Antiskid wear-resistant tire composition and preparation method thereof

A composition and tire technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of reduced tire service life, poor wet skid resistance, and high tread hardness, and achieve improved wear resistance, The effect of slowing down aging and improving tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw material components: 15 parts of silicone rubber, 16 parts of EPDM rubber, 5 parts of polyvinyl chloride, 4 parts of lead phosphite, 20 parts of hydrogenated nitrile rubber, 1 part of rubber vulcanizing agent, 14 parts of highly dispersed white carbon black, 3 parts of nano zinc oxide, 5 parts of coupling agent, 4 parts of tackifying resin, 1 part of accelerator NOBS, 0.5 parts of accelerator CZ, 3 parts of aromatic oil, 1.5 parts of anti-aging agent H.

[0020] making process:

[0021] The first step: put in the corresponding parts of the raw material components: silicone rubber, EPDM rubber, hydrogenated nitrile rubber, polyvinyl chloride, lead phosphite, anti-aging agent H and tackifying resin mixing for 5-10 minutes, The mixing temperature is 181-190°C, the pressure is 0.65-0.75Mpa, and the film is obtained by mixing;

[0022] The second step: cool the obtained film with a fan for 6 hours, and cool it naturally for 12 hours;

[0023] The third step: mix the co...

Embodiment 2

[0029] Raw material components: 14 parts of silicone rubber, 12 parts of EPDM rubber, 4 parts of polyvinyl chloride, 2 parts of lead phosphite, 16 parts of hydrogenated nitrile rubber, 1 part of rubber vulcanizing agent, 10 parts of highly dispersed white carbon black, 1 part of nano zinc oxide, 5 parts of coupling agent, 4 parts of tackifying resin, 1 part of accelerator NOBS, 0.5 parts of accelerator CZ, 2 parts of aromatic oil, 1.3 parts of anti-aging agent H.

[0030] The preparation method is the same as in Example 1.

Embodiment 3

[0032] Raw material components: 16 parts of silicone rubber, 18 parts of EPDM rubber, 8 parts of polyvinyl chloride, 5 parts of lead phosphite, 20 parts of hydrogenated nitrile rubber, 2 parts of rubber vulcanizing agent, 20 parts of highly dispersed white carbon black, 5 parts of nano-zinc oxide, 7 parts of coupling agent, 6 parts of tackifying resin, 2 parts of accelerator NOBS, 1 part of accelerator CZ, 5 parts of aromatic oil, and 2 parts of anti-aging agent H.

[0033] The preparation method is the same as in Example 1.

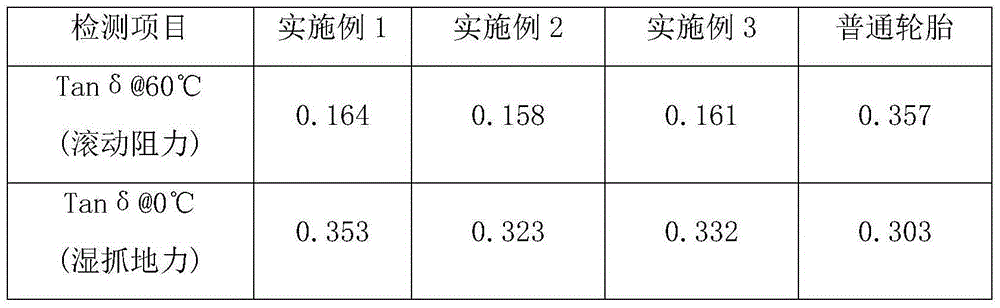

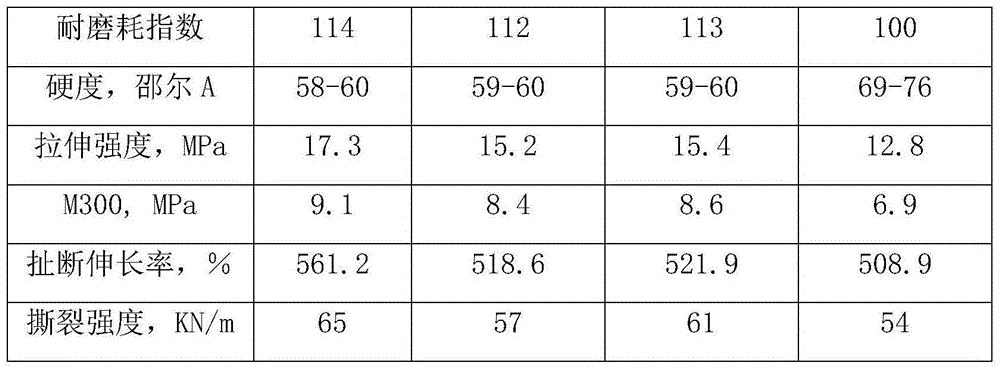

[0034] Adopt the main technical index in the tire of the rubber composition that embodiment 1-embodiment 3 makes and common tire comparative experiment:

[0035]

[0036]

[0037] The present invention carries out running test through the tire of the rubber composition that embodiment 1-embodiment 3 makes, and this tire is compared with common tire, runs on the glass surface that has water smoothly, and brake does not skid and does not "discharge"....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com