Double-component addition-type liquid silicone rubber as well as preparation method of same

A liquid silicone rubber, addition molding technology, applied in the coating and other directions, can solve the problems of poor adhesion of the addition silicone rubber, the peeling off of the silicone coating, etc., to achieve good compatibility and permeability, fast vulcanization speed, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

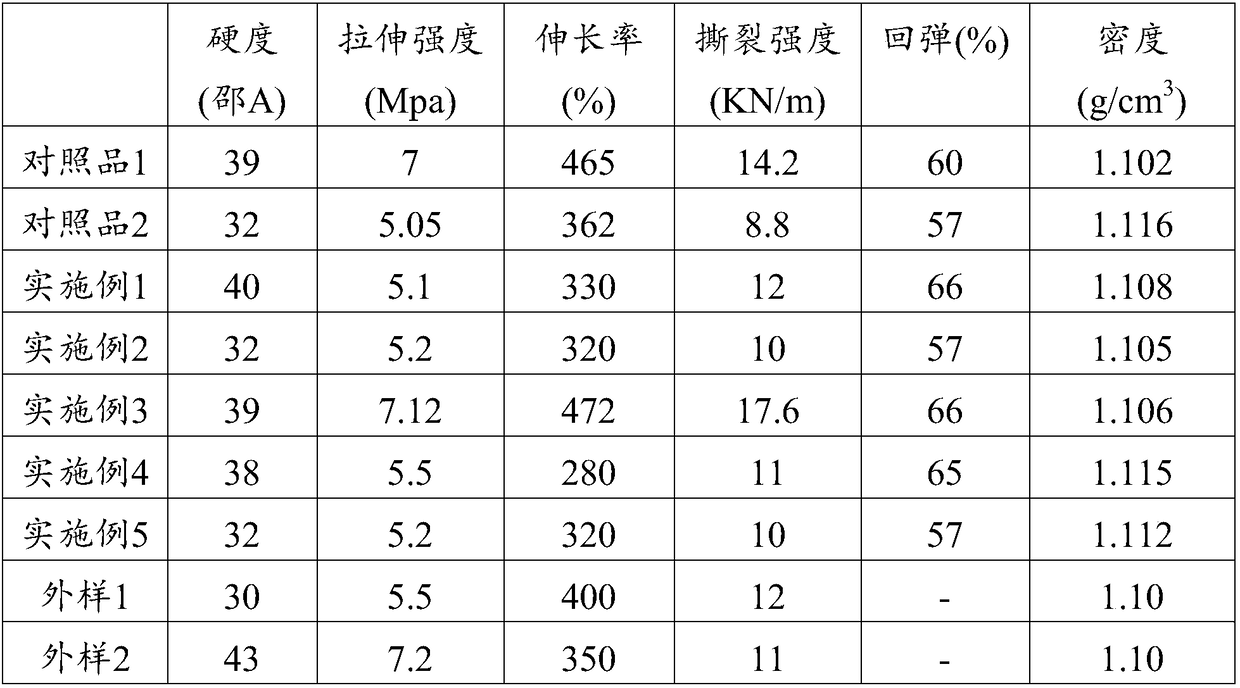

Examples

Embodiment 1

[0031] 1. Add 100 parts of vinyl-terminated silicone oil with a viscosity of 20000mpa.s and 5 parts of vinyl-terminated side-chain vinyl silicone oil with a viscosity of 1000mpa.s into the kneader and stir evenly, then mix 40 parts of 2 / g of fumed silica, 12 parts of silazane treatment agent and 3 parts of water were added to the kneader for 3 hours and stirred for 3 hours, then heated to 150°C for 2 hours, then vacuumed for 2 hours, discharged, and passed through three-roll grinding Machine, get base glue.

[0032] 2. Take 100 parts of base glue, add 8 parts of vinyl-terminated silicone oil with a viscosity of 20000mpa.s, 1 part of tackifier and 0.5 parts of platinum catalyst (vinyl chromium compound 2000ppm) and stir in a planetary mixer at 30rpm for 1h until uniform Get A component.

[0033] 3. Stir 60 parts of vinyl-terminated silicone oil with a viscosity of 5000mpa.s, 40 parts of hydrogen-containing silicone oil (0.5% hydrogen content) and 0.36 parts of inhibitor 1-eth...

Embodiment 2

[0038] 1. Add 100 parts of vinyl-terminated silicone oil with a viscosity of 10000mpa.s and 5 parts of vinyl-terminated side-chain vinyl silicone oil with a viscosity of 1000mpa.s into a kneader and stir evenly, and then mix 40 parts of a specific surface area of 300m 2 / g of fumed silica, 10 parts of silazane treatment agent, 2 parts of siloxane treatment agent and 3.5 parts of water were added to the kneader and stirred for 3 hours, then heated to 150 ° C for 2 hours, and then vacuumed for 2 hours. The material is discharged and passed through a three-roll mill to obtain the base rubber.

[0039] 2. Take 100 parts of base glue, add 8 parts of vinyl-terminated silicone oil with a viscosity of 10000mpa.s, 1 part of tackifier and 0.5 parts of platinum catalyst (vinyl chromium compound 2000ppm) and stir in a planetary mixer at 30rpm for 1h until uniform Get A component.

[0040] 3. Stir 20 parts of vinyl-terminated silicone oil with a viscosity of 2000mpa.s, 80 parts of hydro...

Embodiment 3

[0045]1. Add 100 parts of vinyl-terminated silicone oil with a viscosity of 20000mpa.s and 5 parts of vinyl-terminated side-chain vinyl silicone oil into the kneader, and then add 40 parts of 2 / g of fumed silica, 10 parts of silazane treatment agent, 4 parts of siloxane treatment agent and 3.5 parts of water were added to the kneader and stirred for 3 hours, then heated to 150 ° C for 2 hours, and then vacuumed for 2 hours. Pass through a three-roll mill to obtain base rubber.

[0046] 2. Take 100 parts of base glue, add 15 parts of vinyl-terminated silicone oil with a viscosity of 10000mpa.s, 1.5 parts of tackifier and 0.5 parts of platinum catalyst (vinyl chromium compound 2000ppm) and stir in a planetary mixer at 30rpm for 1h until uniform Get A component.

[0047] 3. Stir 70 parts of vinyl-terminated silicone oil with a viscosity of 2000mpa.s, 30 parts of hydrogen-containing silicone oil (0.8% hydrogen content) and 0.4 part of inhibitor 1-ethynyl cyclohexanol in a high-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com