Preparation method of transparent dealcoholized vulcanizing silicone rubber by quickly curing single components at room temperature

A vulcanized silicone rubber, fast curing technology, applied in the field of preparation of dealcoholized one-component room temperature vulcanized silicone rubber, can solve the problem that the curing speed of silicone rubber does not have fast curing, etc., achieve excellent storage effect, fast vulcanization speed, touch good denaturation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

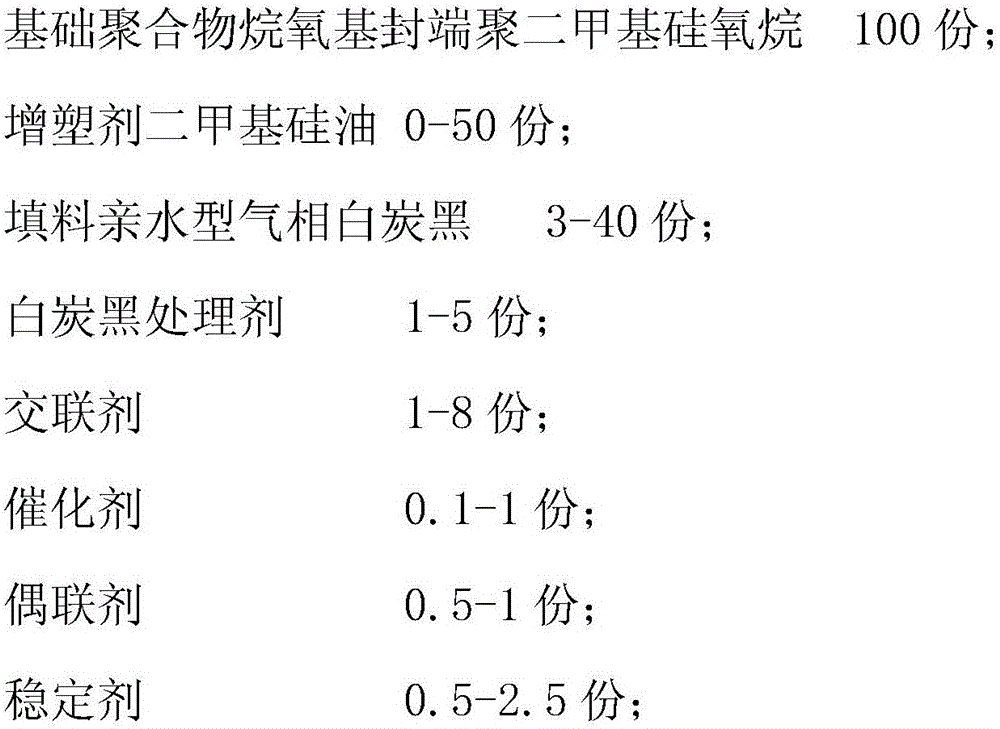

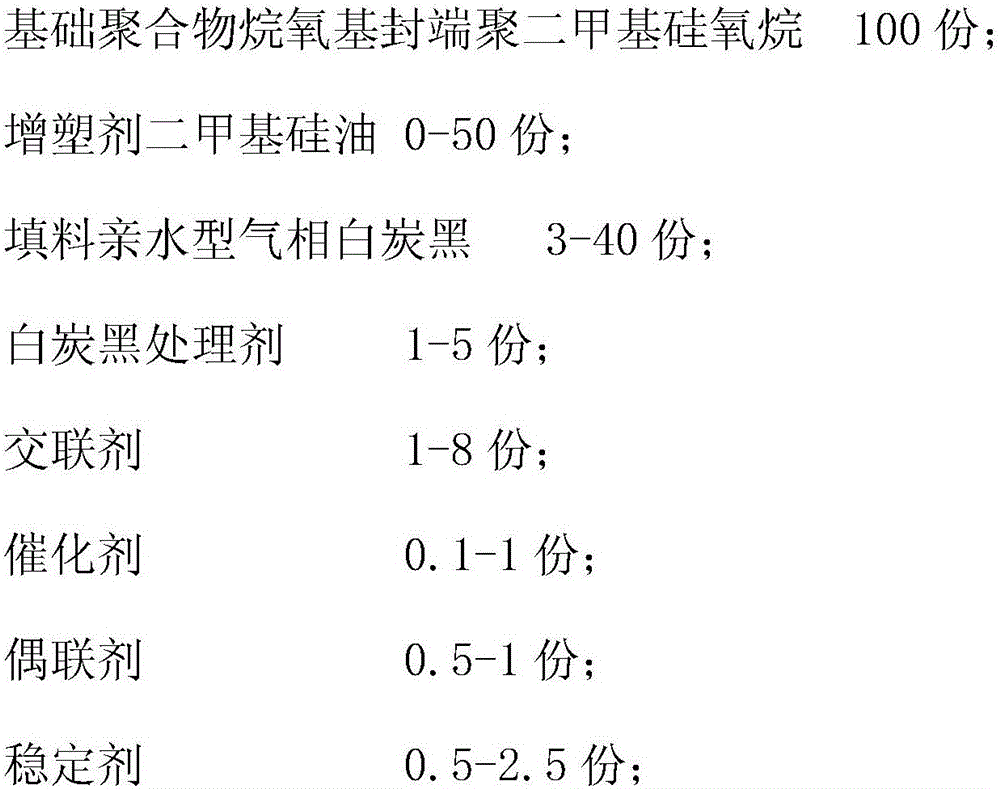

Method used

Image

Examples

Embodiment 1

[0025] Under the protection of nitrogen, 100 parts of 20000mPa.s alkoxy-terminated polydimethylsiloxane, 30 parts of plasticizer dimethyl silicone oil and 2 parts of hexamethyldisilazane were mixed with a planetary mixer at 25°C After mixing for 30 minutes, add 18 parts of filler hydrophilic type 150㎡ / g fumed silica, after the dispersion is uniform, remove the low boilers in vacuum, then add 3 parts of methyltrimethoxysilane and 0.25 parts of dibutyltin dilaurate , 1 part of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 1.5 parts of hexamethyldisilazane, vacuum-0.097 to remove low boilers for 30min, move to extruder, press Filling, to obtain a one-component room temperature rapid curing transparent dealcoholized vulcanized silicone rubber.

Embodiment 2

[0031] Under the protection of nitrogen, 100 parts of alkoxy-terminated polydimethylsiloxane with a viscosity of 50000 mPa.s, 15 parts of plasticizer dimethyl silicone oil, and 3 parts of octamethylcyclotetrasilazane were prepared at 25 ° C. After mixing with a planetary mixer, add 18 parts of 200㎡ / g hydrophilic fumed silica. After the dispersion is even, remove the low boilers in a vacuum, and then add 6 parts of methyltripropoxysilane and 0.5 parts of dibutyltin dilaurate in sequence. , 0.8 parts of γ-(2,3-epoxy, propoxy)propyltrimethoxysilane, 1.5 parts of hexamethylcyclotrisilazane, vacuum-0.092Mpa to remove low boilers for 30min, and move to the extruder , pressed out and filled to obtain a one-component room temperature fast-curing transparent dealcoholized vulcanized silicone rubber.

Embodiment 3

[0037] Under the protection of nitrogen, 100 parts of alkoxy-terminated polydimethylsiloxane with a viscosity of 80000mPa.s, 25 parts of plasticizer dimethyl silicone oil and 4 parts of hexamethyldisilazane were used at 25°C After mixing with planetary mixer, add 22 parts of 200㎡ / g hydrophilic fumed silica. After dispersing evenly, remove the low boilers in vacuum, then add 8 parts of vinyltrimethoxysilane, 0.7 parts of dibutyltin dilaurate, N -1 part of (β-aminoethyl)-γ-aminopropyltrimethoxysilane, 2 parts of hexamethylcyclotrisilazane, vacuum-0.095Mpa to remove low boilers for 30min, move to extruder, press Filling, to obtain a one-component room temperature rapid curing transparent dealcoholized vulcanized silicone rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com