Rubber composition for side rubber and pneumatic radial tire for heavy load using the same

A technology of rubber composition and sidewall rubber, which is applied to the sidewall of the tire, special tires, tire parts, etc., can solve the problems of increased rubber shrinkage, unstable properties, and deterioration of the wear resistance of the sidewall rubber. To achieve the effect of reducing rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

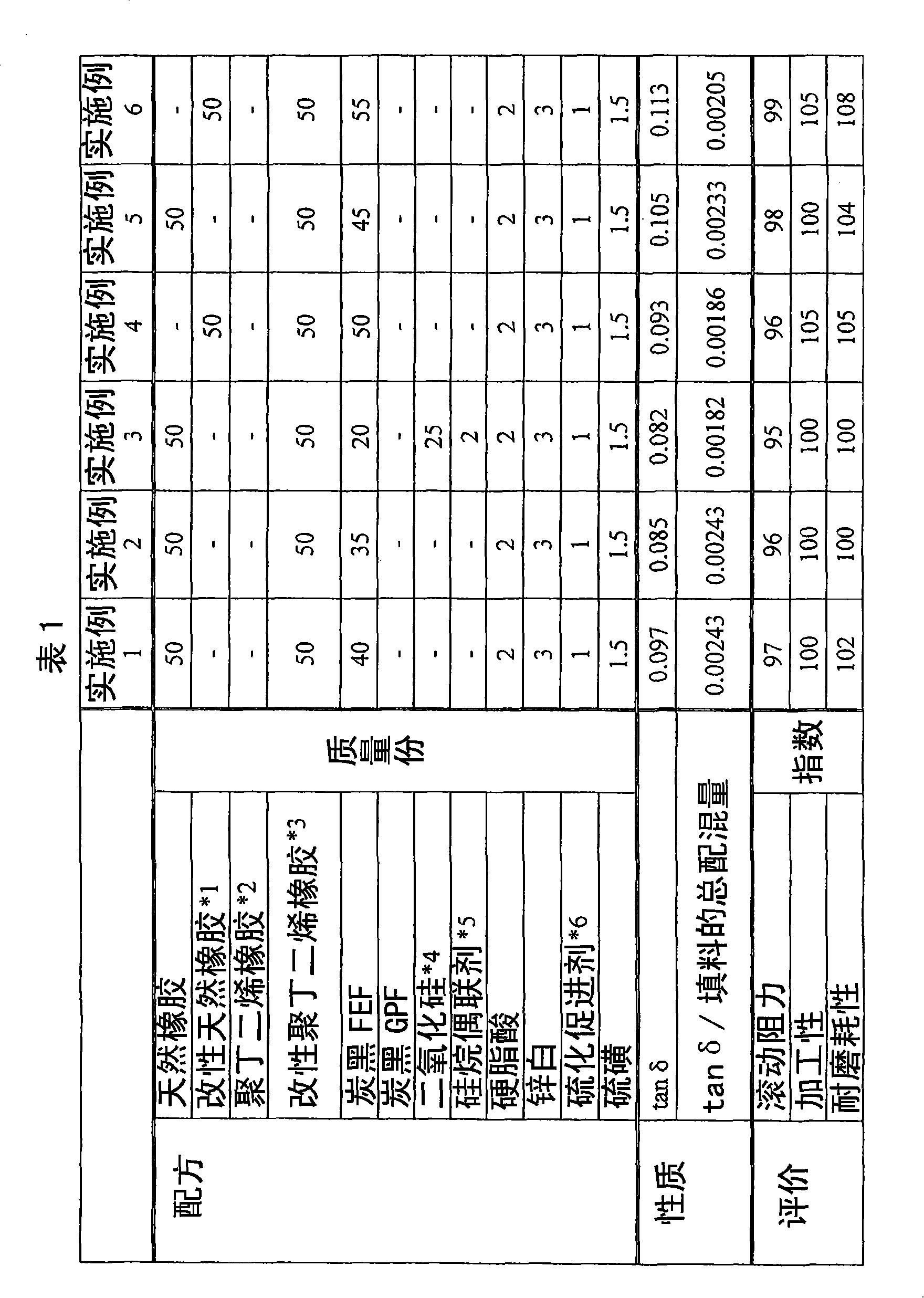

[0017] The present invention will be described in detail below. The rubber composition for a sidewall rubber according to the present invention includes 35 to 55 parts by mass of a filler containing at least carbon black having a grade of not lower than FEF, based on 100 parts by mass of at least one of natural rubber and synthetic polyisoprene rubber. A rubber component composed of one and the other synthetic diene-based rubber, wherein the amount of carbon black compounded with a grade not lower than FEF is 15 to 55 parts by mass, the total compounding of tan δ at 25°C and filler The amount satisfies the relationship of the above formula (I).

[0018] To improve the durability and processability of the sidewall rubber, it is generally effective to increase the total amount of fillers such as carbon black, silica, and the like. On the other hand, in order to reduce the rolling resistance, it is effective to reduce the hysteresis loss (tan δ) of the side rubber. Based on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com