Full-synthetic wind power generation gear oil

A gear oil, fully synthetic technology, applied in the field of lubricating oil, to achieve the effect of reducing surface fatigue, reducing the probability of contact collision, and large temperature difference in the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] Another aspect of the present invention provides a kind of preparation method of fully synthetic wind power generator gear box oil, comprises the steps:

[0071] Add 2 / 3 base oil into a clean reactor, and raise the temperature of the reactor to 60°C,

[0072] Add extreme pressure agent, friction reducer, antioxidant, dispersant and rust inhibitor in sequence,

[0073] After stirring for 30 minutes, add anti-emulsion agent and continue stirring for 30 minutes;

[0074] Add the remaining 1 / 3 base oil into the reactor and lower the temperature to 35°C;

[0075] The product is obtained after being filtered by a filtering device.

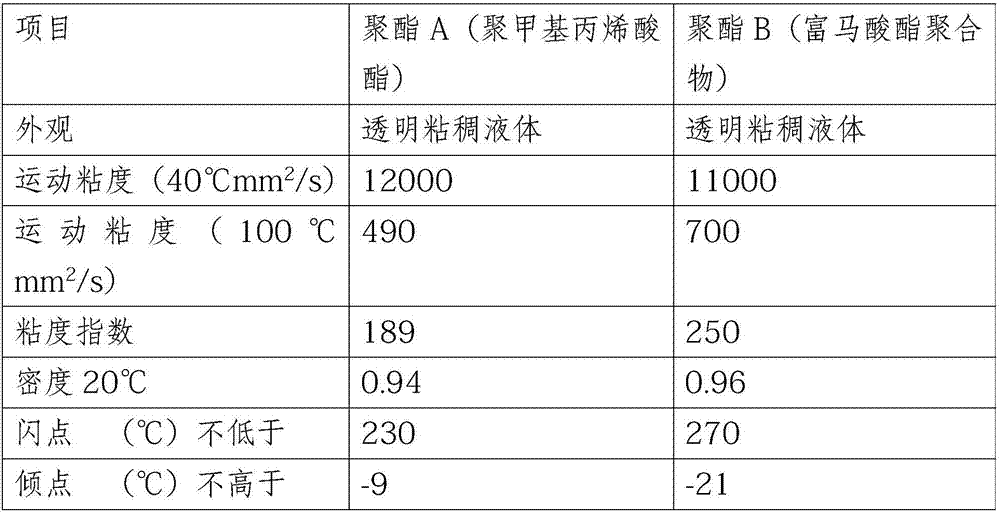

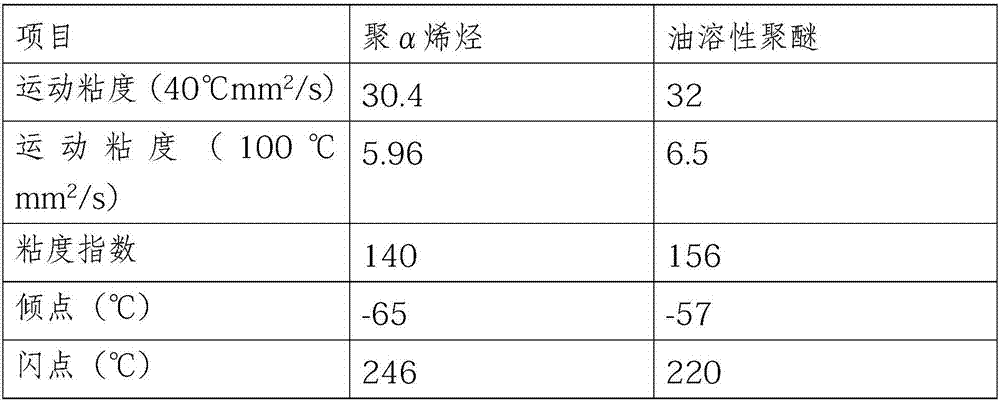

Embodiment 1

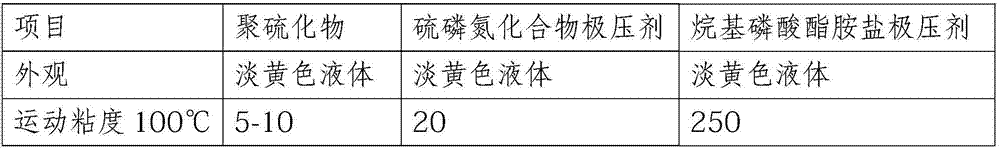

[0077] In a dry and clean reactor, add 2 / 3 mixed base oil, heat up to 60°C, add 1% polysulfide extreme pressure agent, 1% sulfur phosphorus nitrogen compound extreme pressure agent, 0.15% alkyl phosphate Amine salt, 0.1% organic tungsten extreme pressure agent, 2.0% PTFE emulsion friction reducer, 0.2% phenolic antioxidant and 0.2% amine antioxidant, 3.8% dispersant, 0.5% Benzotriazole derivative metal deactivator, stirring for 30 minutes, then adding 0.05% polyether anti-emulsion agent and stirring for 30 minutes, then adding the remaining 1 / 3 base oil, wherein the total mass percentage of mixed base oil is 91%, Cool down to 35°C and filter through a filter to obtain the product.

Embodiment 2

[0079] In a dry and clean reactor, add 2 / 3 mixed base oil 2, heat up to 60°C, add 0.75% polysulfide extreme pressure agent, 1.75% sulfur phosphorus nitrogen compound extreme pressure agent, 0.2% alkyl phosphate Amine salt, 0.15% organic tungsten extreme pressure agent, 1.5% PTFE emulsion friction reducer, 0.2% phenolic antioxidant and 0.2% amine antioxidant, 3.7% dispersant, 0.5% Benzotriazole derivative metal deactivator, stirring for 30 minutes, then adding 0.05% polyether anti-emulsion agent and stirring for 30 minutes, then adding the remaining 1 / 3 base oil, wherein the total mass percentage of mixed base oil is 91%, Cool down to 35°C and filter through a filter to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com