Air compressor oil composition and preparation method thereof

A technology of air compressor oil and composition, which is applied in the field of screw air compressor coolant and clean lubricating oil composition, which can solve the problems of poor cooling effect, achieve high use efficiency, ensure normal operation, and high temperature thermal oxidation Good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

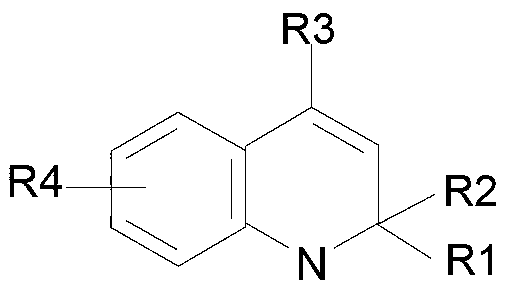

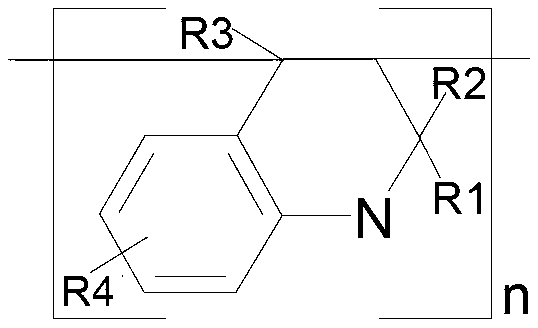

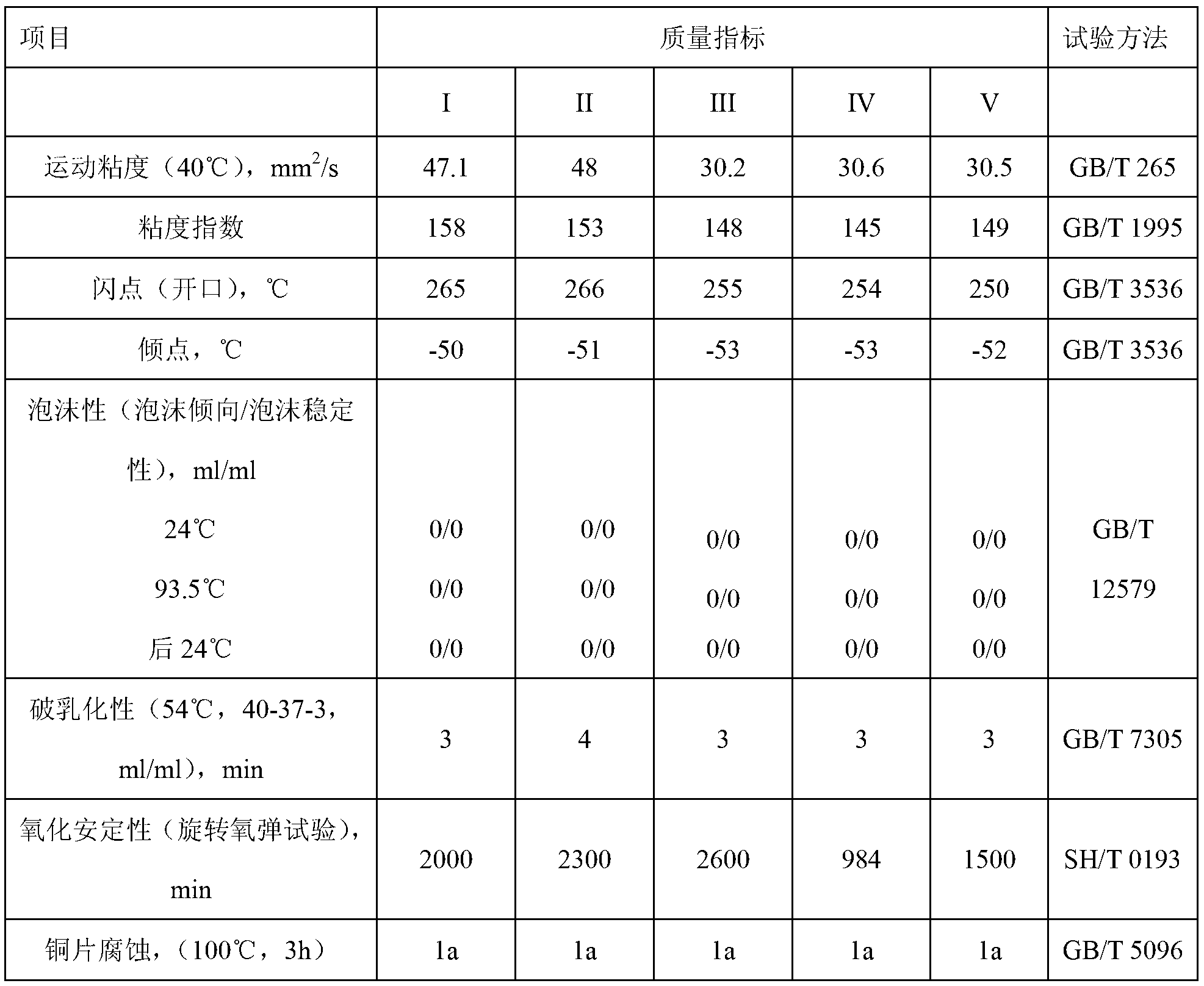

[0060] A high anti-oxidation clean type air compressor oil composition, its preparation method is: respectively take 95g oil-soluble polyether OSP-46 (Dow Chemical Company, the same below), 5g C8 / C10 saturated polyol ester Priolube3970 (Croda Chemical Company, the same below), 1.8g of Naugalube TMQ (2,2,4-trimethyl-1,2-dihydroquinoline antioxidant, Uniroyal Chemical Company, Inc., the same below), 0.04g of thiadi Azole derivative T561 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 0.003g methyl silicone oil T901 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 0.003g demulsifier propylene oxide / ethylene oxide embedded segment copolymer 5957 (Lubrizol Petroleum Chemical Company, the same below), put into a 200ml beaker and mix, and stir until uniform and transparent at 50°C to obtain Product I.

Embodiment 2

[0062] A high anti-oxidation clean air compressor oil composition, its preparation method is: respectively take 100g of oil-soluble polyether OSP-46, 0.8g of Naugalube TMQ, 0.1g of thiadiazole derivatives T561, 0.003g of T901 , 0.005g demulsifier 5957, mixed in a 200ml beaker, stirred at 20°C until uniform and transparent to obtain product II.

Embodiment 3

[0064] A high anti-oxidation clean type air compressor oil composition, its preparation method is: respectively take 90g oil-soluble polyether OSP-32 (Dow Chemical Company, the same below), 10g Priolube3970, 0.6g Naugalube TMQ, 0.1g Naugalube TMQ Benzotriazole derivatives T551 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 0.003g T901, 0.003g 5957 demulsifier, mixed in a 200ml beaker, stirred at 50°C until uniform and transparent, and sample III was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com