Belt steel wire cord adhesive gum

A technology of steel cord and adhesive glue, which is applied in the field of rubber tire manufacturing, can solve the problems of increased rubber cost, poor dispersion of silica, and high Mooney viscosity of the mixed rubber, so as to reduce the number of mixing stages and reduce the Effect of Hysteresis Loss and Mooney Viscosity Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

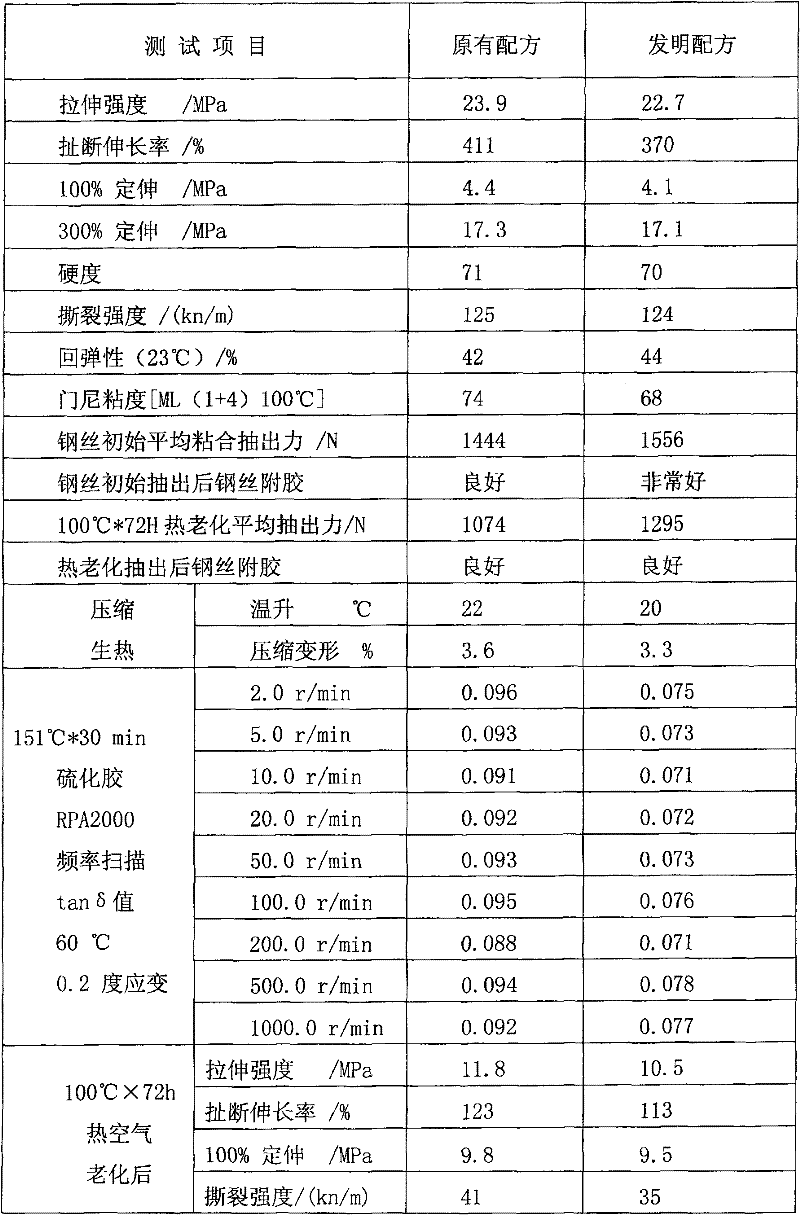

[0022] Embodiment 1 provides a kind of adhesive glue for steel cord of belt layer, its component formula is by the ratio of mass parts:

[0023] 100 parts of natural rubber, 43 parts of carbon black, 15 parts of white carbon black, 8 parts of zinc oxide,

[0024] 1.2 parts of cobalt decanoate, 2.5 parts of anti-aging agent, 1.5 parts of resorcinol,

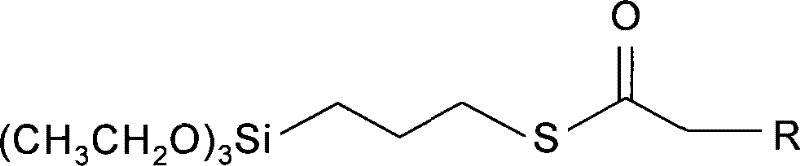

[0025] 5 parts of insoluble sulfur, 5 parts of adhesion promoter, 1.2 parts of sulfenamide accelerator, and 1.5 parts of 3-octanoylthio-1-propyltriethoxysilane newly added in the component formula.

[0026] The added 3-octanoylthio-1-propyl triethoxysilane is used as a coupling agent, which will not be as represented by tetrasulfide silane coupling agents such as SI69 and SI75 used in the prior art, and the increased risk of compound scorch from disulfide silane coupling agents.

[0027] 3-octanoylthio-1-propyltriethoxysilane is used as a coupling agent, its sulfur content is low, and the stability of the generated sulfur-carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com