Solid-phase substrate as well as preparation method and application thereof

一种基底、基团的技术,应用在固相基底及其制备领域,能够解决影响测序质量、稳定性差、核酸分子分布密度不易控制等问题,达到提高芯片质量、改善性能、改善测序质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

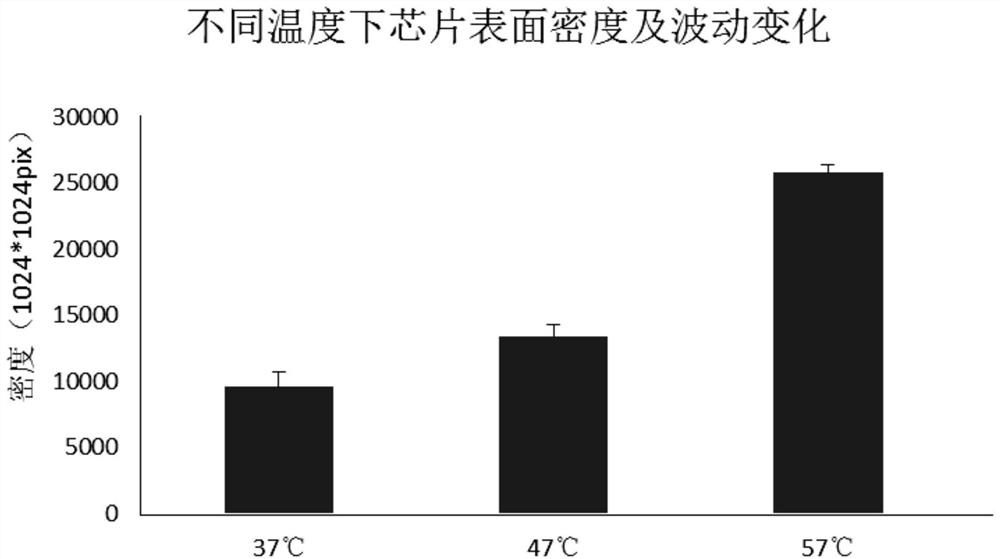

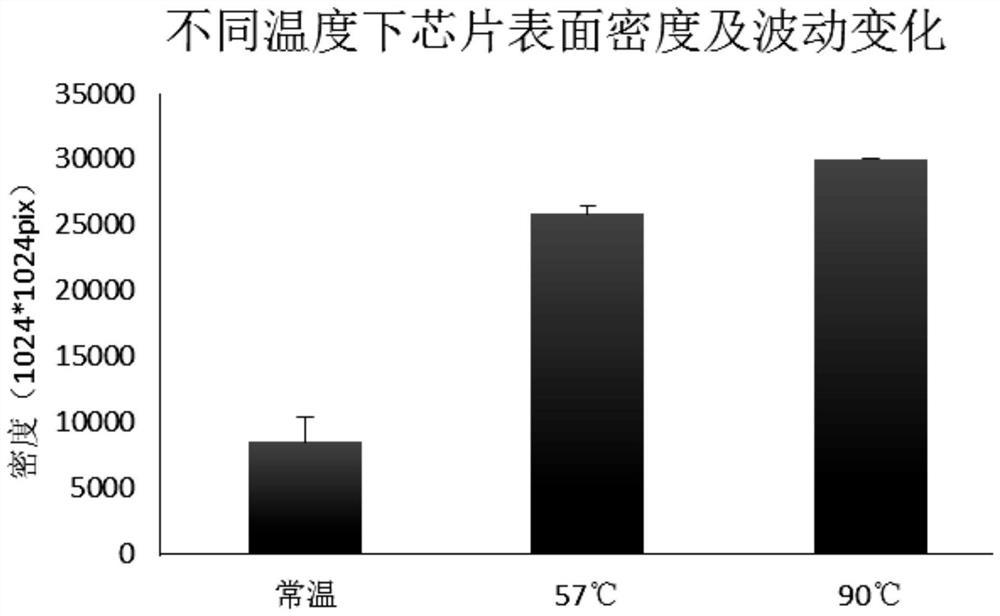

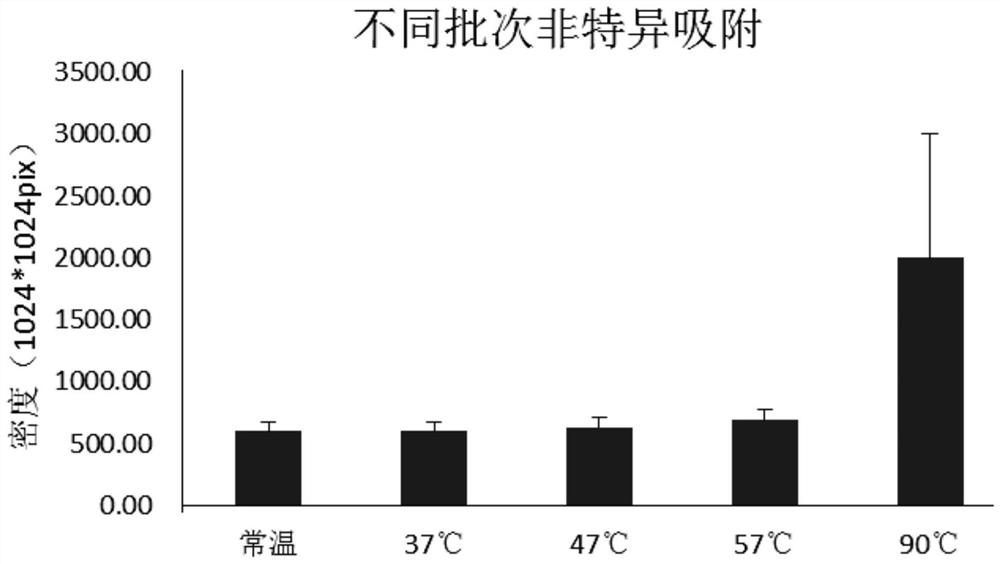

[0089] Example 1 Place at 57°C after silanization

[0090] (1) Cleaning the glass substrate: clean the surface with 5% (mass concentration) hydrochloric acid for 3 hours;

[0091] (2) Activated glass substrate: soaked in piranha solution for 30 minutes, washed with ultrapure water for 5 times, and washed with ethanol once (surface hydroxylation);

[0092] (3) Surface silane derivatization reaction: prepare 2% (mass concentration) GOPTS (3-(2,3-glycidoxy)propyltrimethoxysilane) ethanol solution, react at 37°C for 5 hours, and then purify 5 times Wash with water, 5 times of ethanol, 1 time of acetone, dry with nitrogen, and set aside;

[0093] (4) Low temperature placement treatment: place the prepared chips in a nitrogen drying cabinet, placement conditions: temperature 57°C, relative humidity 55%, placement time 4 days;

[0094] (5) Amino-DNA-CY3 molecule immobilization: prepare 0.25M phosphate buffer containing amino-DNA-CY3 molecules, coat the surface, react at 37°C for 10...

Embodiment 2

[0096] Example 2 Place at 47°C after silanization

[0097] (1) Cleaning the glass substrate: clean the surface with 5% (mass concentration) hydrochloric acid for 3 hours;

[0098] (2) Activated glass substrate: soaked in piranha solution for 30 minutes, washed with ultrapure water for 5 times, and washed with ethanol once;

[0099] (3) Surface silane derivatization reaction: prepare 2% (mass concentration) GOPTS ethanol solution, react at 37° C. for 5 hours, then clean with 5 times of pure water, 5 times of ethanol and 1 time of acetone, dry with nitrogen, and set aside for later use;

[0100] (4) Low temperature placement treatment: place the prepared chips in a nitrogen drying cabinet, placement conditions: temperature 47°C, relative humidity 55%, placement time 4 days;

[0101] (5) Amino-DNA-CY3 molecule immobilization: prepare 0.25M phosphate buffer containing amino-DNA-CY3 molecules, coat the surface, react at 37°C for 10 hours, and then cross-wash with 1XPBS (pH=7.4) an...

Embodiment 3

[0103] Example 3 Place at 37°C after silanization

[0104] (1) Cleaning the glass substrate: clean the surface with 5% (mass concentration) hydrochloric acid for 3 hours;

[0105] (2) Activated glass substrate: soaked in piranha solution for 30 minutes, washed with ultrapure water for 5 times, and washed with ethanol once;

[0106] (3) Surface silane derivatization reaction: prepare 2% (mass concentration) GOPTS ethanol solution, react at 37° C. for 5 hours, then clean with 5 times of pure water, 5 times of ethanol and 1 time of acetone, dry with nitrogen, and set aside for later use;

[0107] (4) Low temperature placement treatment: place the prepared chips in a nitrogen drying cabinet, placing conditions: temperature 37°C, relative humidity 55%, placement time 4 days;

[0108] (5) Amino-DNA-CY3 molecule immobilization: prepare 0.25M phosphate buffer containing amino-DNA-CY3 molecules, coat the surface, react at 37°C for 10 hours, and then cross-wash with 1XPBS (pH=7.4) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com