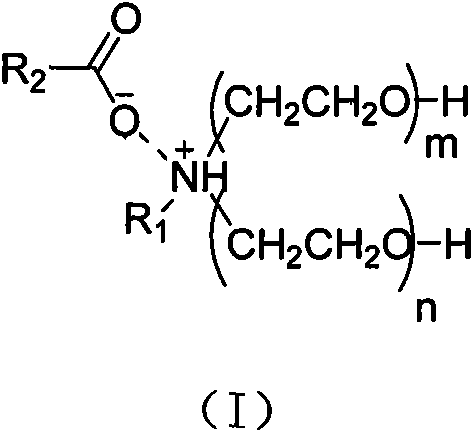

White carbon black dispersant, preparation method and applications

A technology of white carbon black and dispersant, which is applied to the preparation of mercaptans, the preparation of carboxylate, chemical instruments and methods, etc., can solve the problems of difficulty in dispersion, loss of zinc salt and zinc, poor rubber compatibility, etc., and achieves simple process, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

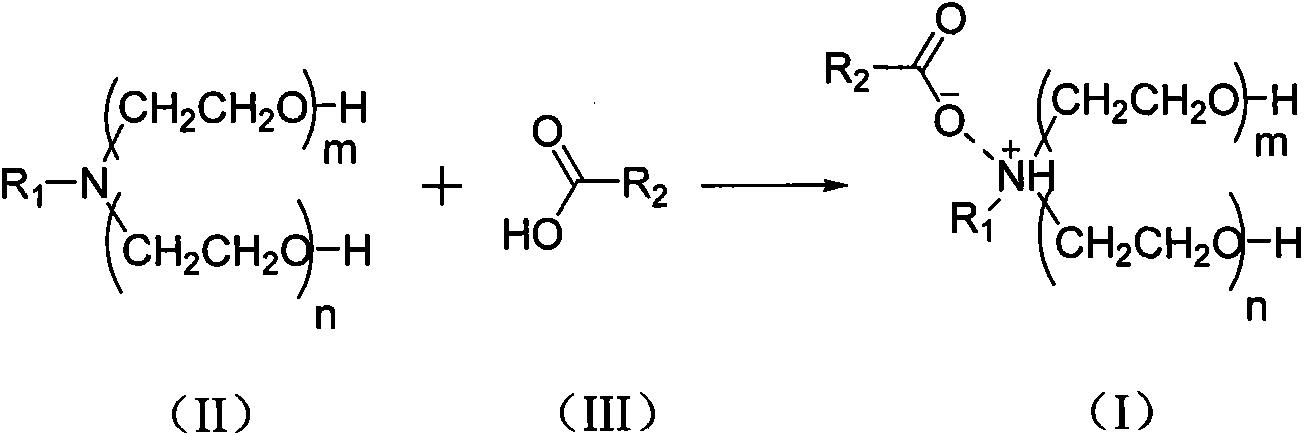

Method used

Image

Examples

Embodiment 1

[0038] In a 500ml round bottom flask equipped with a stirrer, a thermometer, and a reflux condenser, add 0.1 mol of octadecylamine polyoxyethylene ether with a sum of 60 ethoxy groups of m+n and 0.15 mol of palmitic acid, and heat to 80 Make it all melted at ℃, add 50ml ethanol, then react under reflux until the solution is clear and transparent, change the distillation status to remove the solvent, and cool to below 60℃ to obtain the product.

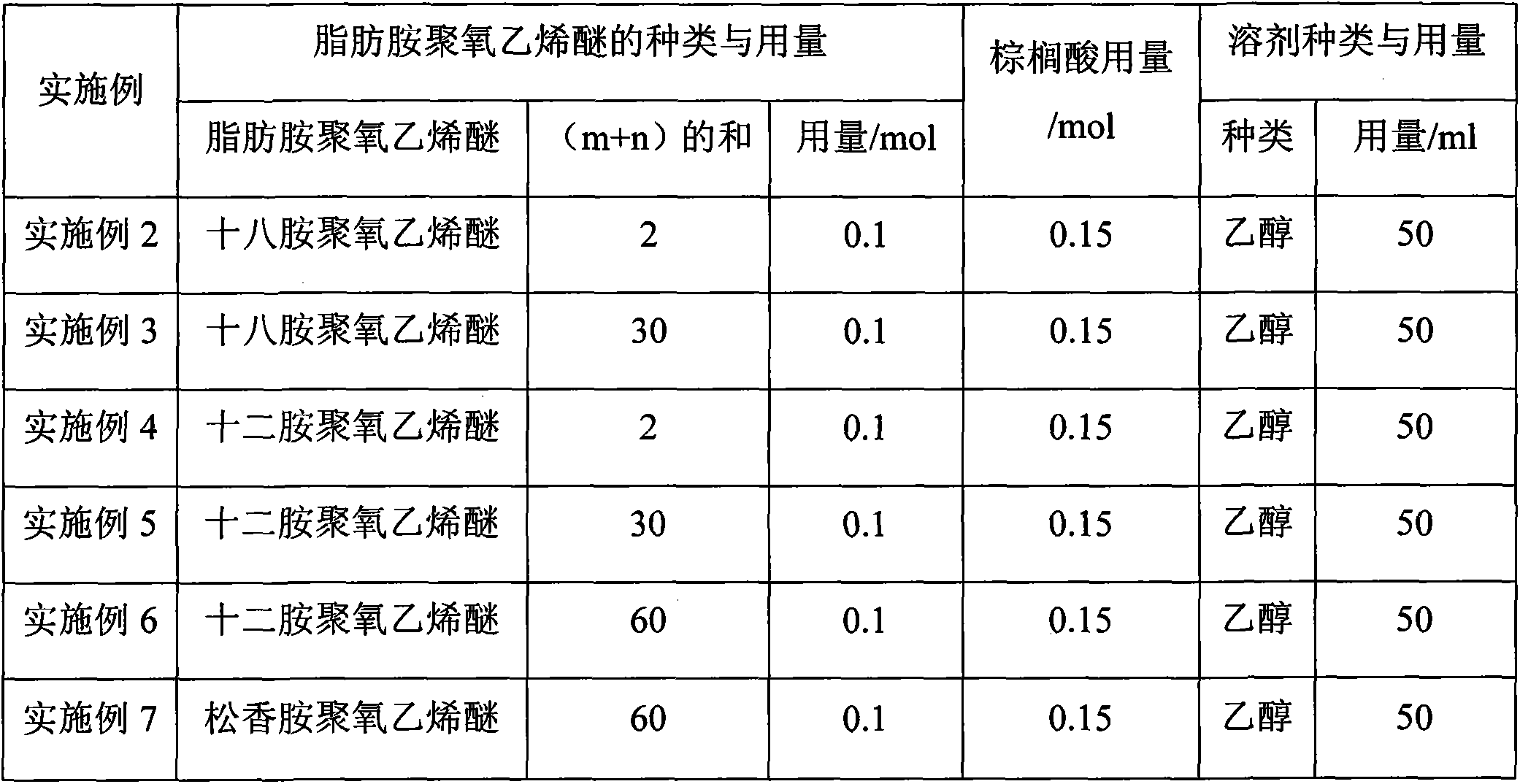

Embodiment 2~7

[0040] Except for changing the type of fatty amine polyoxyethylene ether, the preparation process of the white carbon black dispersant in Example 1 was repeated. For specific data, see Table 1 below.

[0041] Table 1 Raw materials and products used in Examples 2-7

[0042]

Embodiment 8

[0044] Add 0.2 mol of dodecylamine polyoxyethylene ether with the number of ethoxy groups of m+n and 60, and 0.15 mol of oleic acid into a 500ml round bottom flask reactor equipped with a stirrer, a thermometer and a reflux condenser. The whole is melted at 100°C, 50ml of toluene is added, and then the solution is reacted under reflux until the solution is clear and transparent. The solvent is changed to the distillation state and cooled to below 80°C to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com