Resource recycling application of heavy metals in wastewater

A technology of heavy metal ions and recovery agents, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as waste of precious resources, endangering human health, and endangering health, and achieves a good positioning effect, easily reverted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

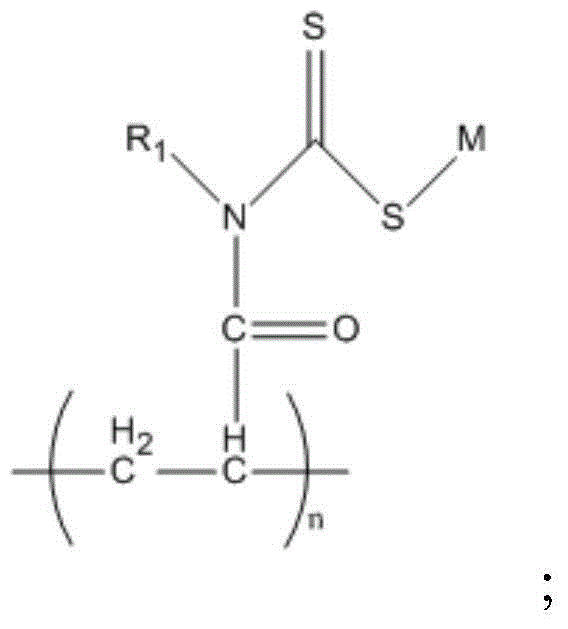

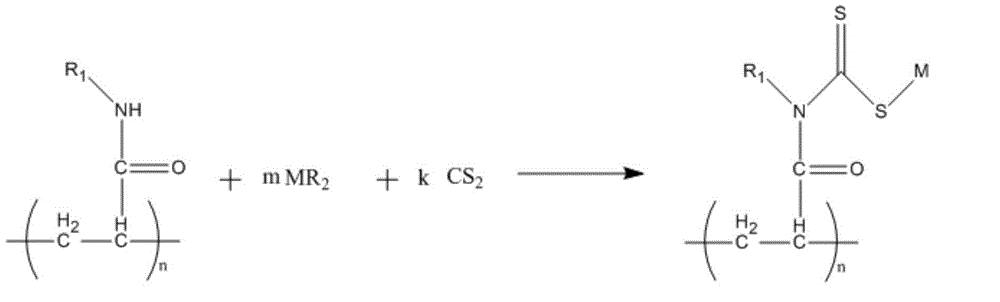

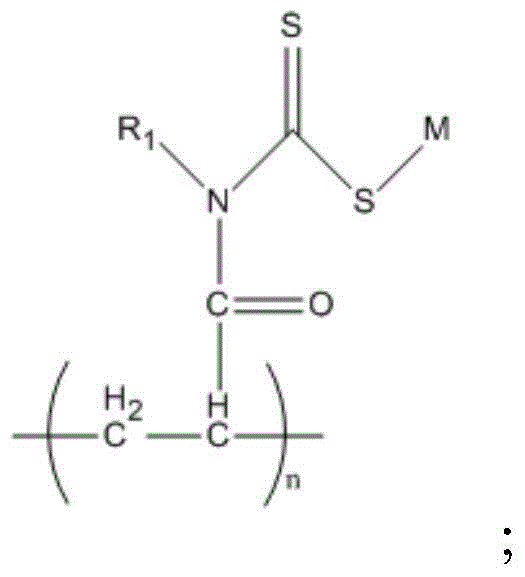

Method used

Image

Examples

Embodiment 1

[0041] Dissolve 360g of polyacrylamide in 300g of deionized water, add 270g of sodium methoxide solution dissolved in 100g of deionized water, mix and stir, then slowly add 380g of carbon disulfide, mix and stir, control the temperature not higher than 80°C and stir until the reaction temperature and room temperature When corresponding, stop stirring, that is a heavy metal ion recovering agent. (approximately equal to polyacrylamide monomer: Na + : CS 2 The molar ratio is 1:1:1)

[0042] The heavy metal ion recovery agent prepared above is directly mixed and stirred with the waste water whose type and content of heavy metals have been confirmed by analysis. After the heavy metal ions are tested to meet the standard, the waste water can be discharged, and the precipitates that have absorbed heavy metal ions are collected for resource recycling.

[0043] The above-mentioned precipitate that has absorbed heavy metal ions is prepared into a suspension, and lithium aluminum tetra...

Embodiment 2

[0045] Dissolve 366g of polyacrylamide in 400g of deionized water, add 200g of sodium hydroxide solution dissolved in 400g of deionized water, mix and stir, then slowly add 380g of carbon disulfide, mix and stir, control the temperature not higher than 80°C and stir until the reaction temperature is equal to When the room temperature is equal, stop stirring, it is a heavy metal ion recovery agent. (approximately equal to polyacrylamide monomer: Na + : CS 2 The molar ratio is 1:1:1)

[0046] The main heavy metals in a metallurgical wastewater are: Cd, Co, Cu, Ni, Pb. The pH value of the waste water is 2.5. After the impurities in the waste water are precipitated, the supernatant is analyzed and measured for the concentration of heavy metals. After adding 10 g / L of the heavy metal ion recovery agent prepared above and stirring for 5 minutes, the heavy metal concentration is detected after filtering the flocculent precipitate. As shown in the following table:

[0047] ...

Embodiment 3

[0051] Dissolve 780g of polyacrylamide in 400g of deionized water, add 224g of potassium hydroxide solution dissolved in 560g of deionized water, mix and stir, then slowly add 380g of carbon disulfide, mix and stir, control the temperature not higher than 80°C and stir until the reaction temperature is equal to When the room temperature is equal, stop stirring, it is a heavy metal ion recovery agent. (approximately equal to polyacrylamide monomer: K + : CS 2 The molar ratio is 2:0.8:1)

[0052]The heavy metal ion recovery agent prepared above is directly mixed and stirred with the waste water whose type and content of heavy metals have been confirmed by analysis. After the heavy metal ions are tested to meet the standard, the waste water can be discharged, and the precipitates that have absorbed heavy metal ions are collected for resource recycling.

[0053] The above-mentioned precipitate that has absorbed heavy metal ions is prepared into a suspension, and nanometer zero-v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com