Special highly-wear-resistant rubber material used for tire tread

A technology for rubber materials and tire treads, which is applied in the field of high wear-resistant rubber materials for tire treads, which can solve the problems of wear resistance, strength and heat resistance, and cannot adapt to high-speed, overloaded, long-distance and other conditions of use. and other problems, to achieve the effect of improving elasticity, flex cracking resistance and mechanical properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

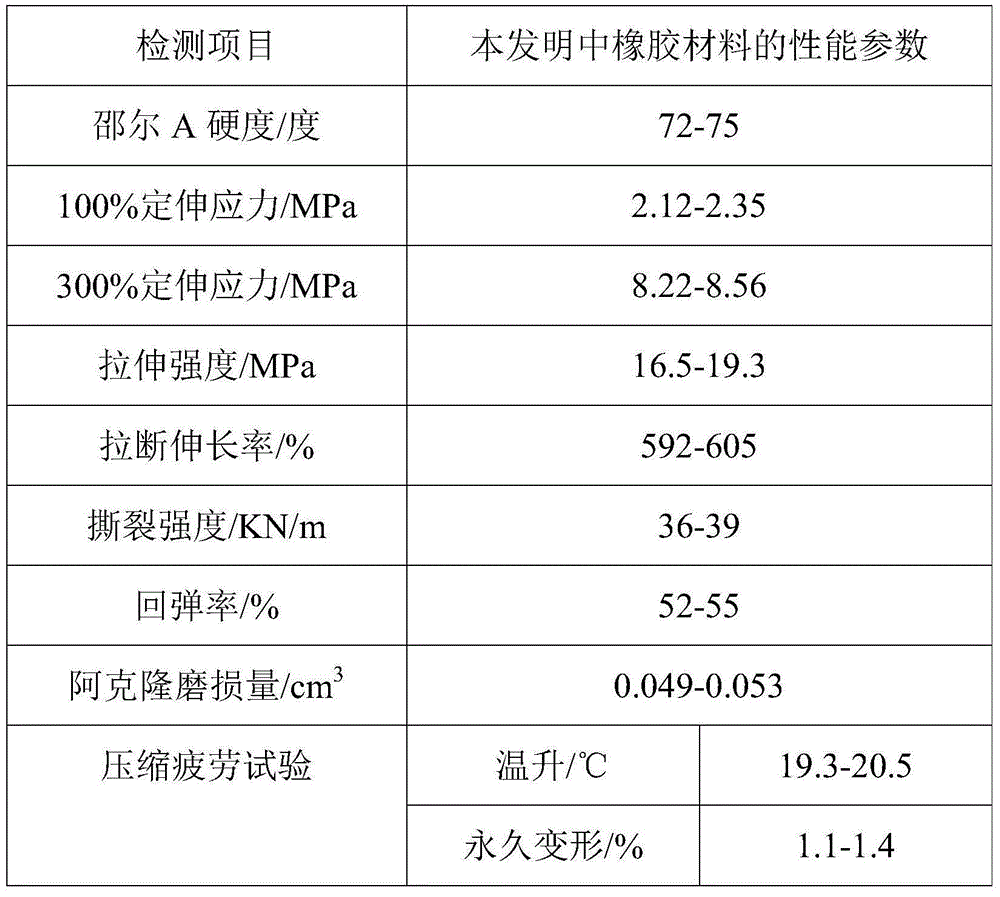

Examples

Embodiment 1

[0018] The special high wear-resistant rubber material for tire tread of the present invention, its raw material comprises the following components by weight: 30 parts of natural rubber, 15 parts of polybutadiene rubber, 15 parts of modified kaolin, stearic acid modified superfine 10 parts of cerium oxide, 3 parts of nano-calcium carbonate, 15 parts of nano-titanium dioxide, 1 part of zinc oxide, 5 parts of stearic acid, 1 part of sulfur, 2 parts of 2-(4-morpholinodithio)benzothiazole, organic 2 parts of silicon-acrylate rubber particles, 5 parts of methyl methacrylate-butadiene-styrene copolymer, 0.1 part of lanthanum di-n-octyl dithiocarbamate, 0.8 part of cobalt yttrium glycine dithiocarbamate , 0.1 part of N-cyclohexylthiophthalimide, 0.5 part of accelerator M, 0.1 part of accelerator CZ, 1 part of antioxidant MB, 0.5 part of lanthanum stearate, 0.1 part of calcium stearate, 3.5 parts of trioctyl trimellitate, 0.3 parts of dimethyl 4-nitrophthalate.

Embodiment 2

[0020] The special high wear-resistant rubber material for tire tread of the present invention, its raw material comprises the following components by weight: 50 parts of natural rubber, 10 parts of polybutadiene rubber, 25 parts of modified kaolin, stearic acid modified superfine 2 parts of cerium oxide, 12 parts of nano-calcium carbonate, 5 parts of nano-titanium dioxide, 5 parts of zinc oxide, 2 parts of stearic acid, 3 parts of sulfur, 0.5 parts of 2-(4-morpholinodithio)benzothiazole, organic 5 parts of silicon-acrylate rubber particles, 1 part of methyl methacrylate-butadiene-styrene copolymer, 0.5 parts of lanthanum di-n-octyl dithiocarbamate, 0.2 parts of cobalt yttrium glycine dithiocarbamate , 0.5 part of N-cyclohexylthiophthalimide, 0.1 part of accelerator M, 0.6 part of accelerator CZ, 0.2 part of antioxidant MB, 1 part of lanthanum stearate, 0.5 part of calcium stearate 1 part, 1 part of trioctyl trimellitate, 0.1 part of dimethyl 4-nitrophthalate;

[0021] Wherei...

Embodiment 3

[0023] The special high wear-resistant rubber material for tire tread of the present invention, its raw material comprises the following components by weight: 42 parts of natural rubber, 13.5 parts of polybutadiene rubber, 20 parts of modified kaolin, stearic acid modified superfine 8 parts of cerium oxide, 7 parts of nano-calcium carbonate, 10 parts of nano-titanium dioxide, 2.3 parts of zinc oxide, 4.1 parts of stearic acid, 1.6 parts of sulfur, 1.8 parts of 2-(4-morpholinodithio)benzothiazole, organic 3.3 parts of silicon-acrylate rubber particles, 3.5 parts of methyl methacrylate-butadiene-styrene copolymer, 0.26 parts of lanthanum di-n-octyl dithiocarbamate, 0.58 parts of cobalt yttrium glycine dithiocarbamate , 0.22 parts of N-cyclohexylthiophthalimide, 0.4 parts of accelerator M, 0.2 parts of accelerator CZ, 0.7 parts of antioxidant MB, 0.7 parts of lanthanum stearate, 0.23 parts of calcium stearate 2.3 parts, 2.3 parts of trioctyl trimellitate, 0.22 parts of dimethyl 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com