Composition and preparation method for preparing wear-resistant waterproof high-elasticity foaming materials

A foaming material and high-elasticity technology, which is applied in the field of rubber-plastic blending foaming manufacturing, can solve the problems of performance degradation such as rebound, compression resistance, material density reduction, unreasonable formula, etc. High crack strength and texture enhancement effect

Inactive Publication Date: 2019-09-20

东莞华工佛塑新材料有限公司

View PDF13 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Due to their special purpose properties and consumer experience needs, shoe soles and cushion products generally have high hardness and high density in order to meet the rebound requirements. At the same time, due to the single material used in the formula and the irrationality of the formula, The weather resistance is relatively poor, the deformation after compression is high, the product is easy to deform, and the wear resistance is poor

To reduce the density of the material, if the existing formula is used, the corresponding performance such as rebound and compression resistance will also decrease significantly.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

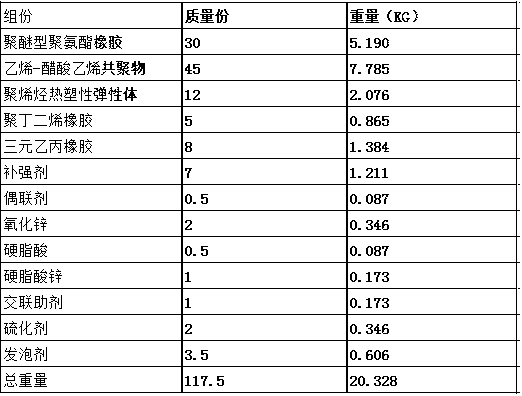

Embodiment 1

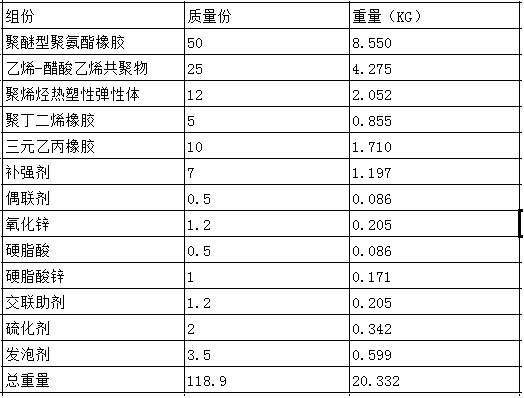

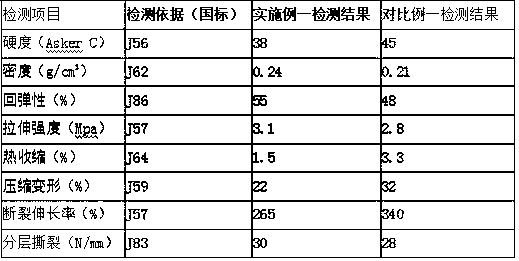

[0039] Compared with Example 1 of the present invention, Comparative Example 1 was produced. In Comparative Example 1, polyethylene-vinyl acetate copolymer TAISOX®7350M was used to replace the polyether polyurethane rubber in the formula of Example 1, and the remaining components remained unchanged.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a composition and a preparation method for high-elasticity wear-resistant foaming materials, wherein the composition comprises, by mass, 20-65 parts of a polyether type polyurethane rubber, 20-65 parts of an ethylene-vinyl acetate copolymer, 7-18 parts of a polyolefin thermoplastic elastomer, 3-8 parts of a polybutadiene rubber, 5-15 parts of ethylene propylene diene monomer, 5-10 parts of a reinforcing agent, 0.3-1 part of a coupling agent, 1.0-2.0 parts of zinc oxide, 0.5-1.0 part of stearic acid, 0.8-1.5 parts of zinc stearate, 0.5-1.5 parts of a cross-linking aid, 1.0-2.5 parts of a vulcanizing agent, and 1.5-3.5 parts of a foaming agent. The preparation method mainly comprises: two mixing, granulation, and foaming. According to the present invention, by adopting the technical scheme, the obtained foaming material product has advantages of small density, softness, wear resistance, excellent anti-cussion performance, good elasticity, compression resistance, small compression deformation and folding deformation resistance.

Description

technical field [0001] The invention relates to the field of rubber-plastic blending and foaming manufacturing, in particular to a composition for preparing highly elastic and wear-resistant foaming materials and a preparation method thereof. Background technique [0002] Due to their special purpose properties and consumer experience needs, shoe soles and cushion products generally have high hardness and high density in order to meet the rebound requirements. At the same time, due to the single material used in the formula and the irrationality of the formula, The weather resistance is relatively poor, the deformation after compression is high, the product is easy to deform, and the wear resistance is poor. To reduce the density of the material, if the existing formula is used, the corresponding performance such as rebound and compression resistance will also decrease significantly. In order to solve the current problems, it is necessary to develop a highly elastic and wea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L75/08C08L23/08C08L23/16C08L9/00C08L23/02C08K13/02C08K3/22C08K5/09C08K5/098C08J9/10C08J9/32

CPCC08J9/0023C08J9/0061C08J9/0066C08J9/0095C08J9/103C08J9/32C08J2203/04C08J2203/22C08J2375/08C08J2409/00C08J2423/02C08J2423/08C08J2423/16

Inventor 邹明清禤文权黎艳飞

Owner 东莞华工佛塑新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com