evenly to obtain a lubricating oil composition.

[0045] The metal deactivator is selected from one or more of benzotriazole derivatives, thiadiazole derivatives and organic amine compounds; the corrosion inhibitor is selected from fatty acids, fatty acid derivatives, sulfonates and compound One or more of phosphate compounds; the corrosion inhibitor is selected from one or more of fatty acids, fatty acid derivatives, sulfonates and complex phosphate compounds; the extreme pressure antiwear agent is selected from One or more of phosphate compounds, phosphite compounds, organic sulfides, phosphoru...

Embodiment 1

[0052] 3wt% of dialkyldithiocarbamate, 2wt% of bisphenol-type antioxidant 4702, 0.1wt% of N,N-dialkylaminomethylene benzotriazole, 5wt% Organic molybdate, 0.3wt% barium dinonylnaphthalene sulfonate and 0.001wt% methyl silicone oil (5000) were sequentially added to 55wt% polyα-olefin PAO10 and the rest of ester oil (SH5102), Stir evenly under the conditions of 110° C. and 80 Pa to obtain a lubricating oil composition.

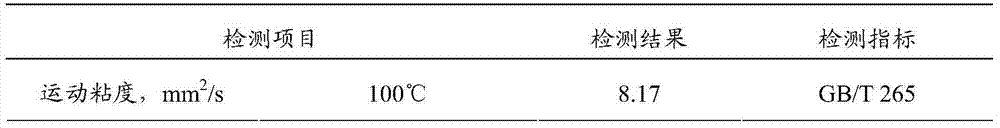

[0053] The performance of the lubricating oil composition obtained in Example 1 was tested, and the results obtained are shown in Table 1.

[0054] The performance detection result of table 1 embodiment 1 lubricating oil composition

[0055]

[0056]

Embodiment 2

[0058] 3wt% of dialkyldithiocarbamate, 2wt% of bisphenol-type antioxidant 4702, 0.1wt% of N,N-dialkylaminomethylene benzotriazole, 5wt% Organic molybdate, 0.3wt% barium dinonylnaphthalene sulfonate and 0.0015wt% methyl silicone oil (5000) were sequentially added to 55wt% polyα-olefin PAO10 and the rest of ester oil (SH5102), Stir evenly under the conditions of 110° C. and 80 Pa to obtain a lubricating oil composition.

[0059] The performance of the lubricating oil composition obtained in Example 2 was tested, and the results obtained are shown in Table 2.

[0060] The performance detection result of table 2 embodiment 2 lubricating oil composition

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com