Method and device for testing foam properties

A testing method and testing device technology, which is applied in the field of testing devices and foam performance testing, can solve the problems that the processing fluid cannot be effectively compared and tested, cannot adapt, and is easy to introduce errors, etc., to eliminate after-sales service factors, improve brand image, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

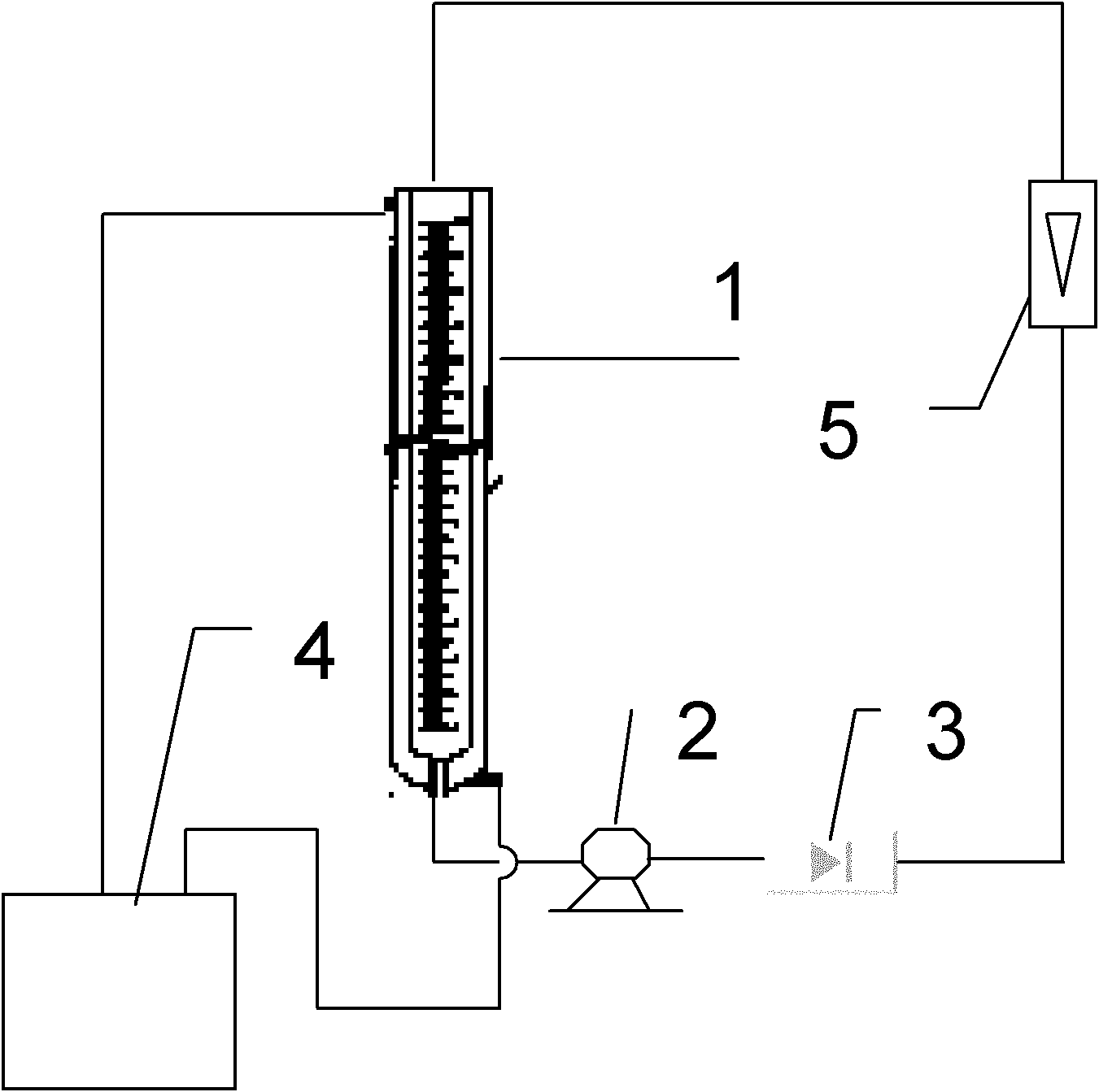

Method used

Image

Examples

Example

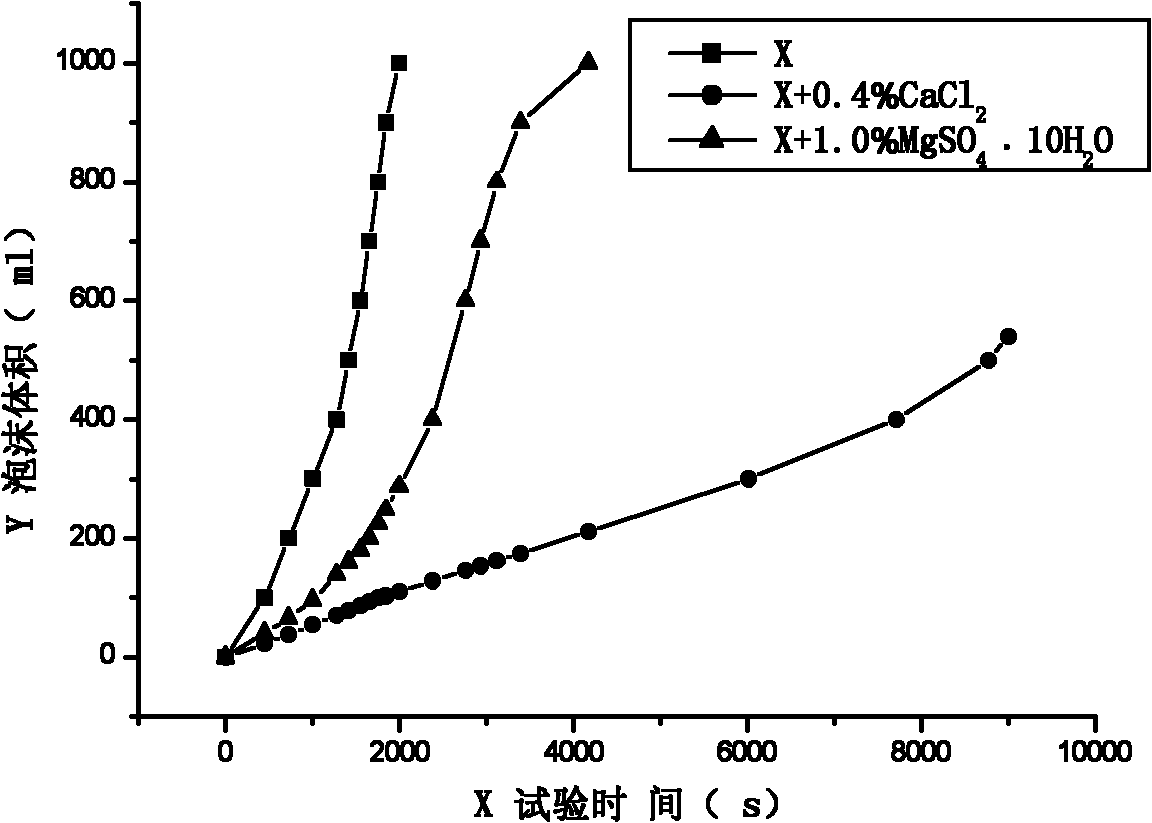

[0046] Comparative experiment example

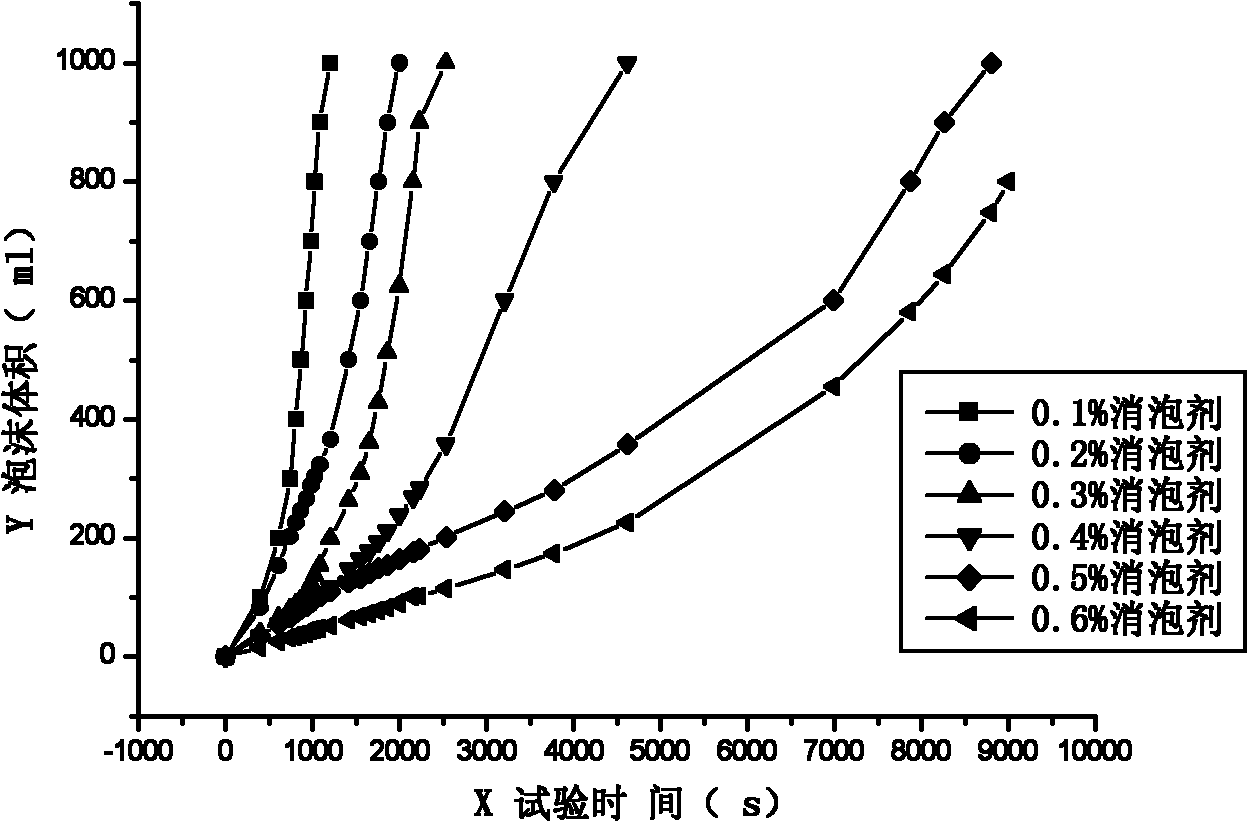

[0047] 1. The same emulsification system with different addition amount of defoamer

[0048] In the same emulsification system, the same defoaming agent (siloxane type) is added, but the addition amount is different. The defoaming property is tested by the manual power method and the method of the present invention.

[0049] 1.1. The defoaming property was tested by the manual power method, and the results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com