Silicone rubber insulation material applied to high voltage cable accessories in European series and preparation method for material

A medium and high voltage cable and silicone rubber insulation technology, which is applied in the direction of rubber insulators and organic insulators, can solve problems such as low electrical performance, odor of products, and reduced breakdown voltage strength of insulating rubber, and achieve low product defect rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

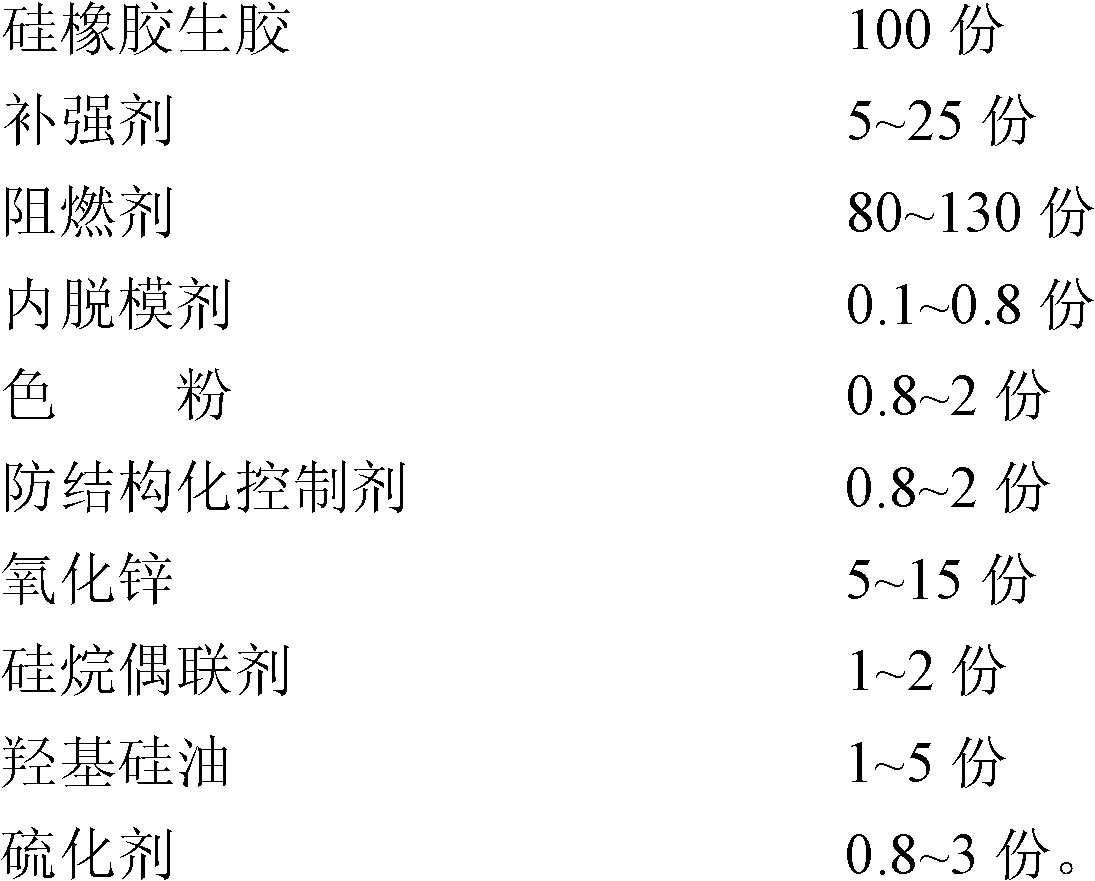

[0036] A silicone rubber insulating rubber compound used in European series medium and high voltage cable accessories. The components of the insulating rubber compound are as follows, all in parts by mass:

[0037]

[0038]

[0039] A kind of preparation method for the silicone rubber insulating compound of European type series medium and high voltage cable accessories as mentioned above, comprises the following steps:

[0040] 1) Feeding

[0041] Start the kneader, after heating up to 140°C, add 100 parts of methyl vinyl silicone rubber raw rubber by mass fraction, 0.3 parts of polytetrafluoroethylene powder prefabricated release agent, 0.8 parts of general furnace black N660, indirect 8 parts of Zinc Oxide in closed kneading chamber; after 5 minutes, when the temperature rises to 135°C, quickly add 60 parts of aluminum hydroxide and 12.5 parts of fumed white carbon black; Add 60 parts of aluminum hydroxide, 12.5 parts of fumed white carbon black, 1.2 parts of vinyl tr...

Embodiment 2

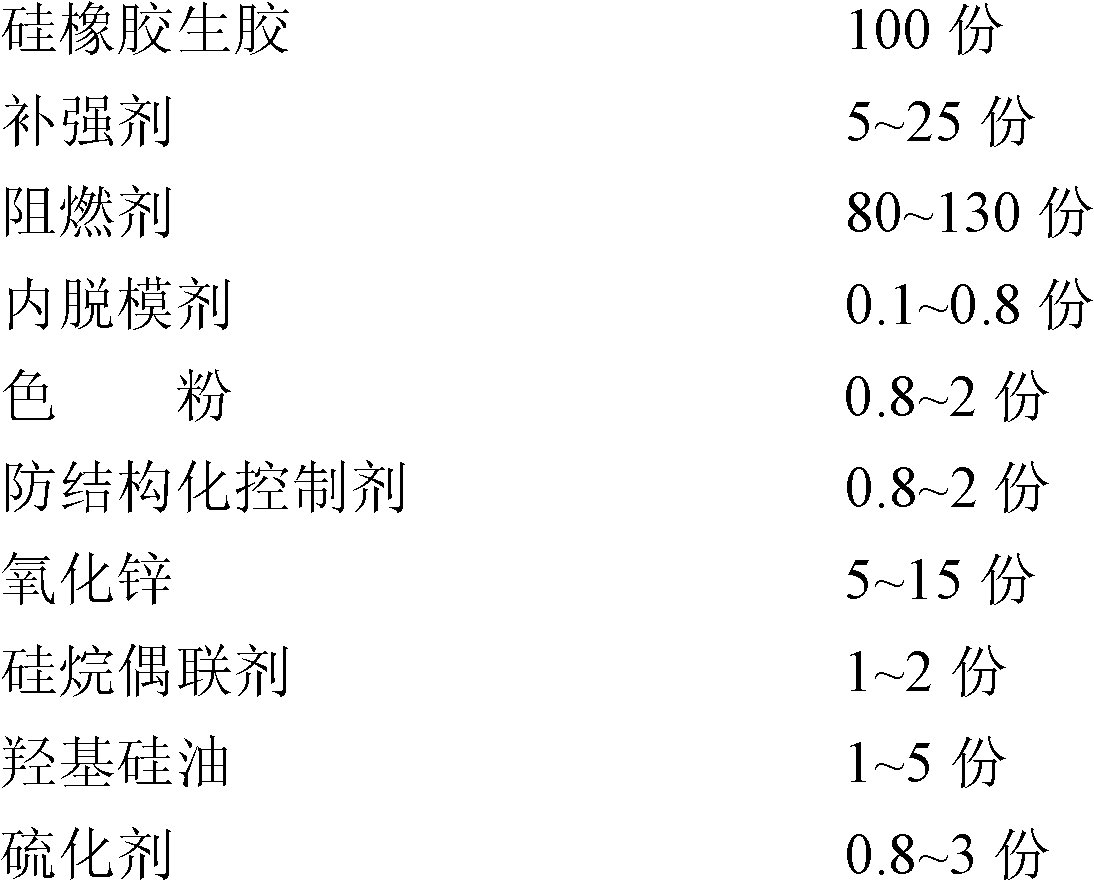

[0049] A silicone rubber insulating rubber compound used in European series medium and high voltage cable accessories. The components of the insulating rubber compound are as follows, all in parts by mass:

[0050]

[0051]

[0052] A kind of preparation method for the silicone rubber insulating compound of European type series medium and high voltage cable accessories as mentioned above, comprises the following steps:

[0053] 1) Feeding

[0054] Start the kneader, heat up to 140°C, add 100 parts of methyl vinyl silicone rubber raw rubber by mass fraction, 0.3 parts of polytetrafluoroethylene powder prefabricated release agent, 0.8 parts of general furnace black N660, indirect method 5 parts of zinc oxide; kneading in a closed kneading chamber. After 8 minutes, when the temperature rises to 140°C, quickly add 65 parts of aluminum hydroxide and 10 parts of fumed silica; 65 parts of aluminum hydroxide, 10 parts of fumed silica, 1.5 parts of vinyl tris(β-methoxyethoxy) si...

Embodiment 3

[0062] A silicone rubber insulating rubber compound used in European series medium and high voltage cable accessories. The components of the insulating rubber compound are as follows, all in parts by mass:

[0063]

[0064]

[0065] A kind of preparation method for the silicone rubber insulating compound of European type series medium and high voltage cable accessories as mentioned above, comprises the following steps:

[0066] 1) Feeding

[0067] Start the kneader, heat up to 140°C, add 100 parts of methyl vinyl silicone rubber raw rubber by mass fraction, 0.1 part of polytetrafluoroethylene powder prefabricated release agent, 2 parts of general furnace black N6602, and indirect oxidation 15 parts of zinc; kneading in a closed kneading chamber. After 8 minutes, when the temperature rises to 140°C, quickly add 40 parts of aluminum hydroxide and 2.5 parts of fumed silica; close the kneading chamber and continue to heat up to 140°C, add hydrogen 40 parts of alumina, 2.5 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com