All-steel radial truck tire tread formula rubber compound, and preparation method and tire thereof

A radial tire and tread technology, applied in the field of all-steel truck radial tire tread compound and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

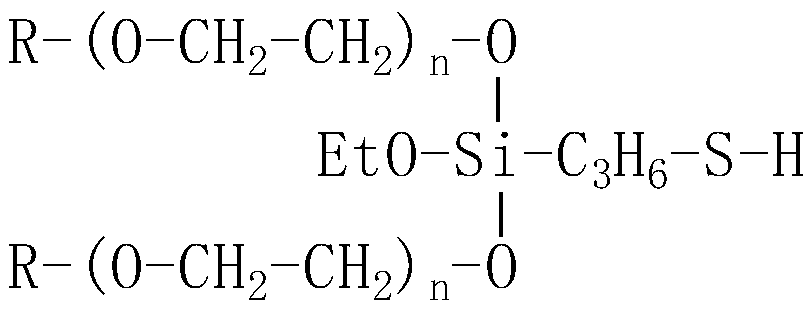

Method used

Image

Examples

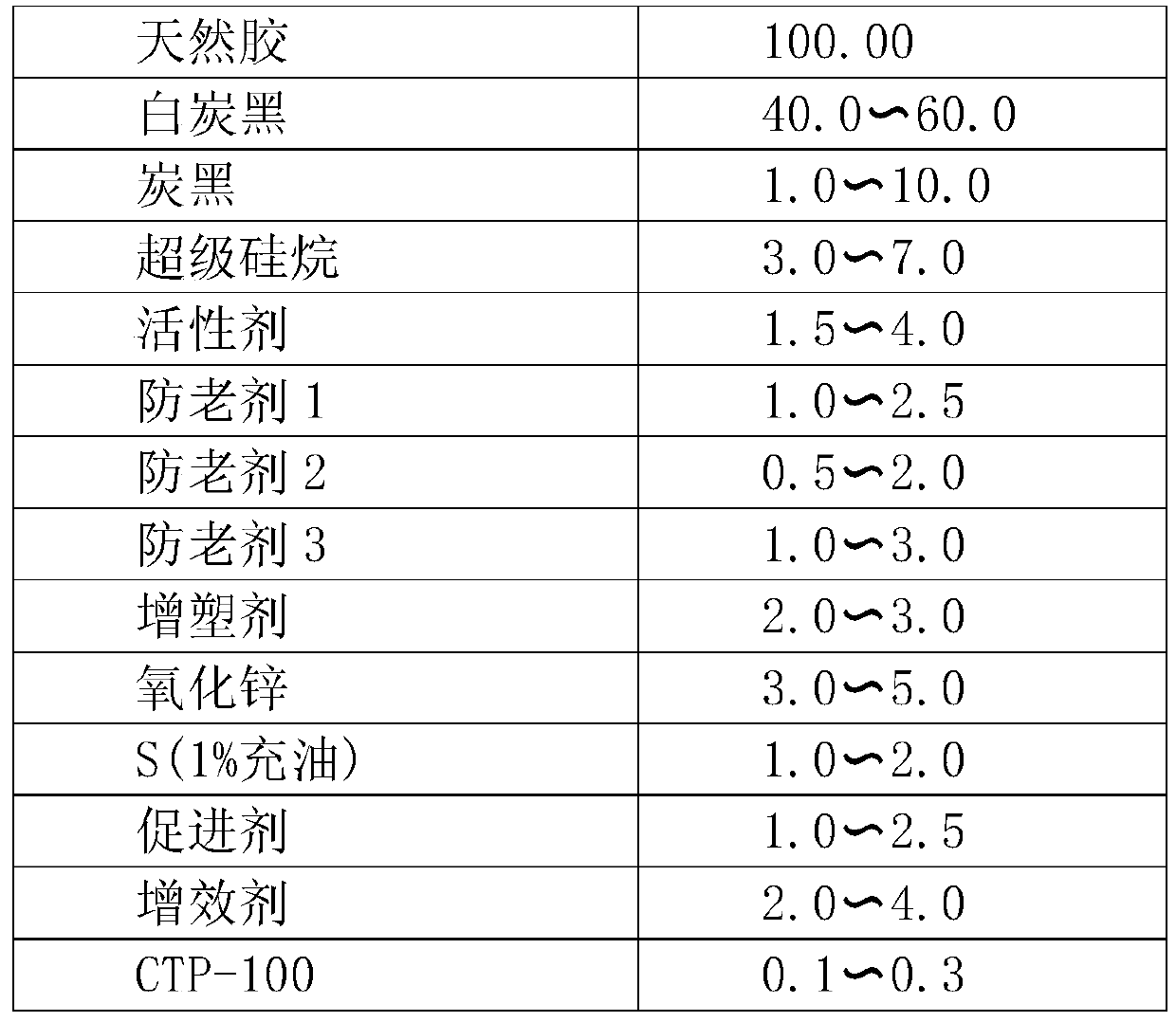

Embodiment 1

[0035]

[0036] In this embodiment, the denominator batching and final batching process of the sizing material preparation method:

[0037] Master refining process:

[0038] 1) Add smoked sheet RSS3# plasticizing rubber, highly dispersed white carbon black, super silane coupling agent, and other masterbatch powders except zinc oxide, press the top bolt to keep

[0039] 2) Raise the top bolt to add carbon black, press the top bolt to raise the temperature of the rubber to 90-120°C;

[0040] 3) Raise the top bolt and add zinc oxide;

[0041] 4) Press the top bolt to heat up the rubber material to

[0042] 5) Press the top bolt to make the rubber Constant temperature mixing Degumming;

[0043] 6) the sizing material is discharged to the lower auxiliary machine mill for pounding glue, and the second mill is cut off for three times, and the second mill is automatically stirred for 1.5 minutes, and the third mill is delivered to go out;

[0044] Final refining process: ...

Embodiment 2

[0048]

[0049] In the present embodiment, the denominator mixing and final mixing process of the compound preparation method are the same as in Example 1

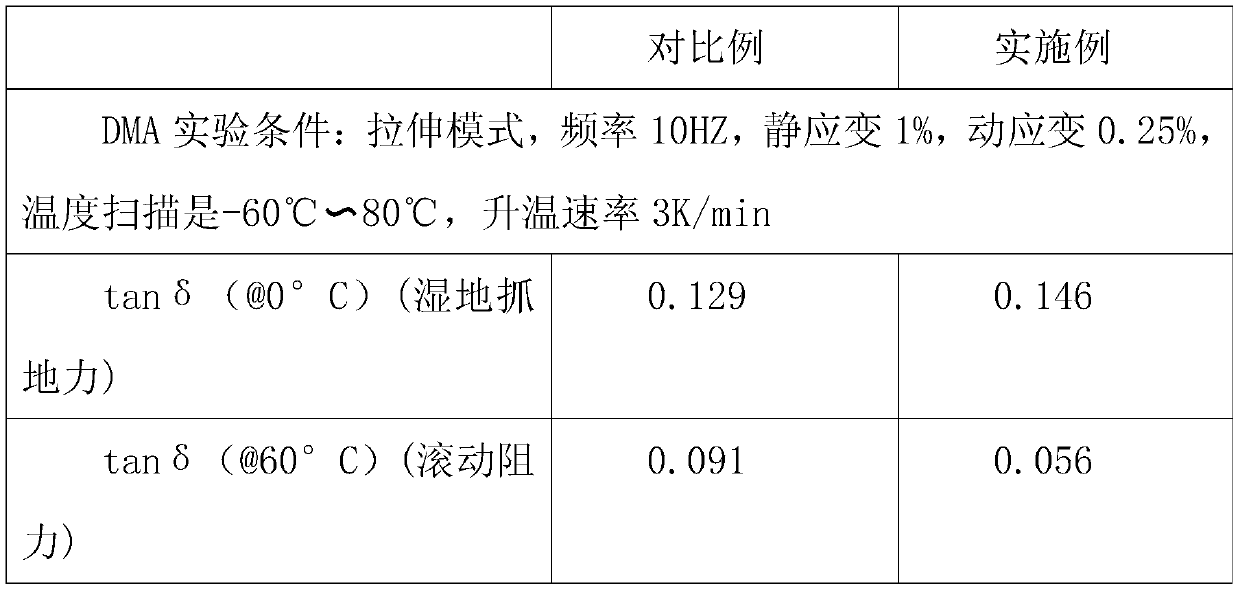

[0050] The low-rolling resistance all-steel radial truck tire tread compound performance test made with the formula of this embodiment

[0051]

[0052] The test data is as follows:

[0053] Embodiment and comparative example tire machine tool and actual vehicle test parameters (tire specification 12R22.518 (L)-288)

[0054]

[0055] The rubber compound formulated in this example has good processing performance in the production process, high processing safety, stable geometric dimensions of the extruded semi-finished product, no return phenomenon, and fully meets the conditions for batch industrial production. The 12R22.5LM288 tire produced using the rubber compound of this example has passed the American SmartWay rolling resistance certification. The tire has excellent fuel consumption and handling performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com