Lubricating oil composition having improved oxidation stability at high temperatures

a technology of lubricating oil and high temperature, which is applied in the preparation of carboxylic compounds, fuels, organic chemistry, etc., can solve the problems of deterioration and viscosity increase of lubricating oil, severe operation conditions of diesel engines for electric power generation and operation of marine vessels, and forced to employ low grade fuels with increased sulfur content, etc., to improve oxidation stability and improve high temperature oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0032] A lubricating oil composition (TBN: 30 mg•KOH / g, SAE viscosity grade: SAE 40) was prepared using the following additives and base oil:

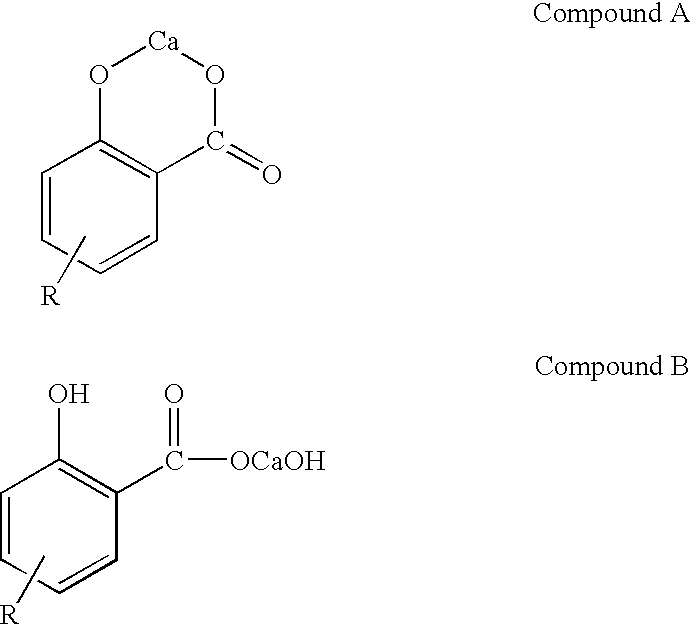

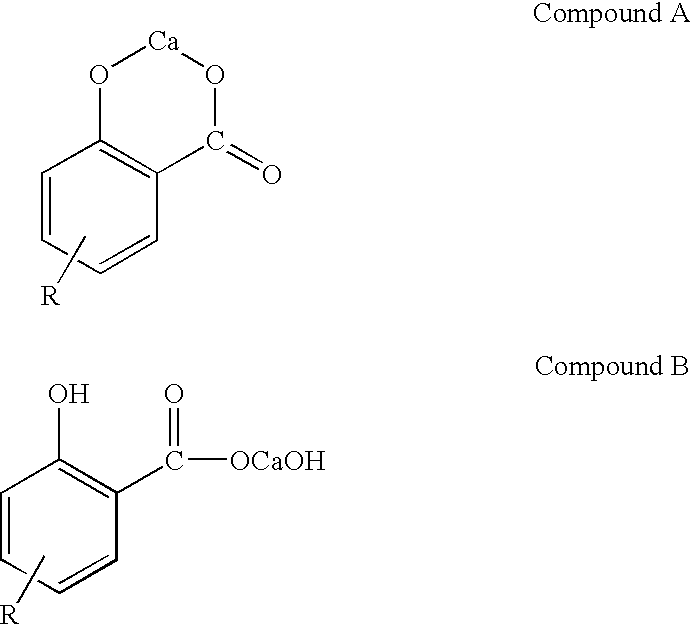

[0033] a) overbased calcium carboxylate (TBN: 145 mg•KOH / g, a mixture of a compound of the aforementioned formula in which R has 12 to 18 carbon atoms and a compound of the formula in which R has 20 to 28 carbon atoms, in a weight ratio of 50:50 in an amount of 1.15 wt % in terms of Ca content;

[0034] b) bis-structure succinimide dispersant (nitrogen content 0.018 wt %, prepared by reaction between polyalkylene polyamine (containing nitrogen atoms of 5.0 (mean number) in a molecule) and a product produced by thermal reaction of polybutene (number average molecular weight: approx. 1,000, having at least 50 mole % of methylvinylidene structure) and maleic anhydride) in an amount of 0.018 wt % in terms of N content;

[0035] c) zinc di(secondary)alkyldithiophosphate (P 0.049 wt %, Zn 0.054 wt %, S 0.14 wt %, prepared using a secondary alcohol conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

| lubricating viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com