Medical device

A technology for medical use and equipment, applied in biochemical equipment and methods, medical science, pharmaceutical formulations, etc., can solve the problems of increased non-specific adsorption, poor detection accuracy, and dissolution of solidified layer components, so as to achieve the reduction of dissolved substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0186] Examples are shown below to describe the present invention in detail. However, the present invention is not limited by the following description. Unless otherwise stated, "%" means "mass %". Examples 1-6 and Examples 13-14 are examples, and Examples 7-12 are comparative examples.

[0187] (Synthesis and preparation of compound (X))

[0188]

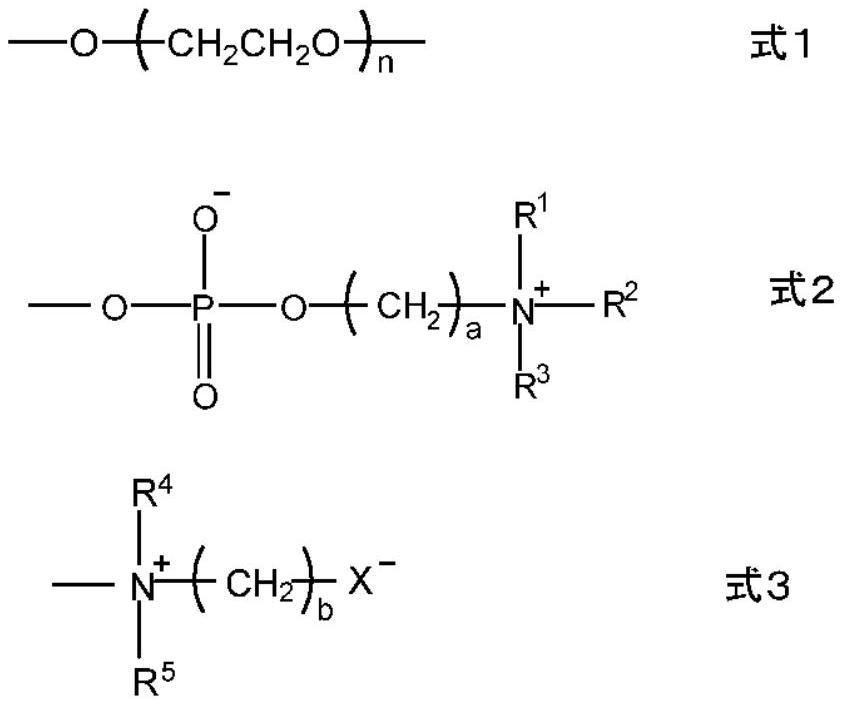

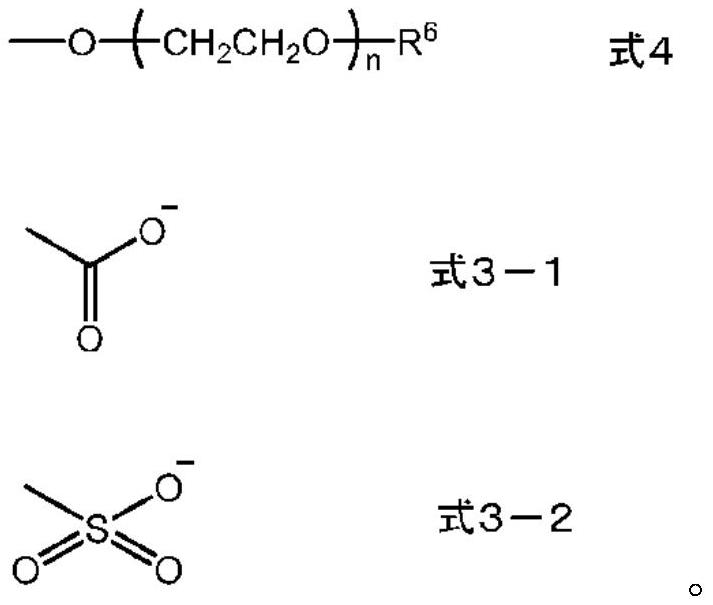

[0189] Compounds belonging to compound (X1) and compounds having no bioaffinity group used in Comparative Examples were synthesized or prepared as follows.

[0190] Compound (X11-1); as the compound (X11-1) of the structure shown below, that is, 2-[methoxy(polyoxyethylene) 9-12 Propyl]trimethoxysilane was prepared as a commercial item SIM6492.72 (trade name, manufactured by Gelest Corporation). Compound (X11-1) is that the terminal hydrogen atom of compound (X11) is replaced by a methyl group, n1 is 9-12, Q 1 for-C 3 h 6 -, t is 3, R 8 For methyl compounds.

[0191]

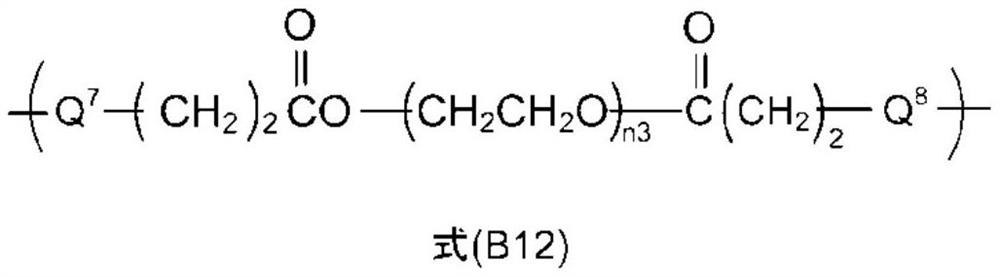

[0192] Compound (X11-2); the compound (X11-2) havi...

manufacture example 1

[0209] Add HEMA 57.0g (438mmol), KBM-503 3.00g (12.1mmol), 1-methoxy-2-propanol 119g, diacetone alcohol 21g, and 2,2'-azo to a 500mL 3-neck flask Dimethyl bis(2-methylpropionate) 600 mg (2.61 mmol). The monomer concentration in the reaction liquid was 30% by mass, and the initiator concentration was 1% by mass. Next, the obtained mixture was stirred at 75° C. under a nitrogen atmosphere for 16 hours, and then left to cool to room temperature to obtain a colorless transparent liquid (a solution containing 30% by mass of the copolymer (X21-1)). The yield was 200 g, and the yield was 100%.

manufacture example 2~4

[0211] In Production Example 1, copolymers (X21-2) and (X21-3) were produced in the same manner except that the monomer composition was changed as shown in Table 2. In addition, homopolymers (M) of monomers having biocompatible groups are produced.

[0212] Mw of the compound (copolymer) obtained in Production Examples 1 to 4, (CH in group 1 (4) 2 CH 2 O), the number of repetitions (n2), the ratio (mass %) of the bioaffinity group (group 1 (4)) in the compound, and the ratio (mass %) of the alkoxysilyl group are shown in Table 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com