Continuous casting steel plate for porcelain enameling excellent in formability, resistance to occurrence of bubble or black point, and adhesion with porcelain enamel

A formability, anti-foaming technology, applied in the direction of manufacturing tools, furnace types, metal rolling, etc., can solve the problems of black spot resistance and low foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The best solution for implementing the present invention

[0033] A detailed description of the present invention is given here.

[0034] First, the chemical composition of the steel was analyzed in detail.

[0035] It has been known for a long time that the lower the C content in steel sheets, the better the formability. In order to obtain an aging index below 5 MPa and an r-value > 2.0 in the present invention, a C content of ≤ 0.002% is necessary. Preferably C≤0.0015%. Although it is not necessary to indicate the lower limit of C, the actual lower limit is 0.0005%, because further reducing the C content will increase the manufacturing cost.

[0036] Si content must be controlled at not more than 0.01%, because Si is detrimental to the performance of enamel. In order to obtain good enamel properties, the preferred Si content range is ≤0.005%.

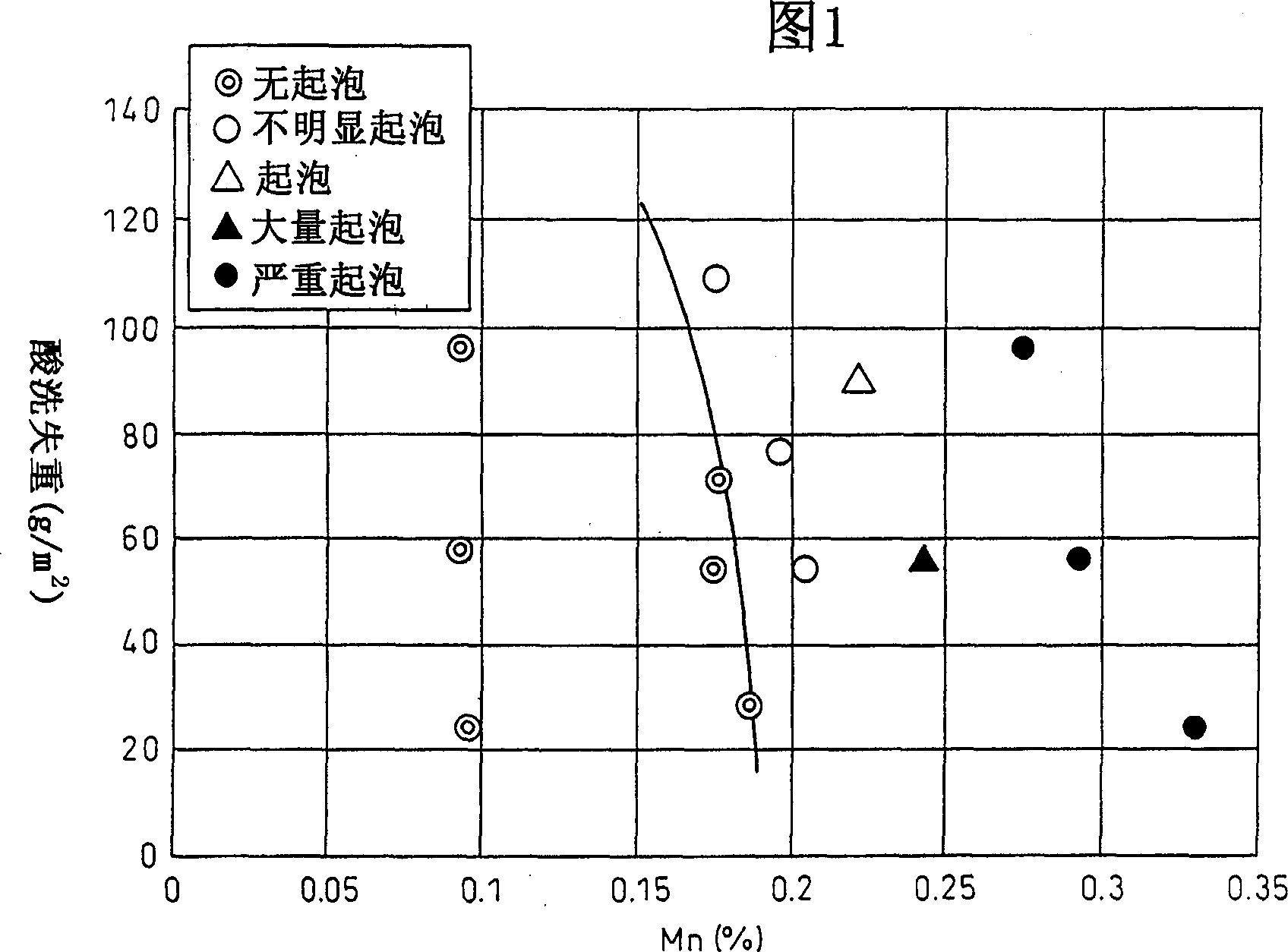

[0037] Mn is an important element affecting the performance of enamel when it is added together with O, V, and Nb. Mn c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com