Emulsion for modifying water emulsion asphalt coating, preparation method of emulsion and coating

An asphalt coating and water-emulsion technology, applied in asphalt coatings, coatings, etc., can solve the problems that water-emulsion asphalt coatings cannot have high tensile strength, high elongation and high bond strength at the same time, so as to improve compatibility properties, improve tensile strength, and improve air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

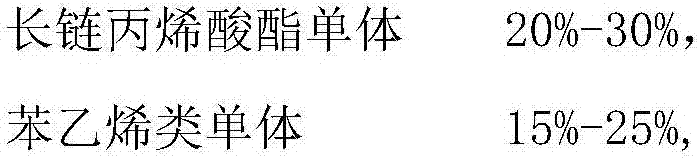

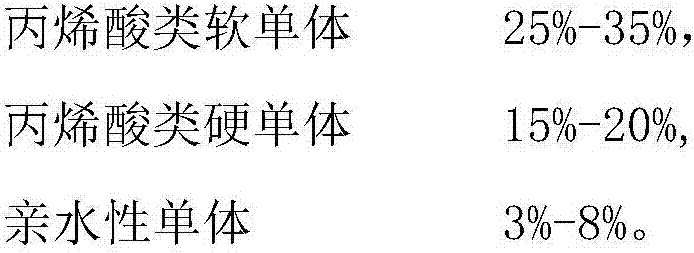

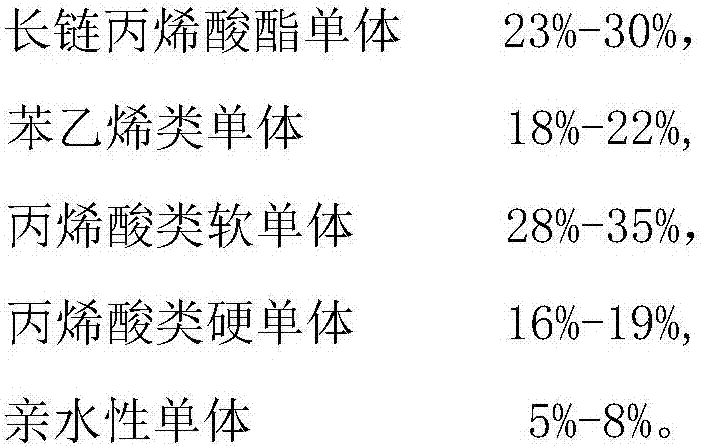

Method used

Image

Examples

Embodiment 1

[0031] Prepare 110g of octadecyl acrylate, 132g of styrene, 182g of butyl acrylate, 99g of methyl methacrylate, and 27.5g of methacrylic acid, and add the above monomers into a container and mix them evenly to obtain a mixed monomer;

[0032] Add 200g of deionized water weighed into the pre-emulsification tank, then add 5g of HYPERMER2296 emulsifier produced by Croda in the United Kingdom, add the above-mentioned mixed monomers under the condition of slow stirring, and pass the homogenization after all the above-mentioned mixed monomers are added. The device obtains the pre-emulsion;

[0033] The prepared 40g of deionized water was added to 3g of ammonium persulfate, stirred and dissolved to obtain ammonium persulfate solution;

[0034] Add the prepared 300g deionized water into the reaction flask, raise the temperature of the water to 80°C, then add 20g of ammonium persulfate solution to the reaction flask, and start adding the above pre-emulsion solution dropwise after keepi...

Embodiment 2

[0037] Prepare 165g of isocylacrylate, 104.5g of p-methylstyrene, 143g of isooctyl acrylate, 110g of methyl acrylate and 27.5g of acrylamide, add the above monomers into a container and mix them evenly to obtain a mixed monomer;

[0038] Add 200g of deionized water weighed into the pre-emulsification tank, then add 5g of HYPERMER2296 emulsifier produced by Croda in the United Kingdom, add the above-mentioned mixed monomers under the condition of slow stirring, and pass the homogenization after all the above-mentioned mixed monomers are added. The device obtains the pre-emulsion;

[0039] The prepared 40g of deionized water was added to 3g of ammonium persulfate, stirred and dissolved to obtain ammonium persulfate solution;

[0040] Add the prepared 300g deionized water into the reaction flask, raise the temperature of the water to 85°C, then add 20g of ammonium persulfate solution to the reaction flask, and start adding the above pre-emulsion solution dropwise after keeping th...

Embodiment 3

[0043] Prepare 137.5g lauryl acrylate, 115.5g p-methylstyrene, 176g butyl acrylate, 99g methyl methacrylate, 10g acrylamide, 12g acrylonitrile, mix the above monomers uniformly to obtain mixed monomer A, Add the above monomers into the container and mix evenly to obtain mixed monomers;

[0044] Add 200g of deionized water weighed into the pre-emulsification tank, then add 5g of HYPERMER2296 emulsifier produced by Croda in the United Kingdom, add the above-mentioned mixed monomers under the condition of slow stirring, and pass the homogenization after all the above-mentioned mixed monomers are added. The device obtains the pre-emulsion;

[0045] The prepared 40g of deionized water was added to 3g of ammonium persulfate, stirred and dissolved to obtain ammonium persulfate solution;

[0046] Add the prepared 300g deionized water into the reaction flask, raise the temperature of the water to 88°C, then add 20g of ammonium persulfate solution to the reaction flask, and start addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com