High-temperature oil-soluble temporary plugging agent and preparation method thereof

A technology of temporary plugging agent and high temperature oil, applied in chemical instruments and methods, drilling composition and other directions, can solve problems such as high temperature resistance, achieve the effect of protecting high temperature oil layer, solving high temperature resistance and good oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Select raw materials by weight percentage

[0026] Asphalt: 30%

[0027] C9 petroleum resin: 30%

[0028] Coumarone resin: 25%

[0029] Surfactant: 5%%

[0031] Softening point additive: 8%.

[0032] Wherein, the above-mentioned surfactant is polyoxyethyl alkylphenyl ether, the polymer fiber is polyvinyl alcohol fiber, and the softening point additive is cationic starch.

[0033] The preparation method is as follows:

[0034] (1) Put the asphalt into the reaction kettle, heat and melt it, add a certain quality of C9 petroleum resin and coumarone resin, and continue to stir until it is completely melted;

[0035] (2) Add a certain quality of surfactants, polymer fibers, and softening point additives into the reaction kettle, stir for 30 minutes, mix well, stop heating, collect the particles after cooling, wash with water, and sieve to obtain oils with different particle sizes Soluble temporary plugging agent.

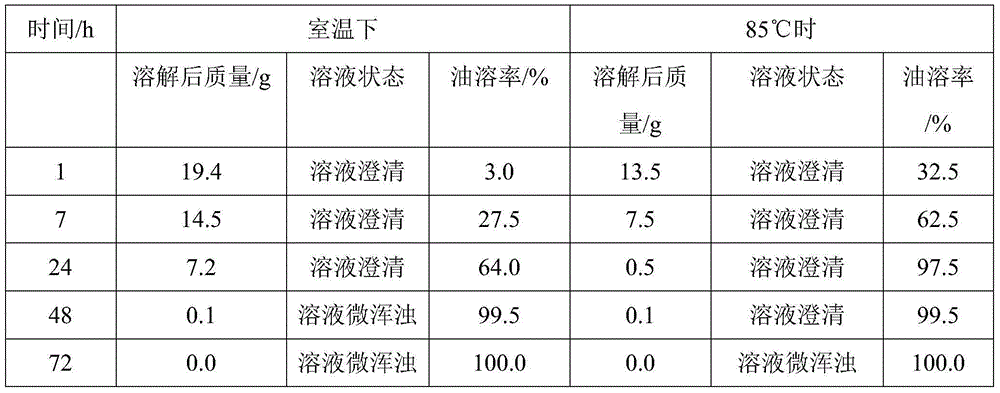

[0036] Determination of ...

Embodiment 2

[0051] Select raw materials by weight percentage

[0052] Bitumen: 20%

[0053] C9 petroleum resin: 30%

[0054] Coumarone resin: 30%

[0055] Surfactant: 10%

[0056] Polymer fiber: 5%

[0057] Softening point additive: 5%.

[0058] Wherein, the above-mentioned surfactant is dodecyltrimethylammonium chloride, the polymer fiber is polyurethane fiber, and the softening point additive is lignite.

[0059] The preparation method is as follows:

[0060] (1) Put the asphalt into the reaction kettle, heat and melt it, add a certain quality of C9 petroleum resin and coumarone resin, and continue to stir until it is completely melted;

[0061] (2) Add a certain quality of surfactants, polymer fibers, and softening point additives into the reaction kettle, stir for 30 minutes, mix well, stop heating, collect the particles after cooling, wash with water, and sieve to obtain oils with different particle sizes Soluble temporary plugging agent.

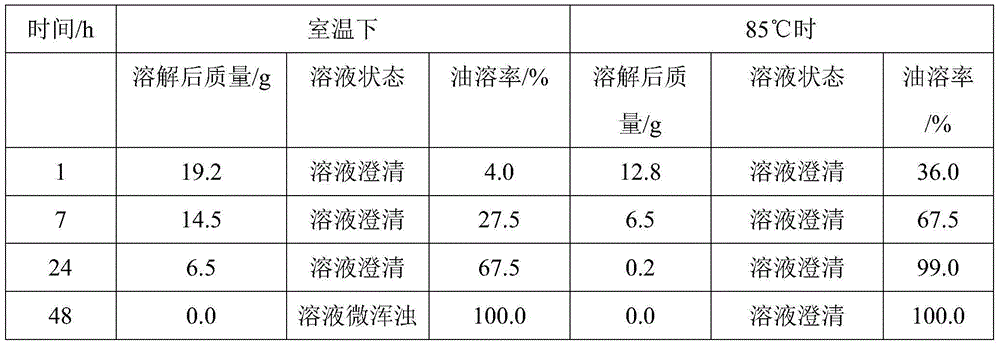

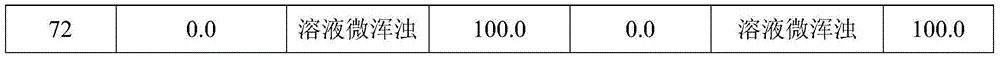

[0062] Determination of oil solubil...

Embodiment 3

[0077] Select raw materials by weight percentage

[0078] Bitumen: 20%

[0079] C9 petroleum resin: 20%

[0080] Coumarone resin: 50%

[0081] Surfactant: 5%

[0082] Polymer fiber: 2%

[0083] Softening point additive: 3%.

[0084] Wherein, the above-mentioned surfactant is polyoxyethyl alkyl ether, the polymer fiber is modified polyester fiber, and the softening point additive is lignite.

[0085] The preparation method is as follows:

[0086] (1) Put the asphalt into the reaction kettle, heat and melt it, add a certain quality of C9 petroleum resin and coumarone resin, and continue to stir until it is completely melted;

[0087] (2) Add a certain quality of surfactants, polymer fibers, and softening point additives into the reaction kettle, stir for 30 minutes, mix well, stop heating, collect the particles after cooling, wash with water, and sieve to obtain oils with different particle sizes Soluble temporary plugging agent.

[0088] A core simulation test was carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com