Solid phase substrates, their processing methods and uses

A substrate and relative humidity technology, applied in the field of nucleic acid chips, can solve the problems of instability and difficult to control the stability of the distribution density of nucleic acid molecules, and achieve the effects of reducing non-specific adsorption, improving sequencing quality, and improving interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

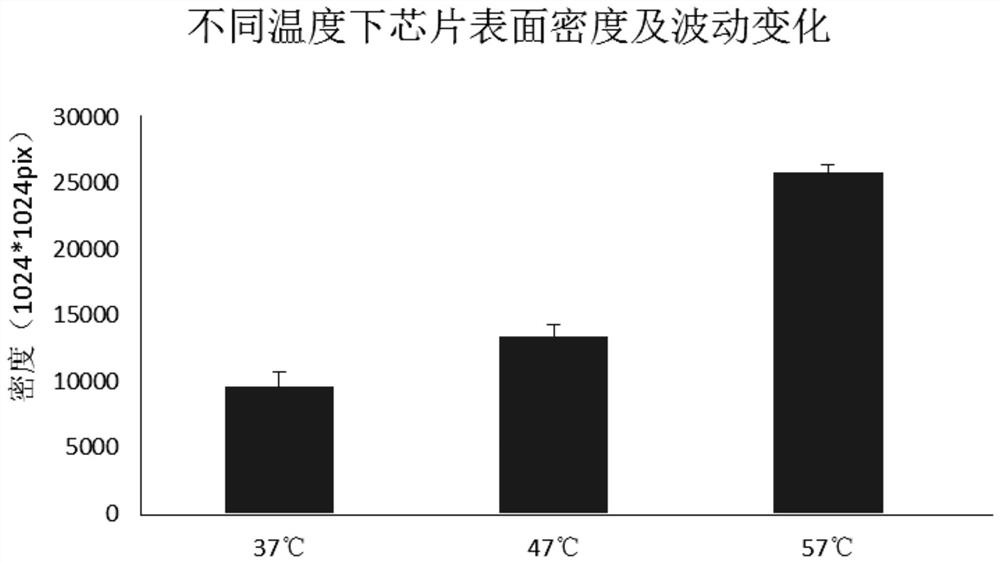

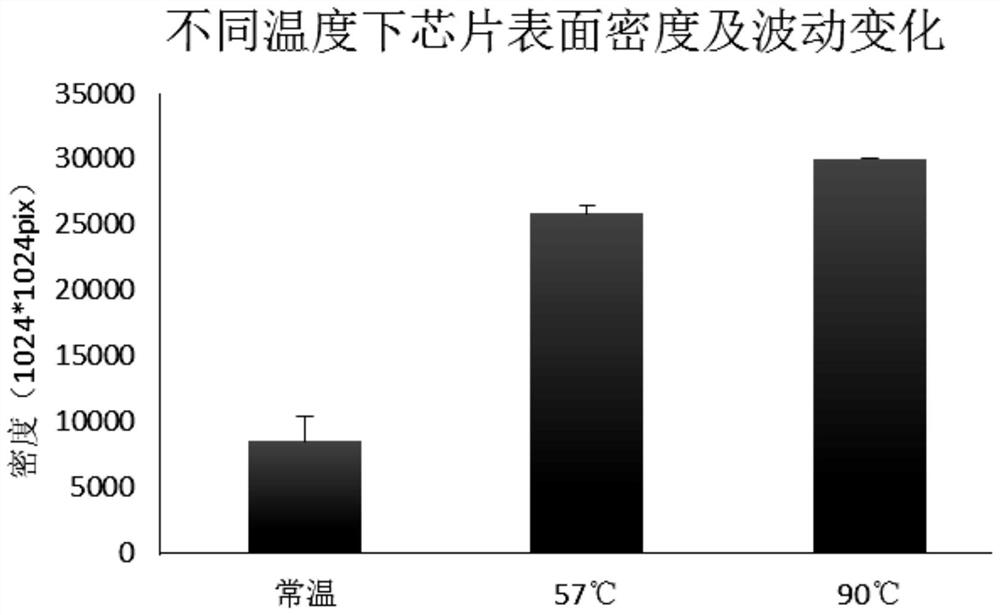

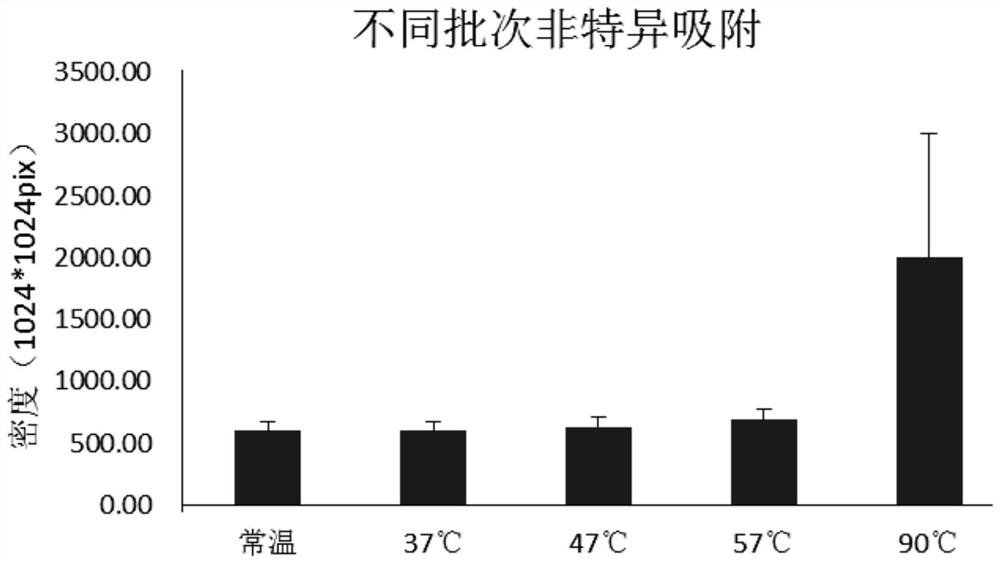

[0089] Placed at 57°C after silanization in Example 1

[0090] (1) cleaning the glass substrate: cleaning the surface with 5% (mass concentration) hydrochloric acid for 3 hours;

[0091] (2) Activated glass substrate: soak in piranha solution (piranha solution) for 30 minutes, wash 5 times with ultrapure water, and wash 1 time with ethanol (surface hydroxylation);

[0092] (3) Surface silane derivatization reaction: Prepare 2% (mass concentration) GOPTS (3-(2,3-glycidyloxy)propyltrimethoxysilane) ethanol solution, react at 37°C for 5 hours, and then purify Wash with water, 5 times of ethanol, 1 time of acetone, blow dry with nitrogen, and set aside;

[0093] (4) Low-temperature placement treatment: place the prepared chip in a nitrogen drying cabinet, placement conditions: temperature 57°C, relative humidity 55%, placement time 4 days;

[0094] (5) Immobilization of amino-DNA-CY3 molecules: Prepare 0.25M phosphate buffer solution containing amino-DNA-CY3 molecules, spread on t...

Embodiment 2

[0096] Placed at 47°C after silanization in Example 2

[0097] (1) cleaning the glass substrate: cleaning the surface with 5% (mass concentration) hydrochloric acid for 3 hours;

[0098] (2) Activated glass substrate: soak in piranha solution for 30 minutes, wash with ultrapure water for 5 times, and wash with ethanol once;

[0099] (3) Surface silane derivatization reaction: prepare 2% (mass concentration) GOPTS ethanol solution, react at 37°C for 5 hours, then wash with pure water 5 times, ethanol 5 times, and acetone once, blow dry with nitrogen, and set aside;

[0100] (4) Low-temperature placement treatment: place the prepared chip in a nitrogen drying cabinet, placement conditions: temperature 47°C, relative humidity 55%, placement time 4 days;

[0101] (5) Immobilization of amino-DNA-CY3 molecules: Prepare 0.25M phosphate buffer solution containing amino-DNA-CY3 molecules, spread on the surface, react at 37°C for 10 hours, and then cross-wash with 1XPBS (pH=7.4) and pu...

Embodiment 3

[0103] Example 3 Placed at 37°C after silanization

[0104] (1) cleaning the glass substrate: cleaning the surface with 5% (mass concentration) hydrochloric acid for 3 hours;

[0105] (2) Activated glass substrate: soak in piranha solution for 30 minutes, wash with ultrapure water for 5 times, and wash with ethanol once;

[0106] (3) Surface silane derivatization reaction: prepare 2% (mass concentration) GOPTS ethanol solution, react at 37°C for 5 hours, then wash with pure water 5 times, ethanol 5 times, and acetone once, blow dry with nitrogen, and set aside;

[0107] (4) Low-temperature placement treatment: place the prepared chip in a nitrogen drying cabinet, placement conditions: temperature 37°C, relative humidity 55%, placement time 4 days;

[0108] (5) Immobilization of amino-DNA-CY3 molecules: Prepare 0.25M phosphate buffer solution containing amino-DNA-CY3 molecules, spread on the surface, react at 37°C for 10 hours, and then cross-wash with 1XPBS (pH=7.4) and pure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com