Patents

Literature

30results about How to "Reduce the risk of non-conformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

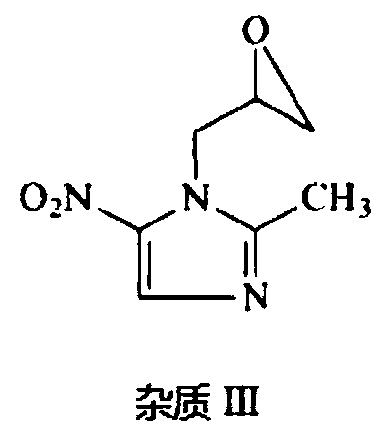

Wear-resistant irradiation cross-linked polyvinyl chloride (PVC) insulating material for automotive original line and preparation method thereof

InactiveCN104262851ASolve the problem that the low temperature cannot passImprove wear resistancePlastic/resin/waxes insulatorsCross-linkElectrical conductor

The invention discloses a wear-resistant irradiation cross-linked polyvinyl chloride (PVC) insulating material for an automotive original line and a preparation method thereof. The wear-resistant irradiation cross-linked polyvinyl chloride insulating material for the automotive original line comprises the following components in part by weight: 40-60 parts of PVC resin powder with a molecular weight of 1300, 25-50 parts of chlorinated polyethylene material, 5-15 parts of a PVC modifier, 5-15 parts of a PVC non-toxic plasticizer and stabilizer, 30-70 parts of trimellitic acid ester 380, 5-10 parts of a calcium / zinc compound stabilizer, 15-50 parts of nano calcium carbonate, 0.2-1.5 parts of an antioxidant, 5-15 parts of a sensitizer, 0.1-0.6 part of an alcohol ester type compound lubricant and 0-1 part of impurities incapable of changing the component property. The wear-resistant irradiation cross-linked polyvinyl chloride (PVC) insulating material and the preparation method thereof have the benefits that the problem that a large square conductor cable cannot pass at a low temperature is solved, the problem that a small square conductor cable cannot pass after being scraped and abraded is also solved, the problem of narrow irradiation dose range during irradiation crosslinking is also solved, and the risk of disqualification after irradiation crosslinking is reduced.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

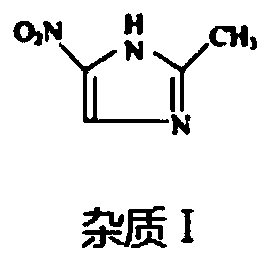

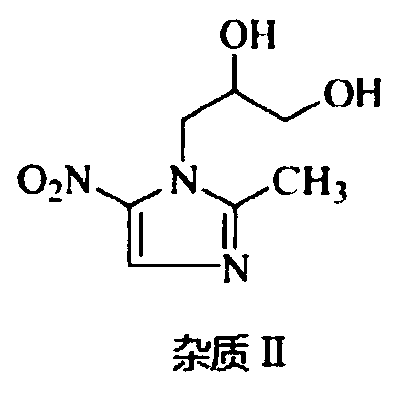

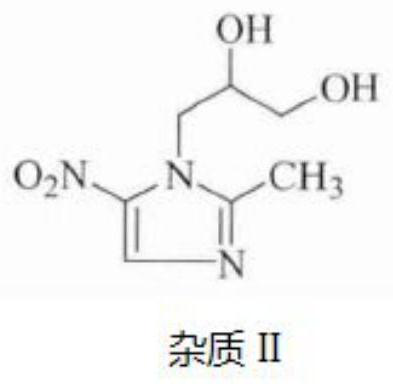

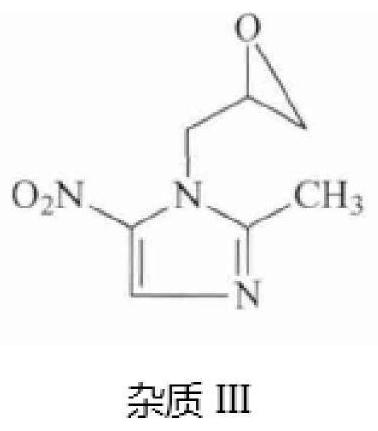

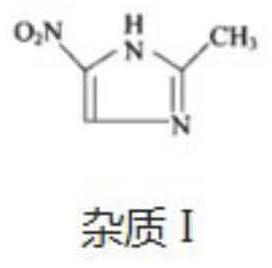

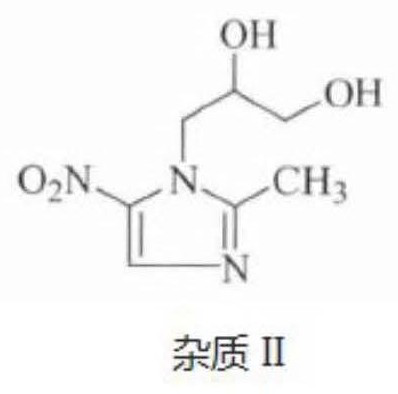

Solvent system capable of effectively dissolving ornidazole or levorotatory ornidazole and injection thereof

ActiveCN110917135AAvoid defectsReduce dosageAntibacterial agentsOrganic active ingredientsIrritationPolythylene glycol

The invention discloses a solvent system capable of effectively dissolving ornidazole or levorotatory ornidazole and an injection thereof, the active component is ornidazole or levorotatory ornidazole, and the solvent system is an organic solvent formed by mixing short-chain polyethylene glycol and ethanol; the short-chain polyethylene glycol is preferably polyethylene glycol 300 or / and polyethylene glycol 400. Wherein the mixed mass fraction ratio of the short-chain polyethylene glycol to the ethanol in the solvent system is (30-100): (0-70). The method has the technical advantages which cannot be achieved by the prior art; the ornidazole injection or levorotatory ornidazole injection has the unique preparation advantages of simpler prescription, safer production, more stable preparation,less solvent amount, lower impurity (particularly genotoxic impurities) content, fewer impurities, low-temperature crystallization difficulty, low phlebitis occurrence rate, no low-pH infusion irritation, no propylene glycol and the like; the clinical medication safety is ensured, and the medication compliance of a patient is better.

Owner:SOUTHWEST UNIVERSITY +1

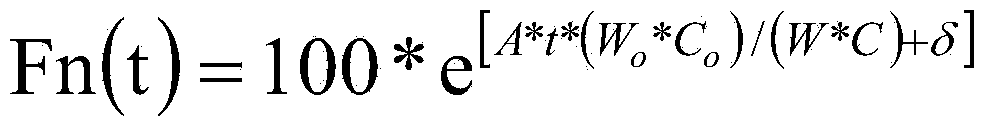

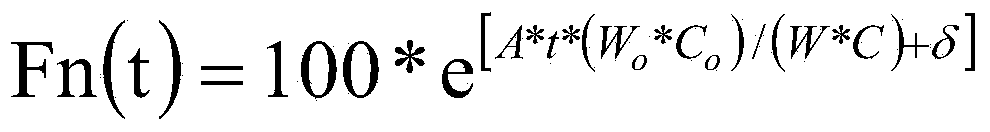

Modeling method of mathematical model used for predicting plastic pipeline aging tendency

InactiveCN104008280ASmall relative errorFor easy referenceSpecial data processing applicationsModel methodMathematical model

The invention relates to the technology of analysis of building plastic pipeline aging performance, and discloses a modeling method of a mathematical model used for predicting a plastic pipeline aging tendency. The tensile strength conservation rate of a plastic pipeline is measured according to the determined temperature impact factor, the place impact factor and the time impact factor, and the index function relation between the tensile strength conservation rate and the temperature impact factor, the place impact factor and the time impact factor can be referred to in the instruction. According to the method, an indoor aging mathematical model formula has a smaller relative error value, the variation tendency of indoor natural aging tensile performance of plastic pipe materials used for buildings can be well fit, and the modeling method provides a good reference basis for predicting the plastic pipeline aging situation.

Owner:ZHEJIANG INST OF QUALITY INSPECTION SCI

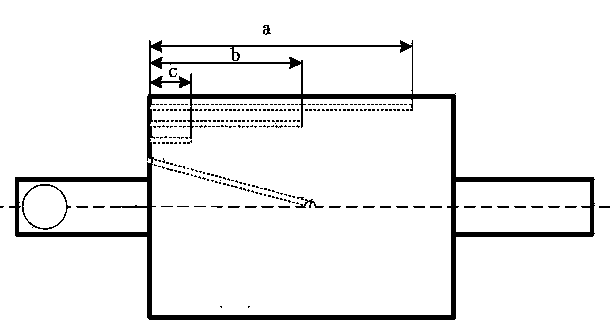

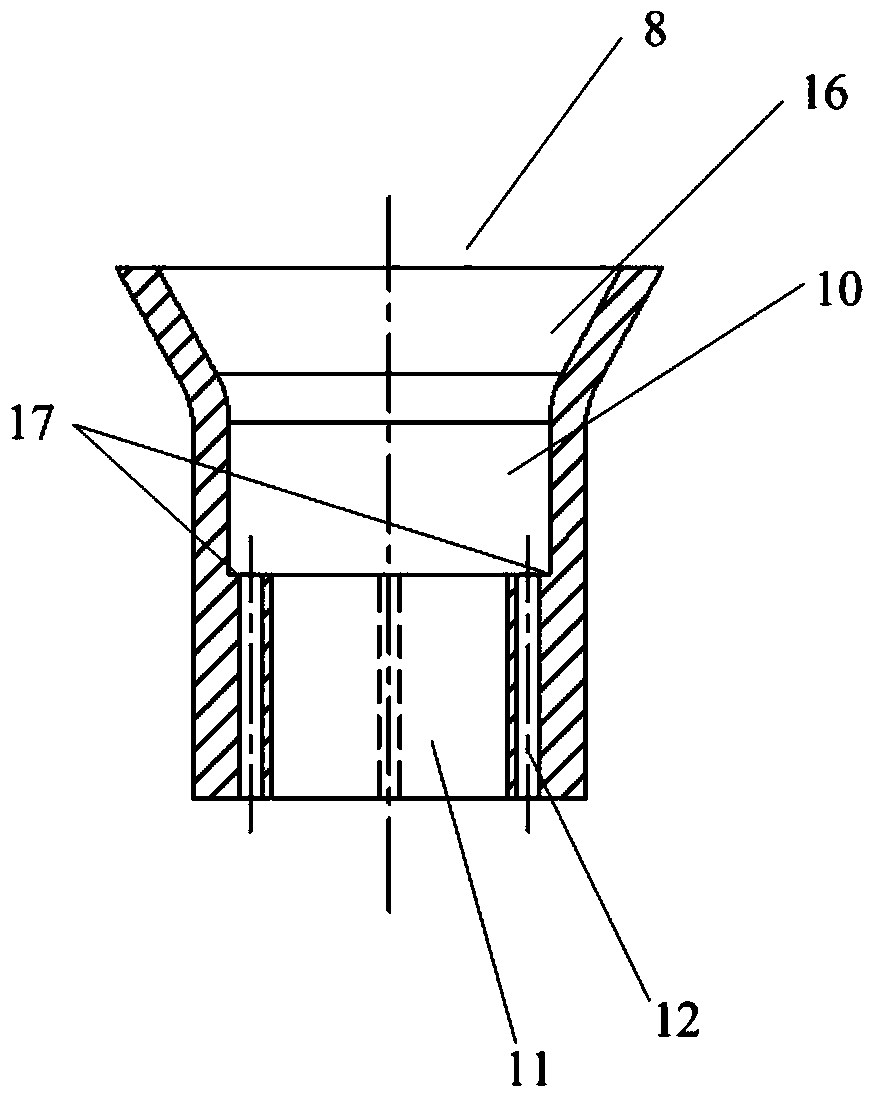

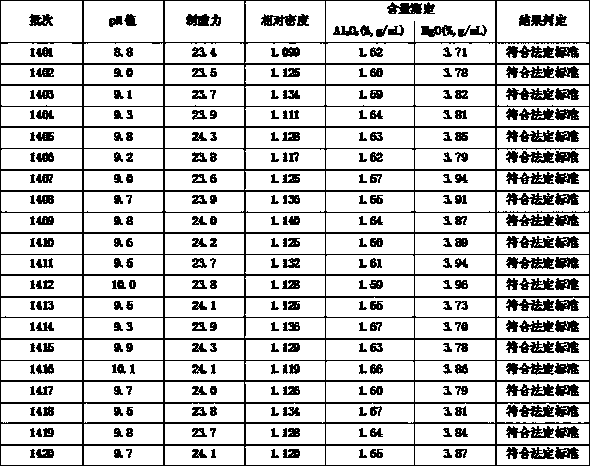

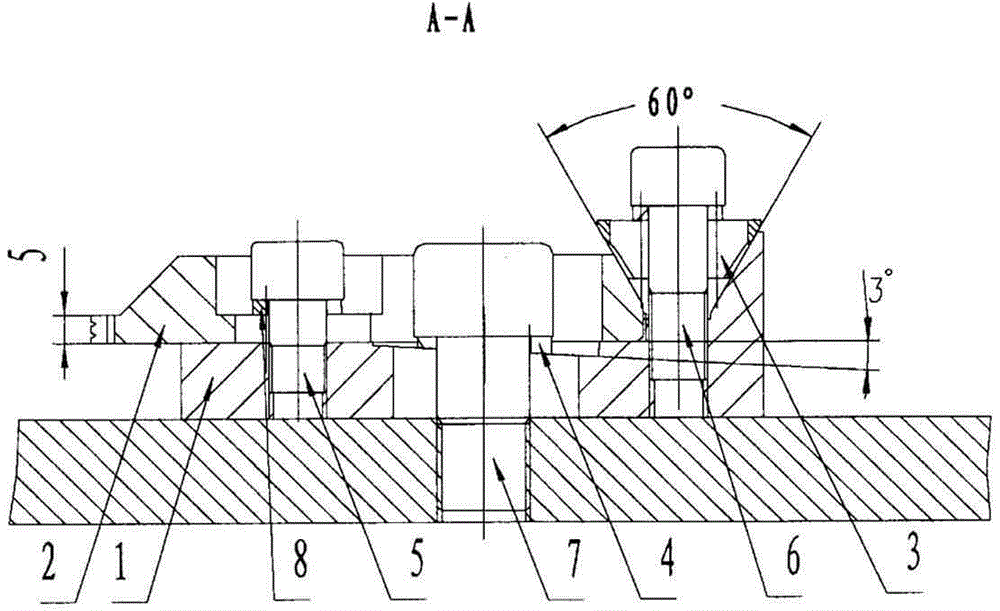

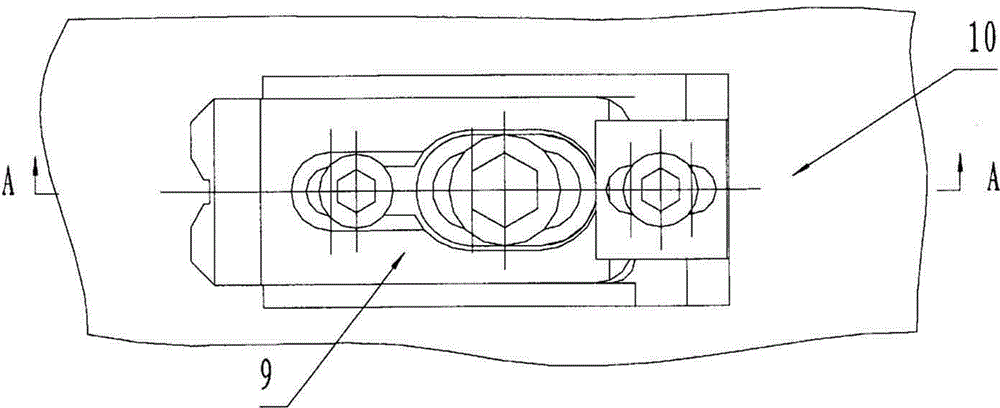

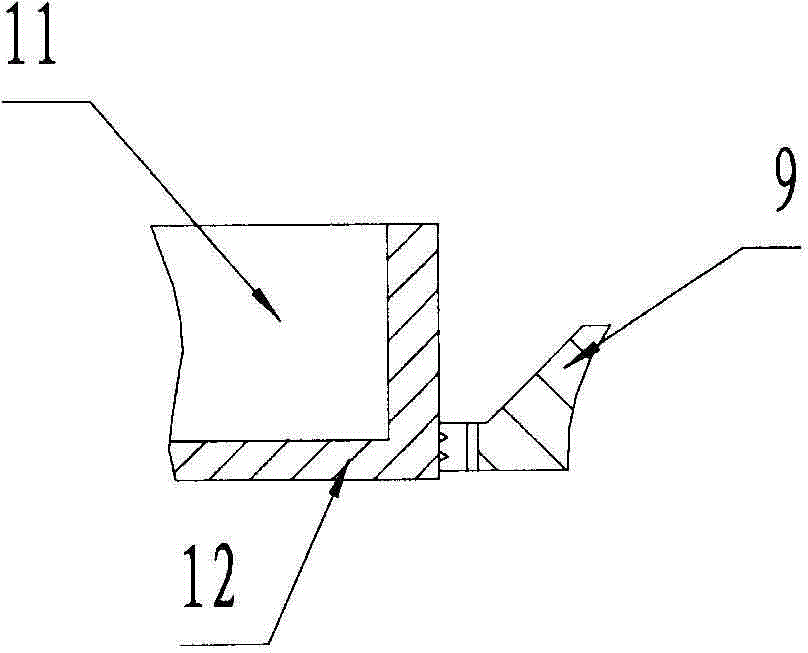

Special machining tool base for special type steel cylinder opening and machining method

PendingCN108747230AImprove stabilityAvoid force imbalanceOther manufacturing equipments/toolsEngineeringSlide plate

The invention discloses a special machining tool base for a special type steel cylinder opening. The special machining tool base comprises a medium sliding plate, a small sliding plate, a square toolrest, a first servo motor and a second servo motor. The square tool rest is in a square shape, and four tool positions are arranged at the four corners. An additional tool base is further arranged onthe medium sliding plate, located at the transverse position of the square tool rest, and provided with one tool position. The four tool positions of the square tool rest sequentially include the first tool position, the second tool position, the fourth tool position and the fifth tool position, and the additional tool base is provided with the third tool position. A turning tool is installed at the first tool position, a turning tool is installed at the second tool position, a drilling tool is installed at the third tool position, a boring tool is installed at the fourth tool position, and aturning tool is installed at the fifth tool position. The tool base is specially used for machining a cylinder opening of a transverse handle type medium-small-volume steel cylinder, one device is provided with the five tools at the same time, and the steel cylinder machining requirement can be met through one-time workpiece clamping. The invention further discloses a method adopting the above special tool base to machine the special type steel cylinder opening.

Owner:SHANDONG CONSTR HIGH PRESSURE CONTAINER

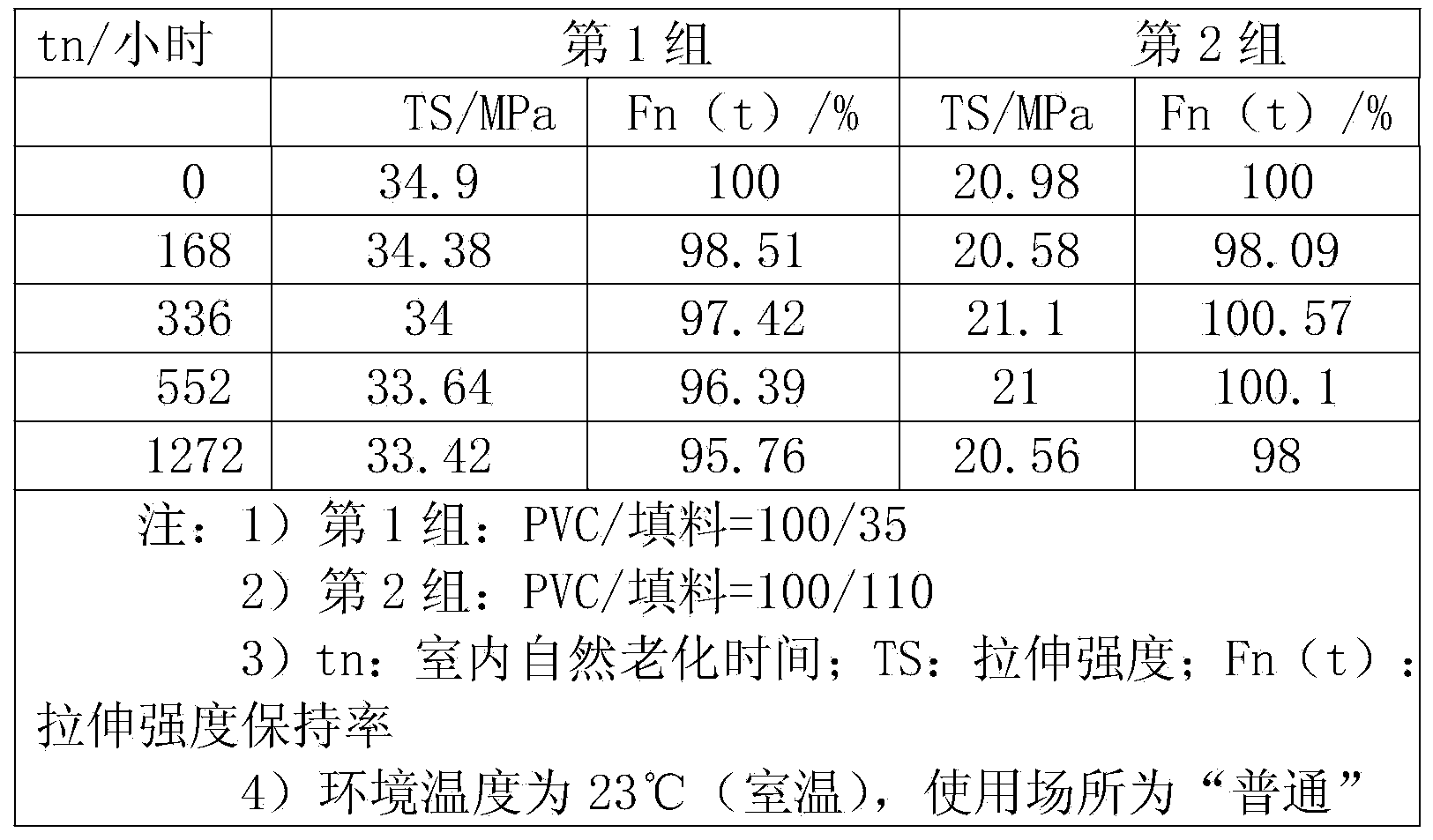

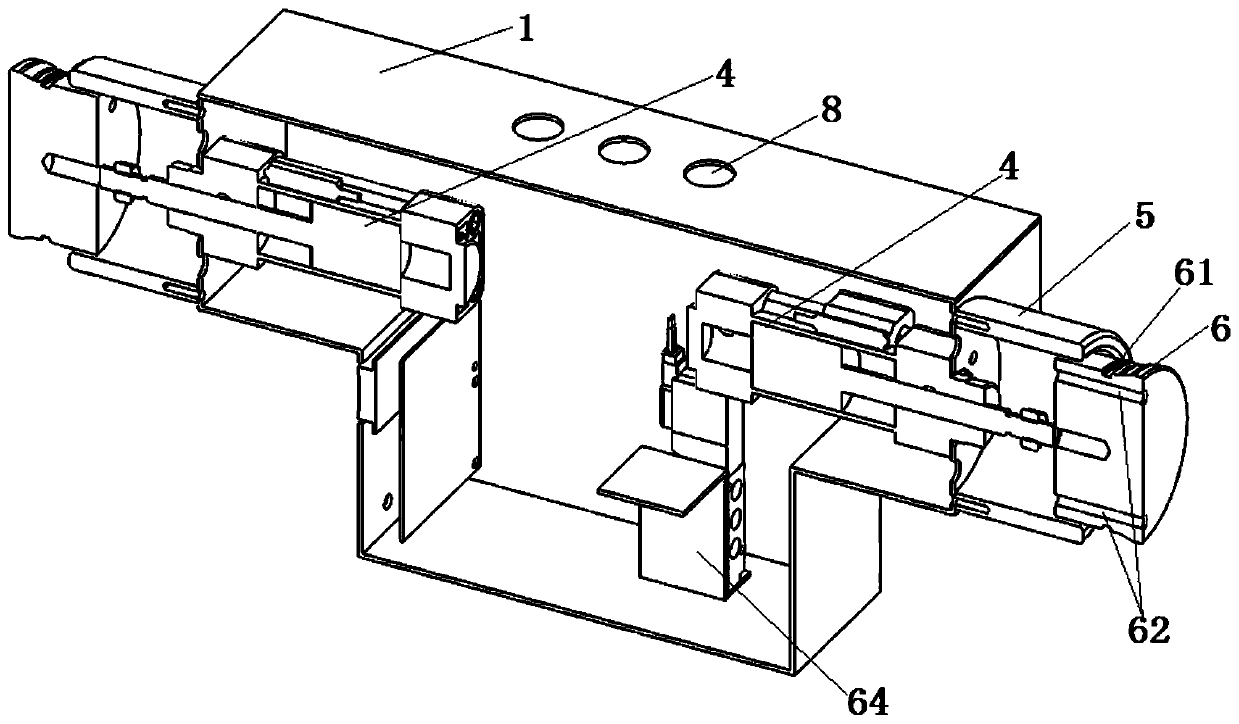

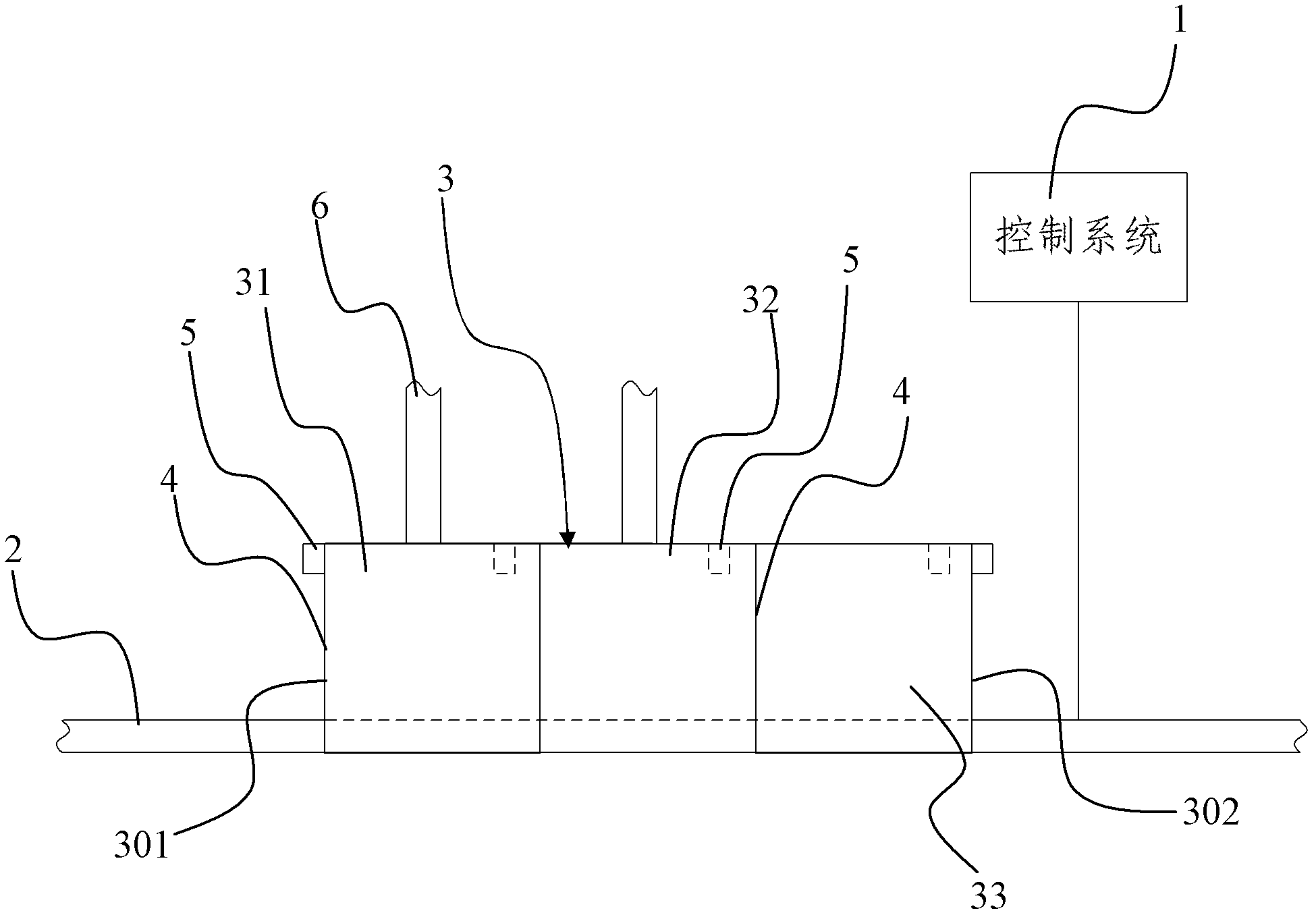

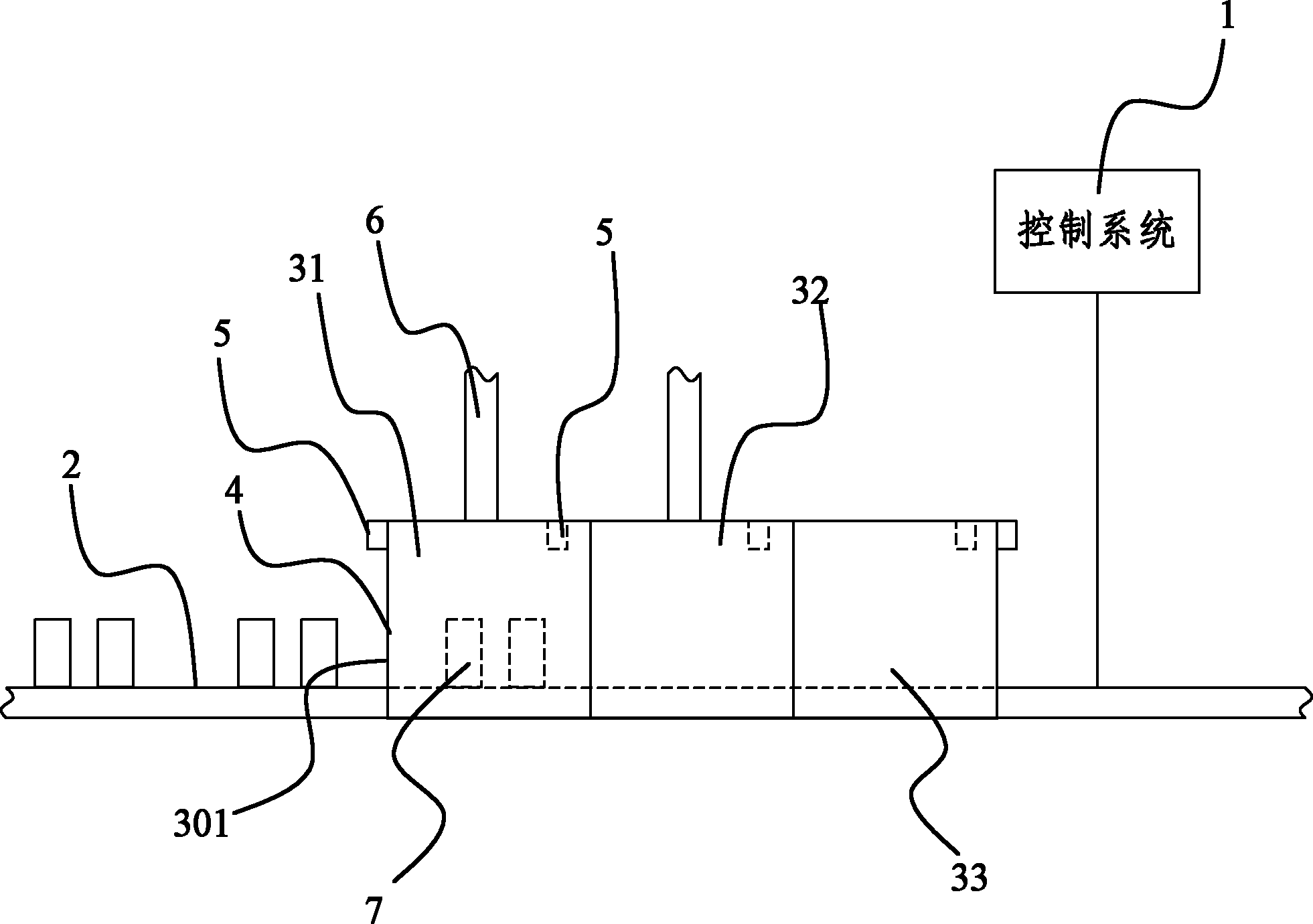

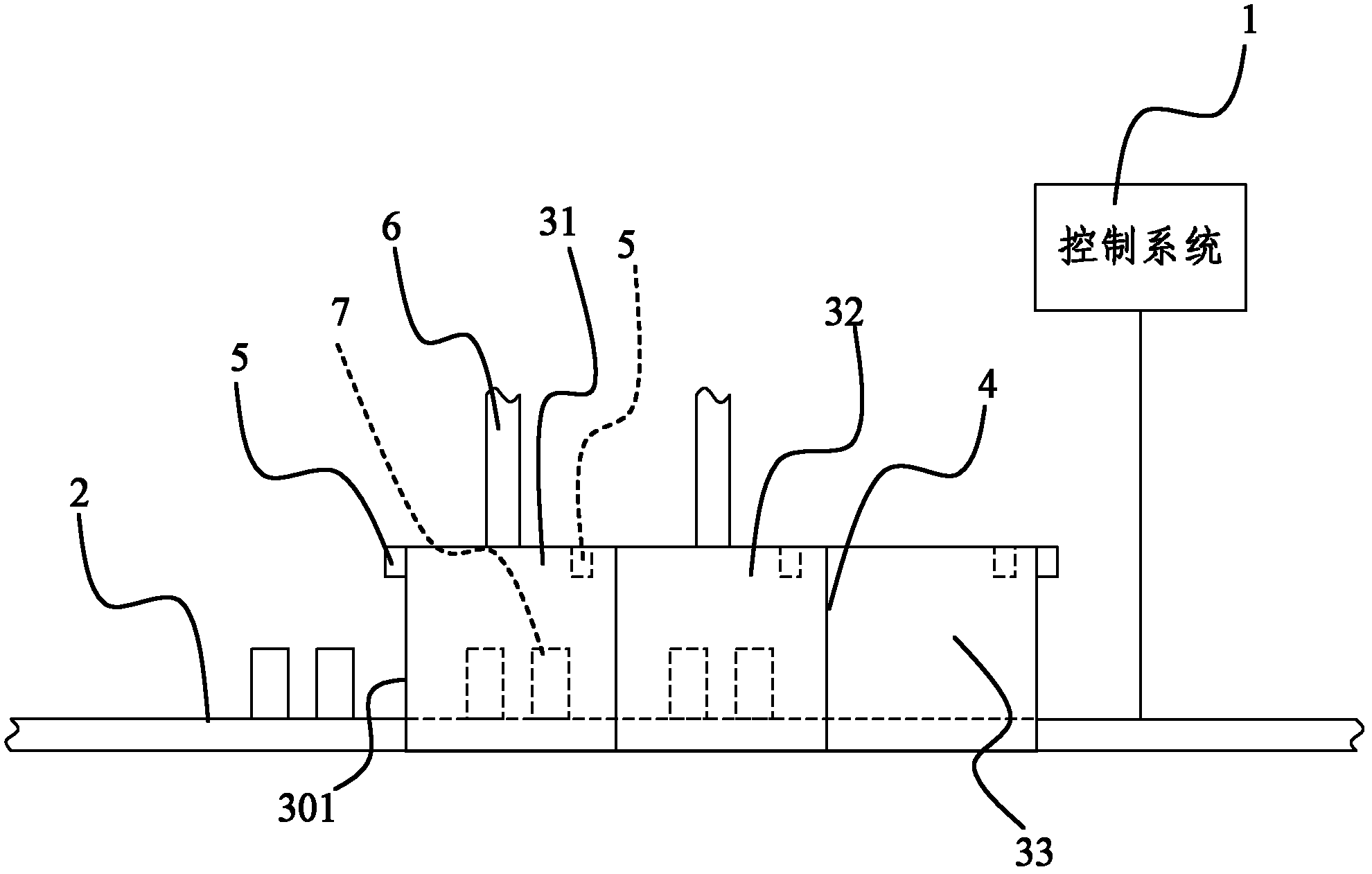

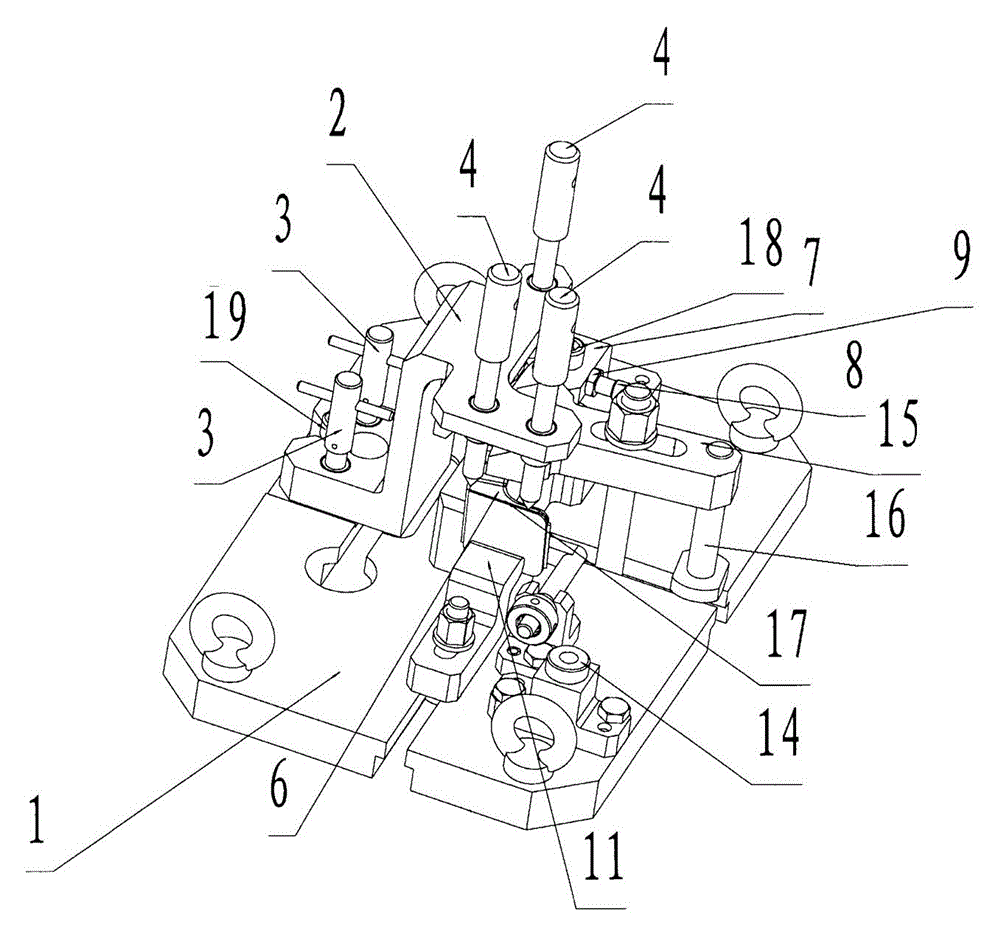

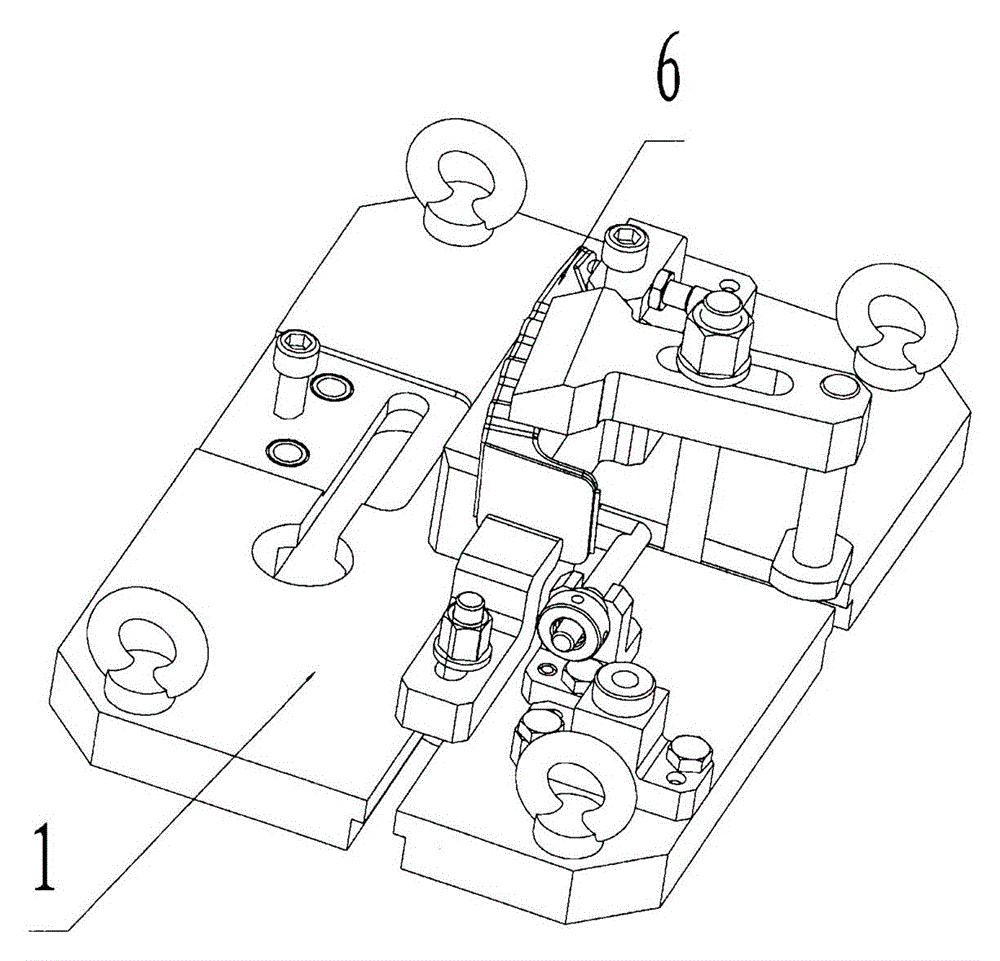

Intelligent glove pinhole detection device

PendingCN111220334AImprove accuracyReduce the risk of non-conformityMeasurement of fluid loss/gain rateMechanical engineeringElectrical and Electronics engineering

The invention discloses an intelligent glove pinhole detection device, and the device comprises a rack and a plurality of detection devices which are sequentially arranged on the rack at intervals. The device is characterized in that each detection device comprises a mounting frame, wherein hollow limiting sleeves are fixedly arranged at the two ends of each mounting frame respectively; each detection device also comprises a detection head and a control device; telescopic detection heads are arranged at the outer ends of the limiting sleeves respectively, and when the detection heads partiallyretract into the limiting sleeves, the limiting sleeves can be sealed with the detection heads making contact with the limiting sleeves; an inflation channel penetrating through the detection head isformed in the detection head, and the inflation device is communicated with the inflation channel; and the control device controls the detection head to act. The detection device can be effectively suitable for hole inspection of different types of glove products, the accuracy of hole inspection is improved, and the risk that the products are unqualified is reduced; performance parameters can beproperly adjusted according to respective product characteristics of enterprises so as to achieve the optimal detection effect.

Owner:SUZHOU COLOR WAY ENTERPRISE DEV

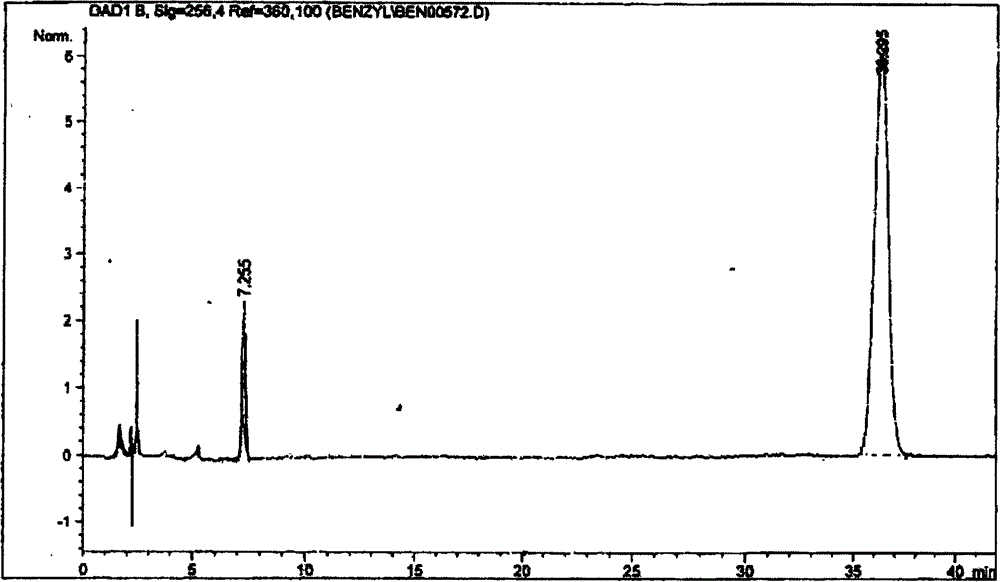

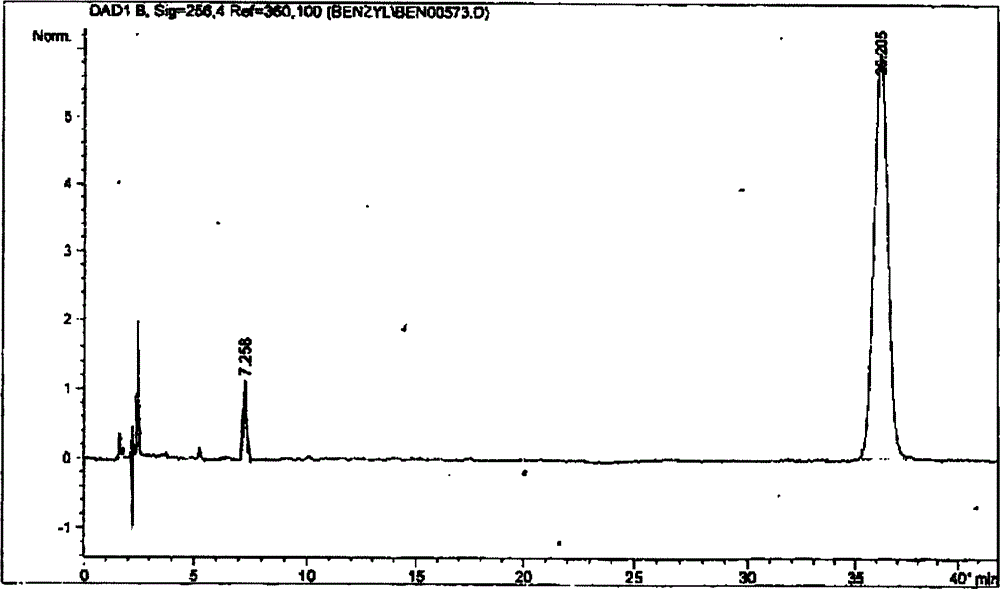

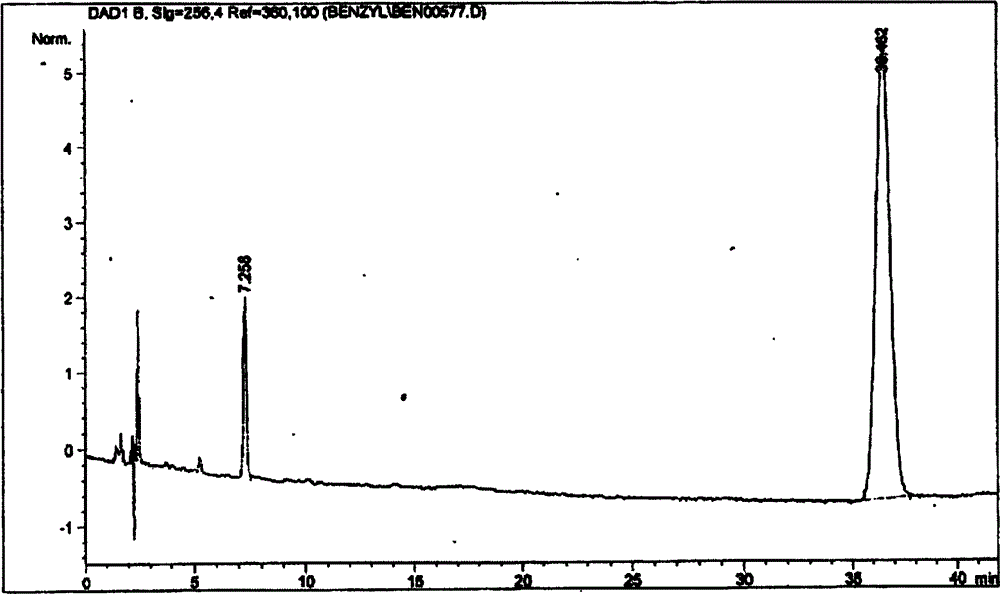

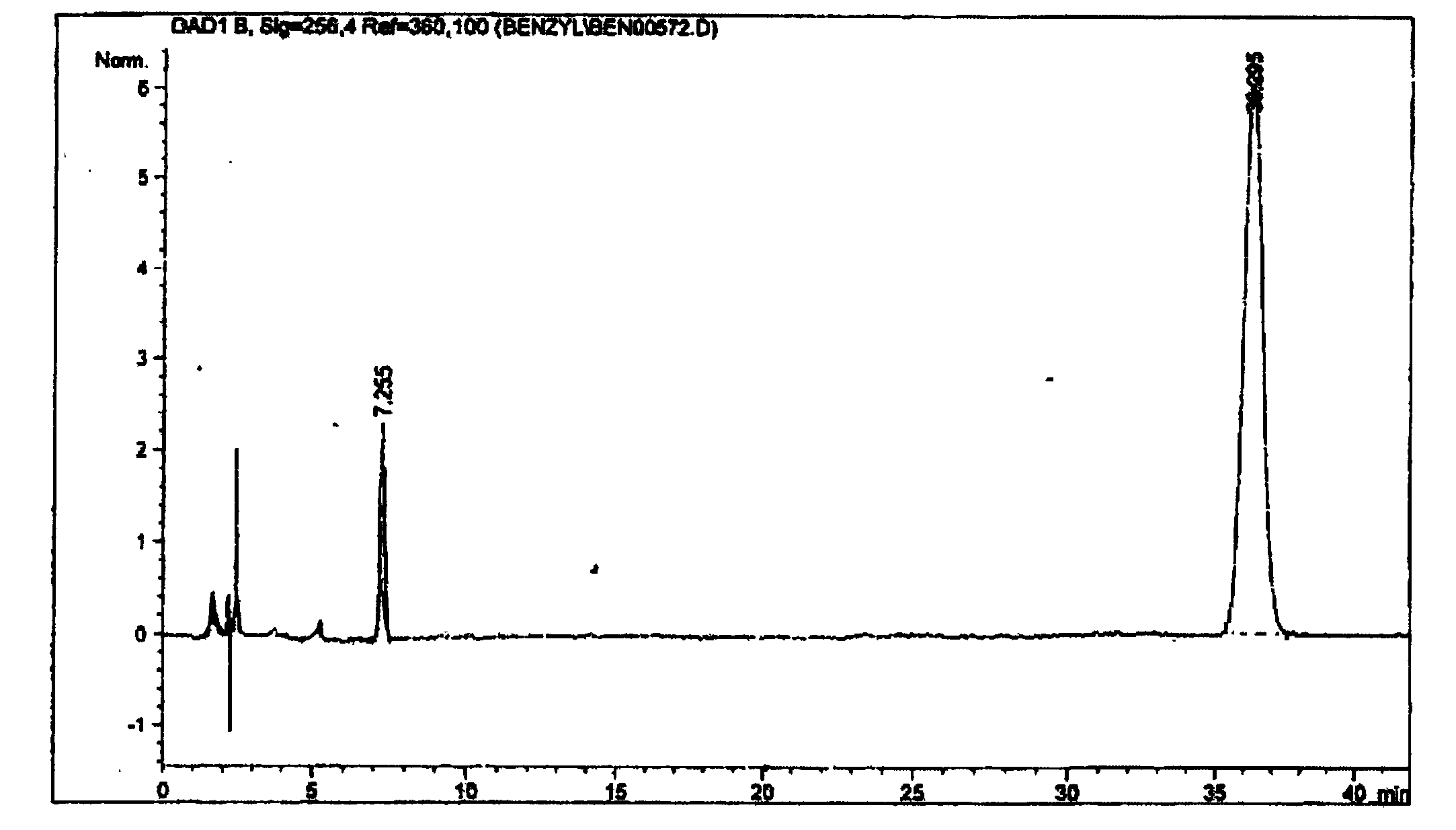

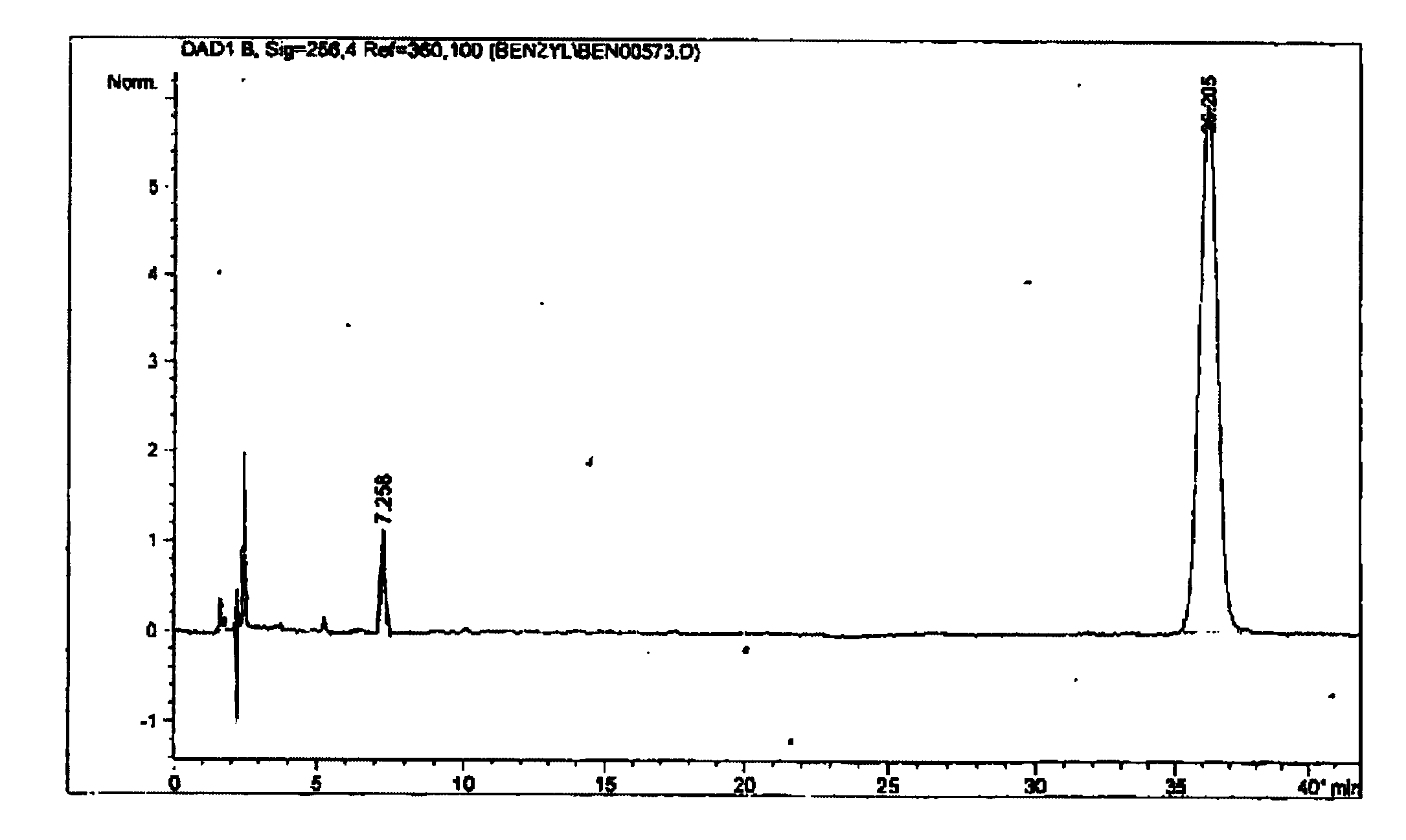

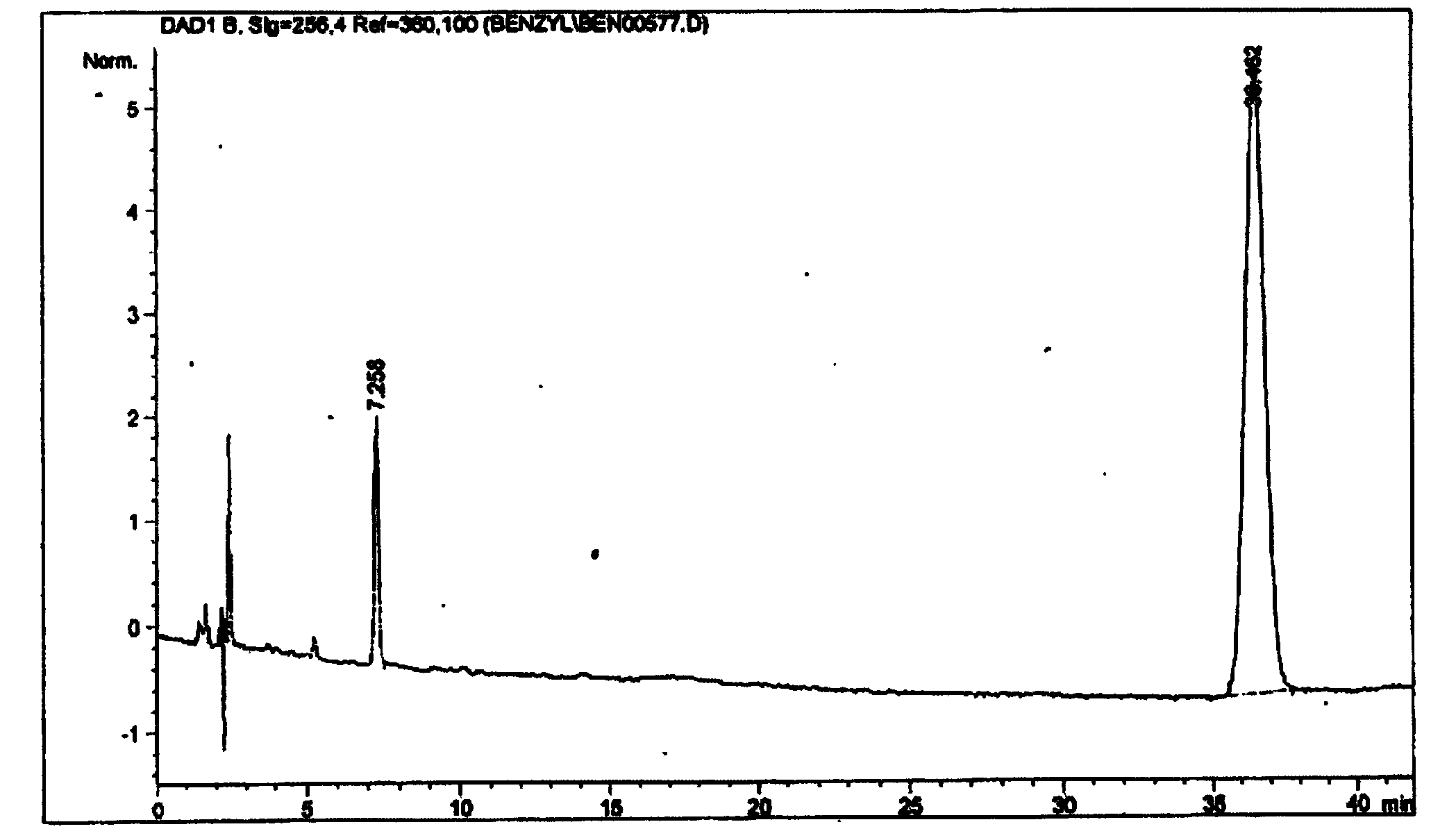

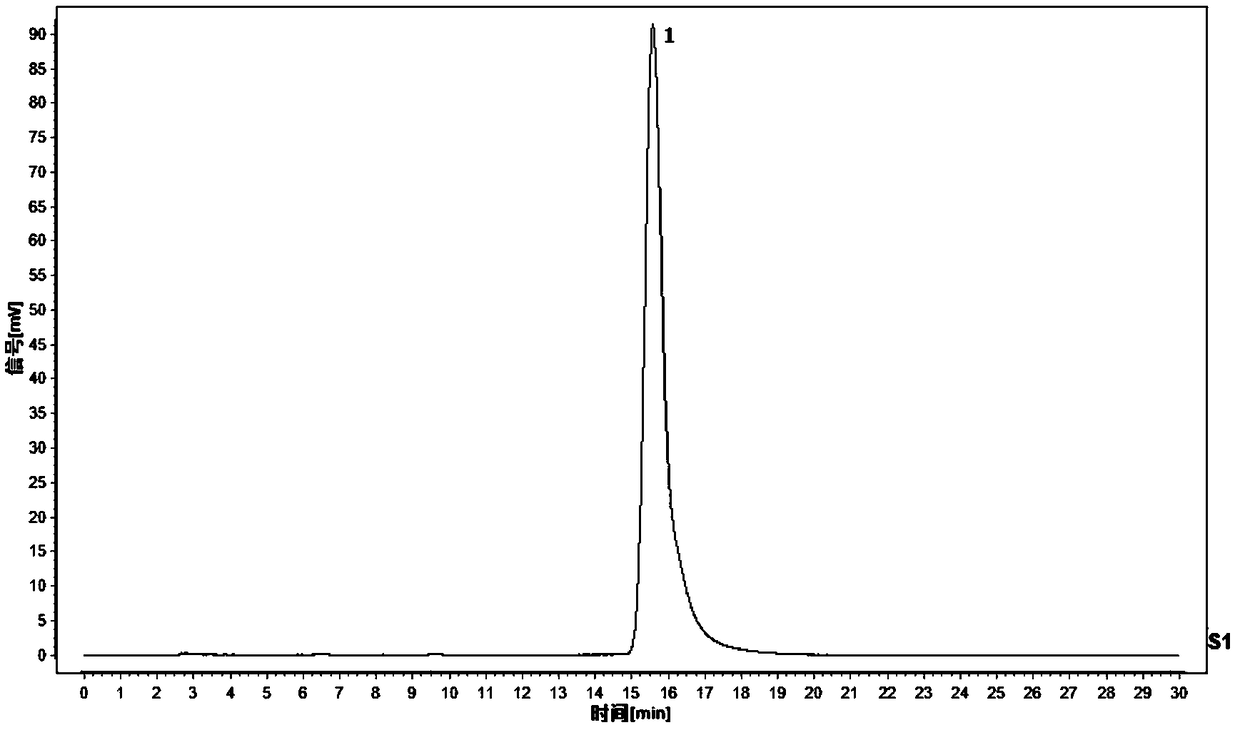

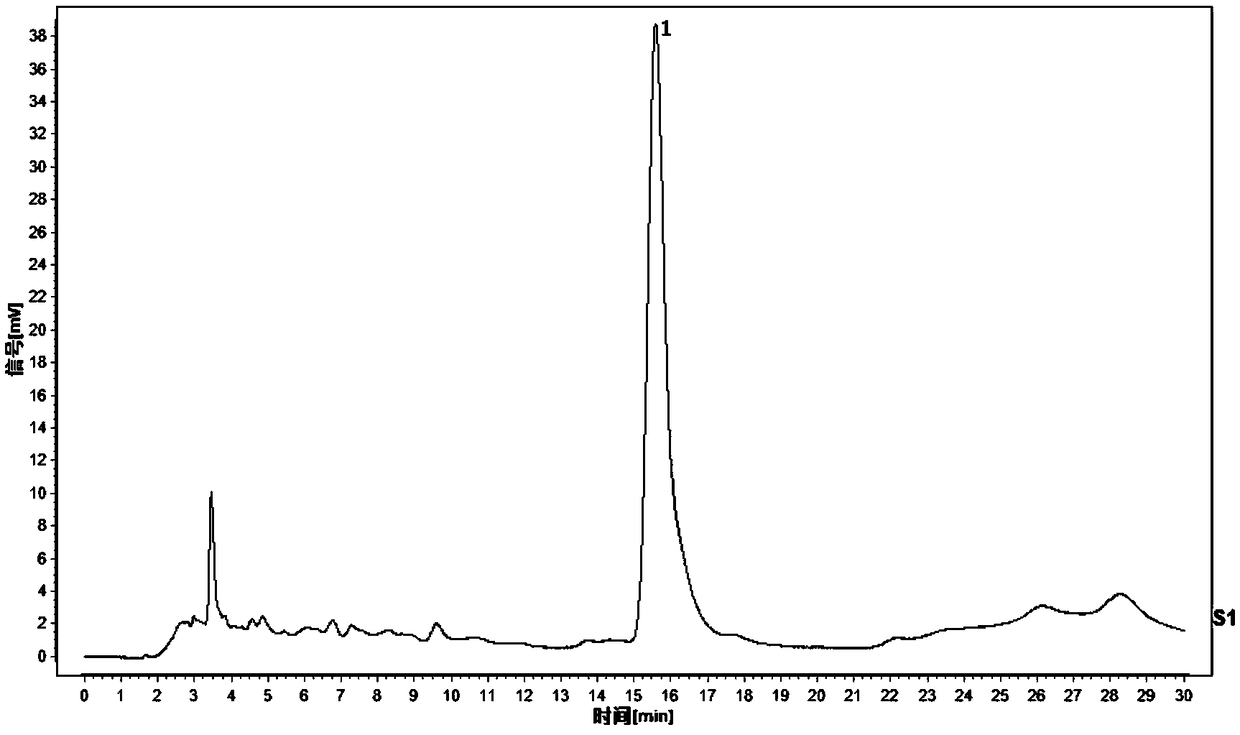

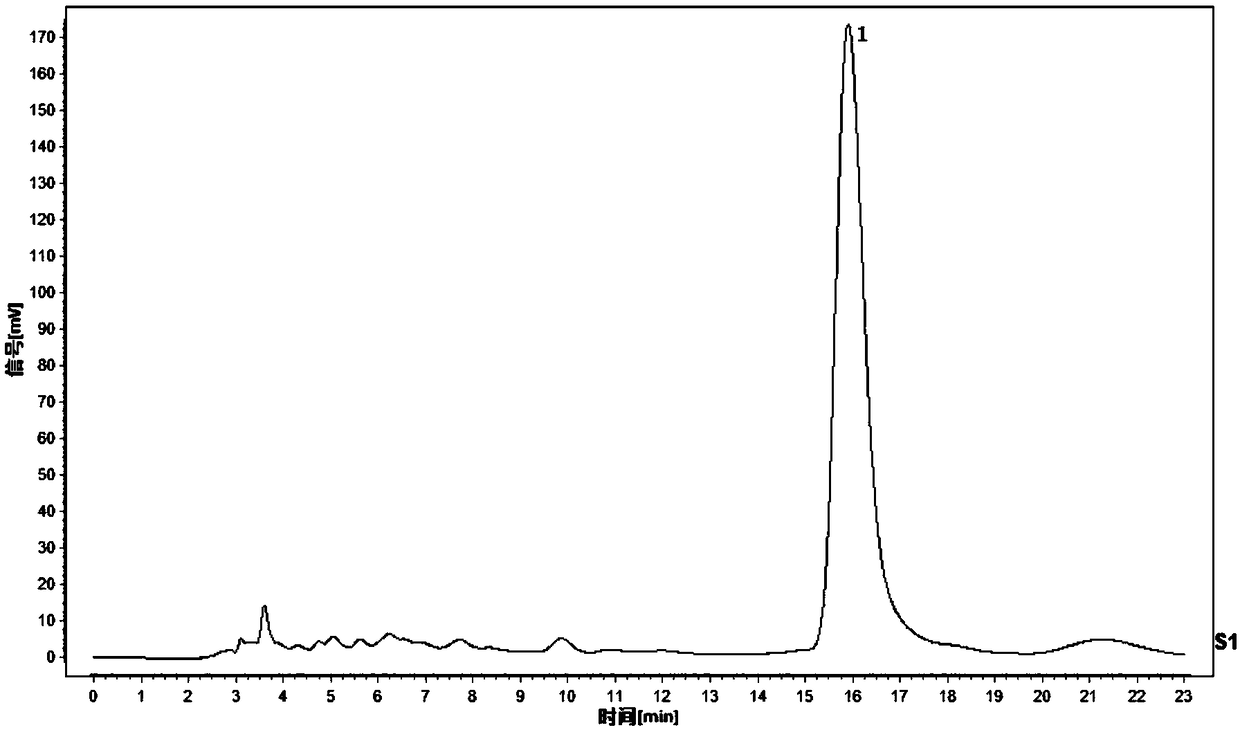

Method for detecting esterification rate of heparin benzyl ester in production process of enoxaparin sodium

ActiveCN103175925BEsterification rate monitoringOvercome unmanageable problemsComponent separationUltraviolet detectorsReversed-Phase Liquid Chromatography

Owner:山东辰龙药业有限公司

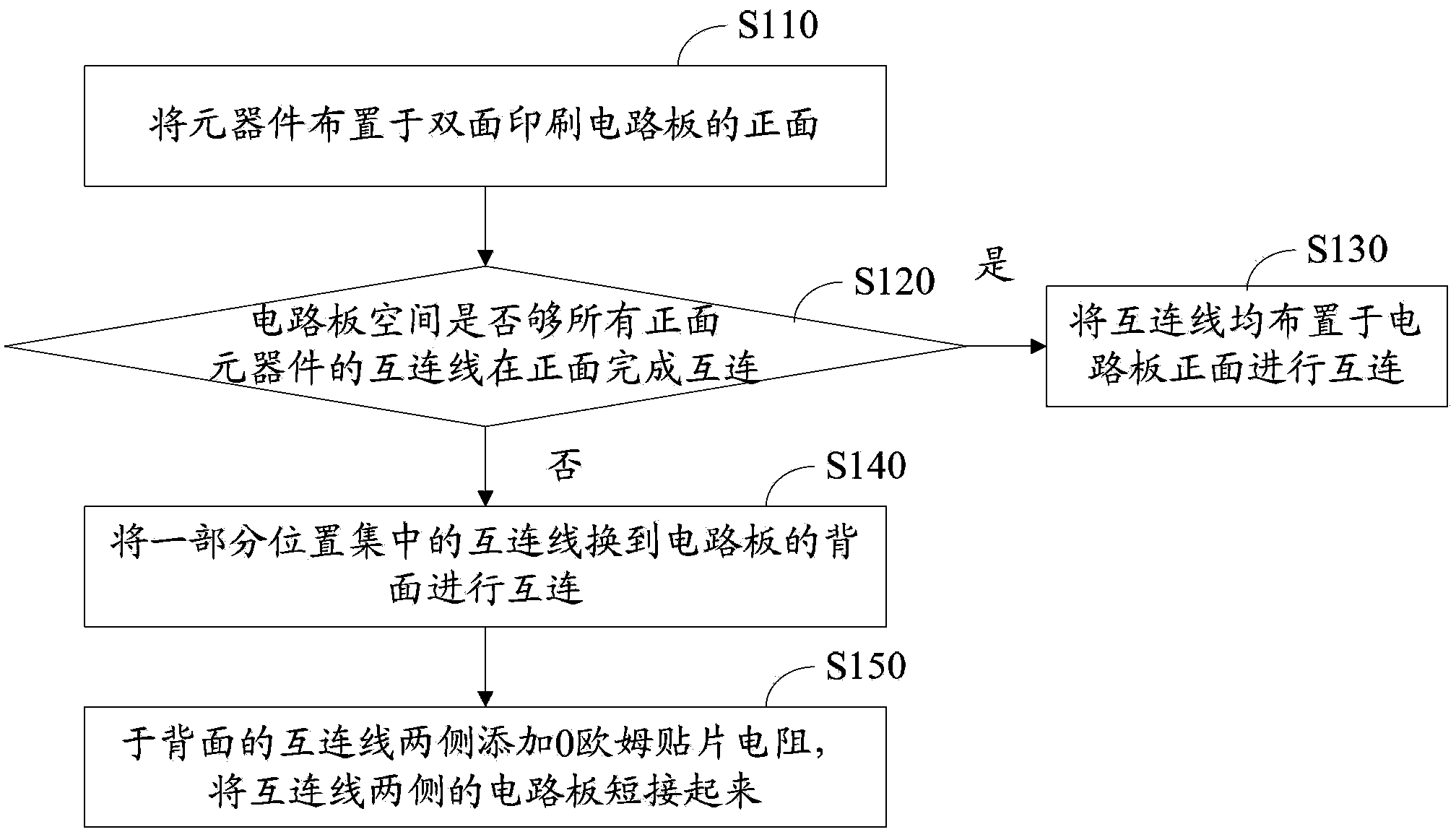

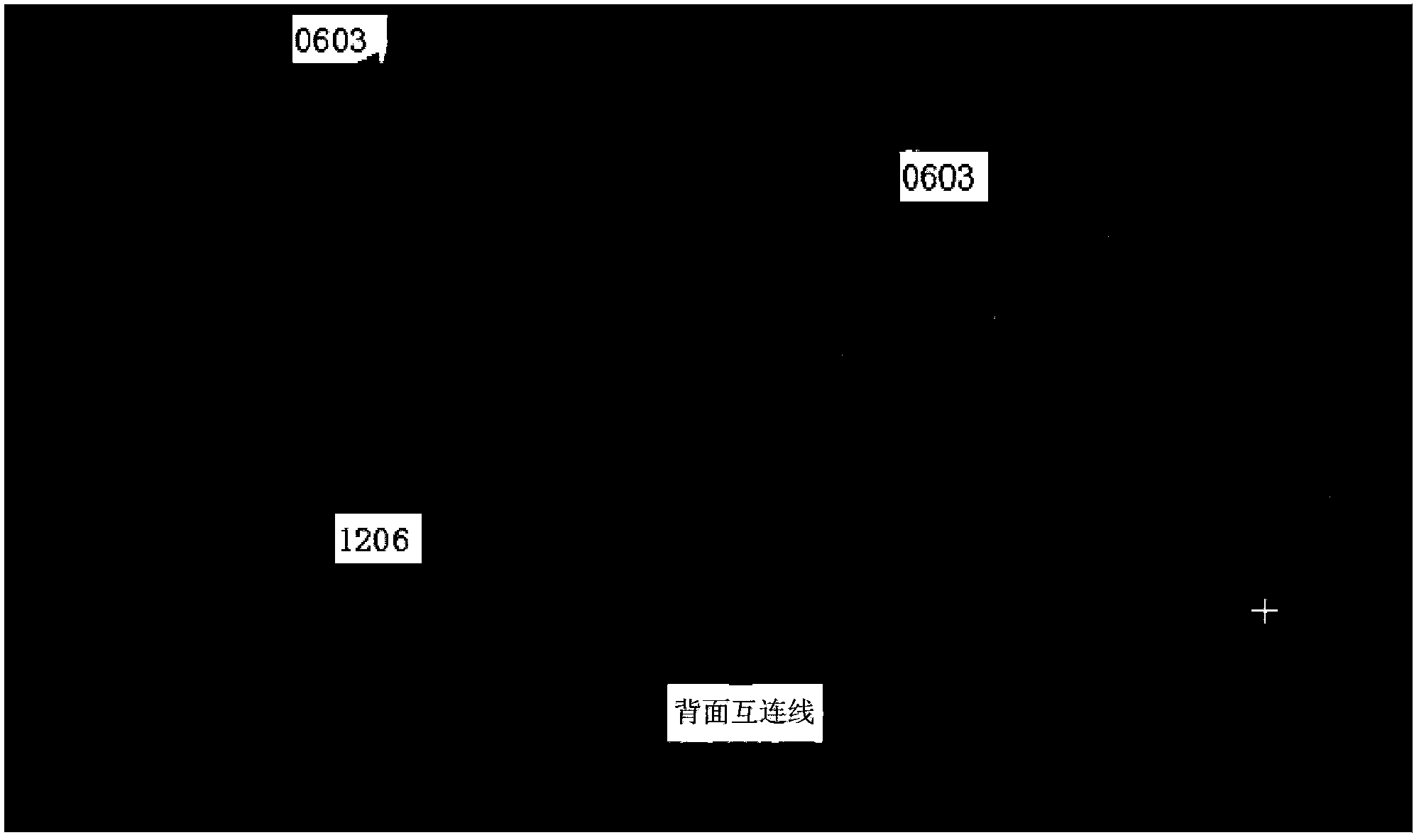

Wiring method for double-face printed circuit board

InactiveCN103889140AReduce the risk of non-conformityReduce defective ratePrinted circuit detailsPrinted circuit non-printed electric components associationElectrical resistance and conductancePrinted circuit board

The invention relates to a wiring method for a double-face printed circuit board. The wiring method comprises steps that: components are arranged at a front face of the double-face printed circuit board; whether the circuit space is enough for mutual connection of mutual connection wires of the components at the front face is determined, if yes, all the mutual connection wires are arranged at the top layer for mutual connection; if not, the partial mutual connection wires which are concentrated at a position are shifted to a back face of the circuit board for mutual connection; two sides of the mutual connection wires at the back face are added with zero Ohm paster resistors, and the circuit boards at two sides of the mutual connection wires are in short connection. According to the wiring method, concentrated layer change of the mutual connection wires needing layer change is carried out, so a relatively-large-area complete plane is acquired at the back face of the double-face printed circuit board, the two zero Ohm resistors are utilized to complete the plane at two sides of the mutual connection wires, the risk of EMC rejection is greatly reduced, the passing percent of three Cs of products and CE authentication is greatly improved by employing the double-face printed circuit board, a reject rate of the products is reduced, and the product market launch speed is effectively improved.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

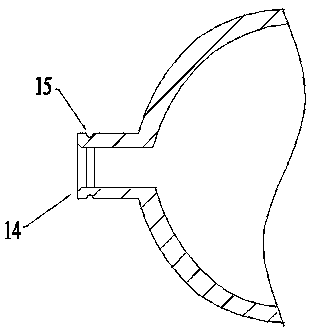

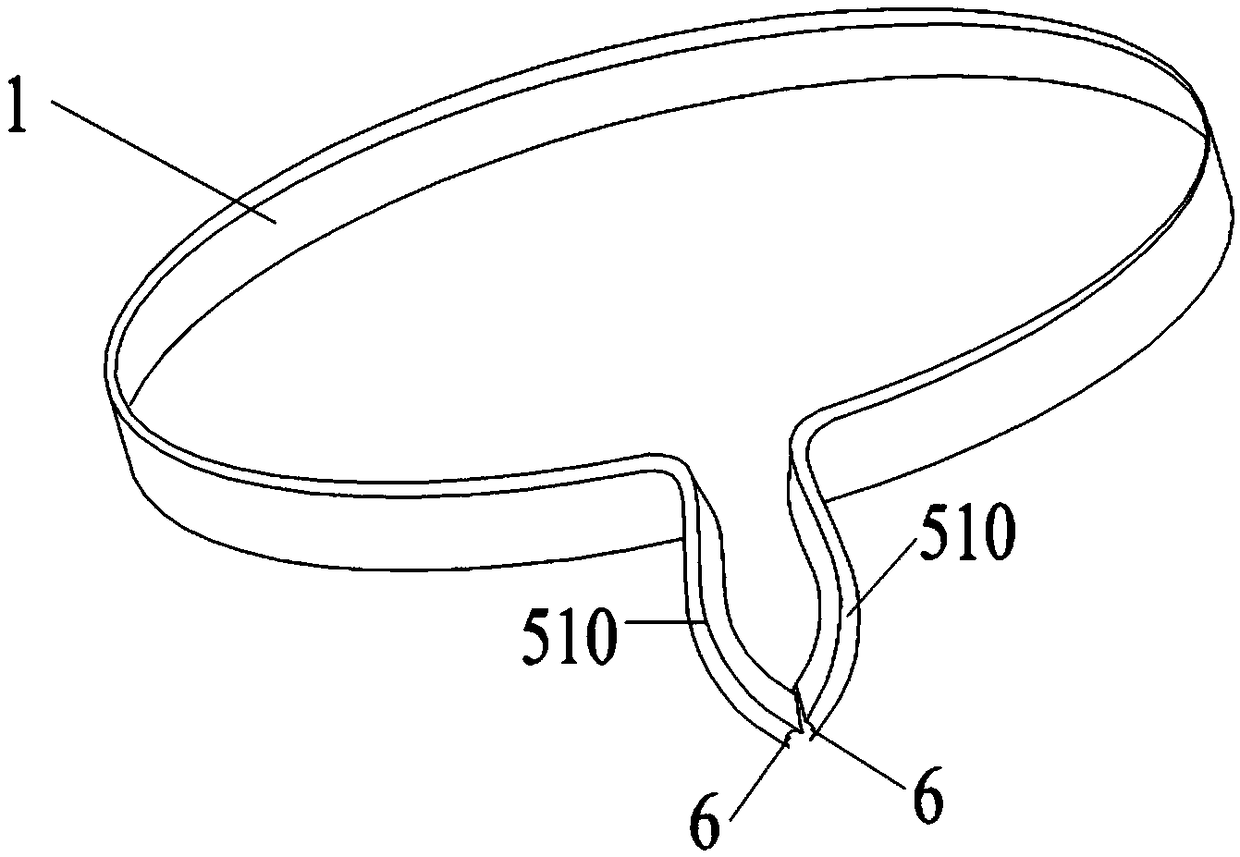

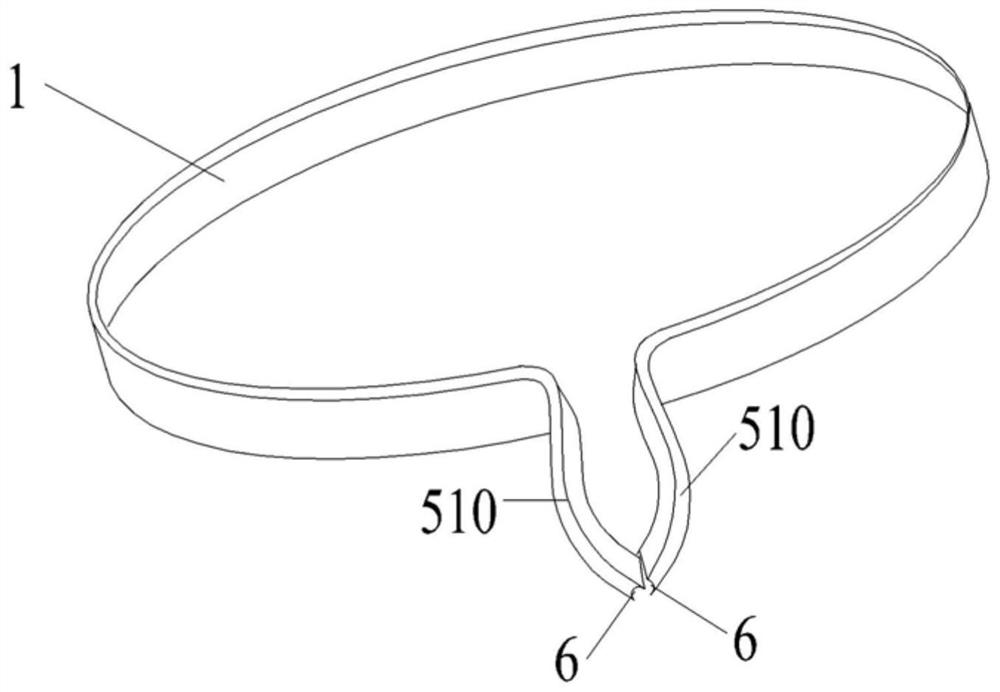

Looped gingival retraction device assembly

The invention relates to the field of medical treatment of oral cavity, in particular to a looped gingival retraction device assembly. The looped gingival retraction device assembly comprises a gingival wire fixing hoop, a gingival wire fixing pipe and a gingival wire fixing plate, wherein both ends of the gingival wire fixing hoop extend down to form fixing jaws, and each fixing jaw is retractedin an arc shape; a gingival wire fixing clip is arranged at one side of the gingival wire fixing pipe, and the gingival wire fixing pipe is fixedly arranged at the end surface of the corresponding fixing jaw. The looped gingival retraction device assembly has the advantage that the gingival wire is firmly pressed into gingival sulcus, so that while the falling of the gingival wire is prevented, the damage to the teeth and gingival is avoided.

Owner:WUXI MENTAL HEALTH CENT

Method for detecting esterification rate of heparin benzyl ester in production process of enoxaparin sodium

ActiveCN103175925AEsterification rate monitoringOvercome unmanageable problemsComponent separationUltraviolet detectorsReversed-Phase Liquid Chromatography

The invention discloses a method for detecting the esterification rate of heparin benzyl ester in a production process of enoxaparin sodium, belonging to the field of biological medicines. According to the method, by adopting a reversed phase liquid chromatography method and using a high-efficiency liquid chromatograph with an ultraviolet detector, phenylcarbinol generated in a process that heparin benzyl ester drops in an alkaline environment is quantitatively detected and the esterification rate of the heparin benzyl ester is reflected, thus the purpose of controlling the quality of the finished product enoxaparin sodium is reached. Compared with the prior art, the method is capable of simply, rapidly and accurately monitoring the esterification rate of the heparin benzyl ester, thereby reducing the unqualified risk of the finished product enoxaparin sodium and the production cost of enterprises, and achieving great good popularization and application value.

Owner:山东辰龙药业有限公司

Method for measuring depth of roller body hardening layer

Owner:BAOSTEEL ROLL SCI & TECH

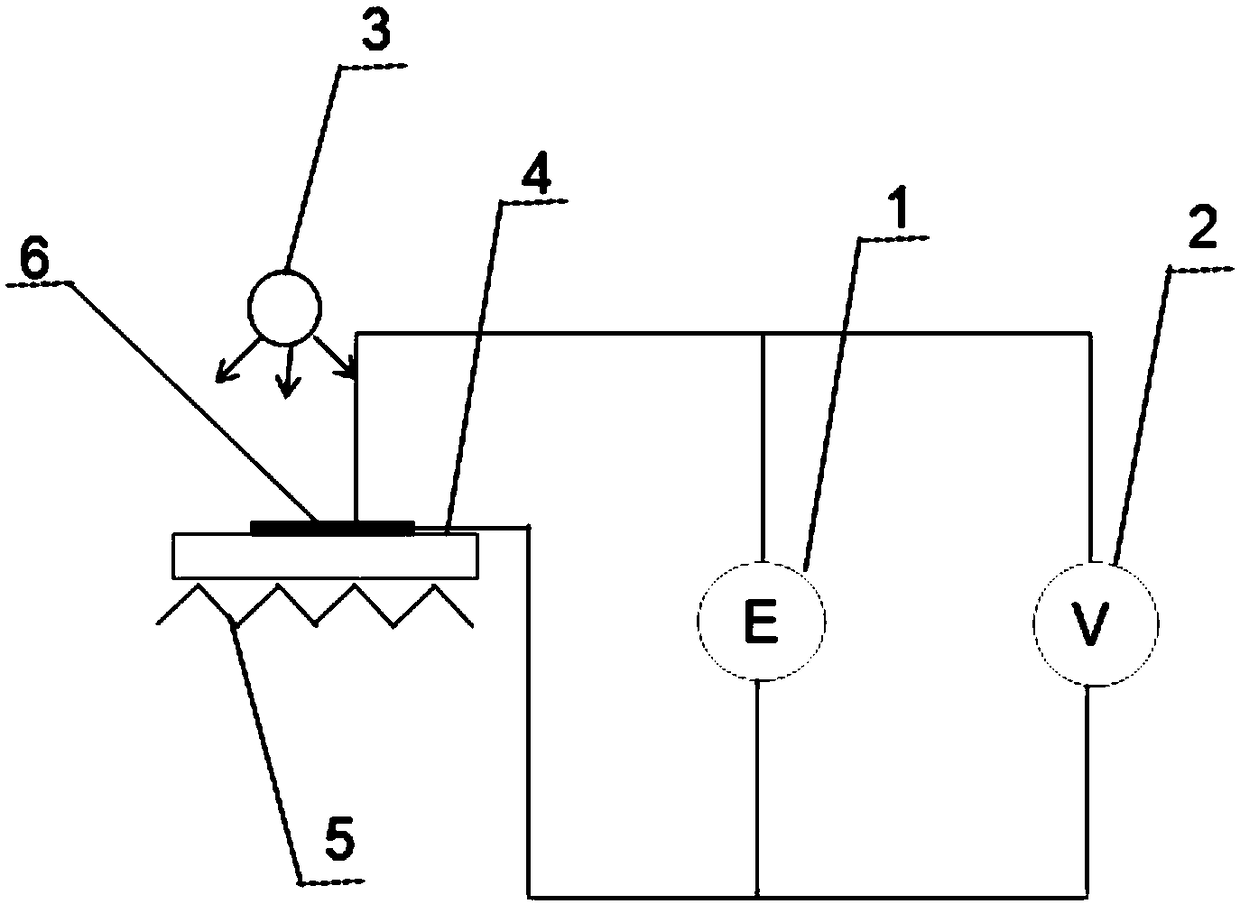

Device and method for detecting light-induced degradation (LID) of crystalline silicon cell

InactiveCN109379045AReduce the risk of non-conformityDoes not affect the production linePhotovoltaic monitoringPhotovoltaic energy generationProduction lineVoltmeter

The invention provides a device and method for detecting the light-induced degradation (LID) of a crystalline silicon cell, and relates to the technical field of crystalline silicon solar cells. The device for detecting the LID of the crystalline silicon cell comprises a placement platform, an illumination simulator, a heating device, a power source, and a voltmeter. The device is simple in structure and can quickly detect whether the LID of the crystalline silicon battery is qualified. The method for detecting the LID of the crystalline silicon cell detects the crystalline silicon cell by using the device for detecting the LID of the crystalline silicon cell. The method can quickly detect whether the LID of the crystalline silicon battery is qualified by one device, does not need a battery cell efficiency tester, does not affect the production of a production line, has simple steps and is convenient to operate, thereby realizing a purpose of monitoring the LID of a battery cell in real time and reducing a risk of qualified battery cell LID in batches.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

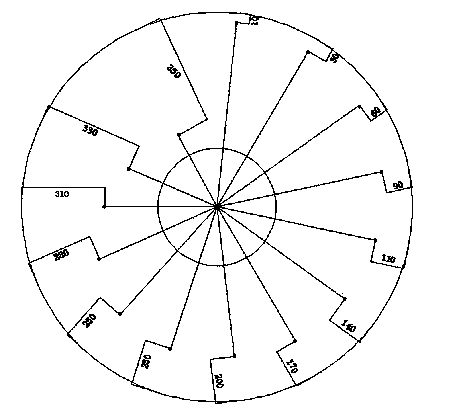

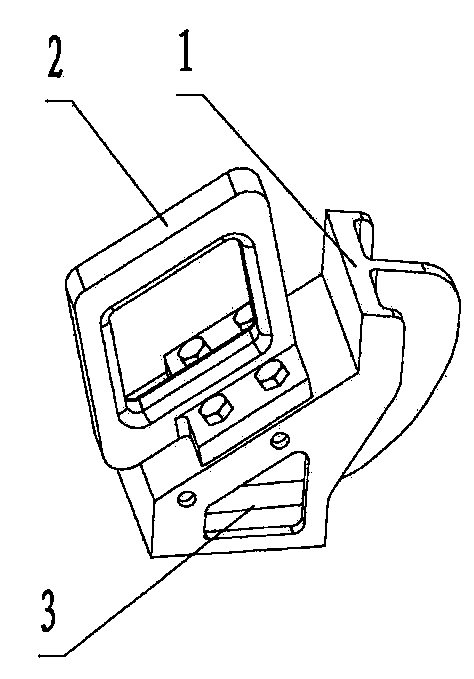

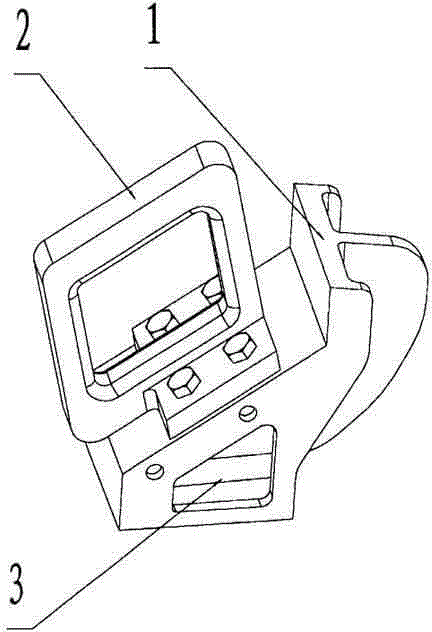

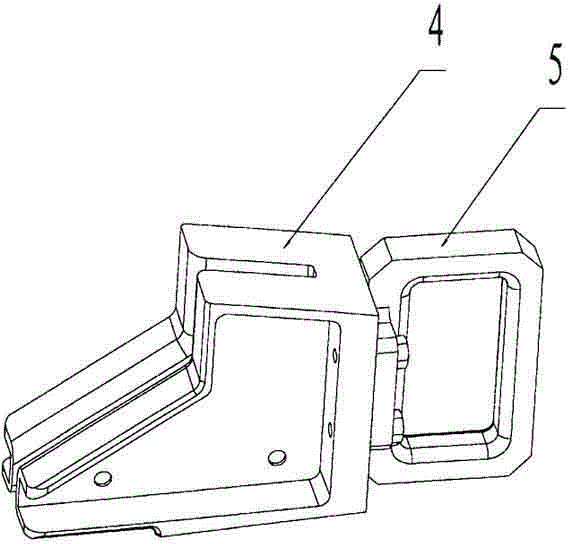

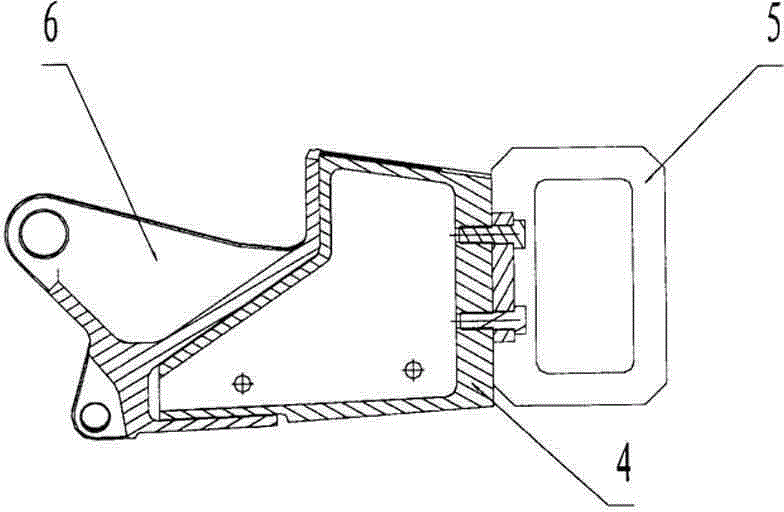

Device and method for interchangeability of aircraft component assembly parts in complex structure

ActiveCN103434657AImprove interchangeabilityImprove assembly efficiencyAircraft assemblyPigmentAirplane

The invention discloses a device and a method for interchangeability of aircraft component assembly parts in complex structures. The device comprises two test blocks, wherein handles is arranged on the test blocks, the structures of the test blocks are identical to the structure at a coordination area position of the aircraft assembling parts, a view window is arranged at a shield position of an assembling matching area; the method comprises the following steps of uniformly coating grinding pigment with color on the surfaces of the test blocks of the aircraft parts and corresponding matching surfaces in the aircraft parts, placing the test blocks in the aircraft parts, testing an inner assembling surface of the aircraft parts, finishing an assembling interference position, and finally satisfying the optional interchangeable assembly of the aircraft parts. The interchangeability of aircraft component assembly parts in complex structures is realized, the assembling efficiency of the aircraft parts is improved, the risk that the aircraft assembly is unqualified is reduced, the cost is low and the practicability is good.

Owner:SHENYANG AIRCRAFT CORP

A device and method for interchangeability of complex structure aircraft parts assembly

ActiveCN103434657BImprove interchangeabilityImprove assembly efficiencyAircraft assemblyPigmentAirplane

The invention discloses a device and a method for interchangeability of aircraft component assembly parts in complex structures. The device comprises two test blocks, wherein handles is arranged on the test blocks, the structures of the test blocks are identical to the structure at a coordination area position of the aircraft assembling parts, a view window is arranged at a shield position of an assembling matching area; the method comprises the following steps of uniformly coating grinding pigment with color on the surfaces of the test blocks of the aircraft parts and corresponding matching surfaces in the aircraft parts, placing the test blocks in the aircraft parts, testing an inner assembling surface of the aircraft parts, finishing an assembling interference position, and finally satisfying the optional interchangeable assembly of the aircraft parts. The interchangeability of aircraft component assembly parts in complex structures is realized, the assembling efficiency of the aircraft parts is improved, the risk that the aircraft assembly is unqualified is reduced, the cost is low and the practicability is good.

Owner:SHENYANG AIRCRAFT CORP

A wire loop gingival retractor assembly

ActiveCN108814741BFixed and accurateNot easy to come outImpression capsGingival grooveGingival space

The invention relates to the field of medical treatment of oral cavity, in particular to a looped gingival retraction device assembly. The looped gingival retraction device assembly comprises a gingival wire fixing hoop, a gingival wire fixing pipe and a gingival wire fixing plate, wherein both ends of the gingival wire fixing hoop extend down to form fixing jaws, and each fixing jaw is retractedin an arc shape; a gingival wire fixing clip is arranged at one side of the gingival wire fixing pipe, and the gingival wire fixing pipe is fixedly arranged at the end surface of the corresponding fixing jaw. The looped gingival retraction device assembly has the advantage that the gingival wire is firmly pressed into gingival sulcus, so that while the falling of the gingival wire is prevented, the damage to the teeth and gingival is avoided.

Owner:WUXI MENTAL HEALTH CENT

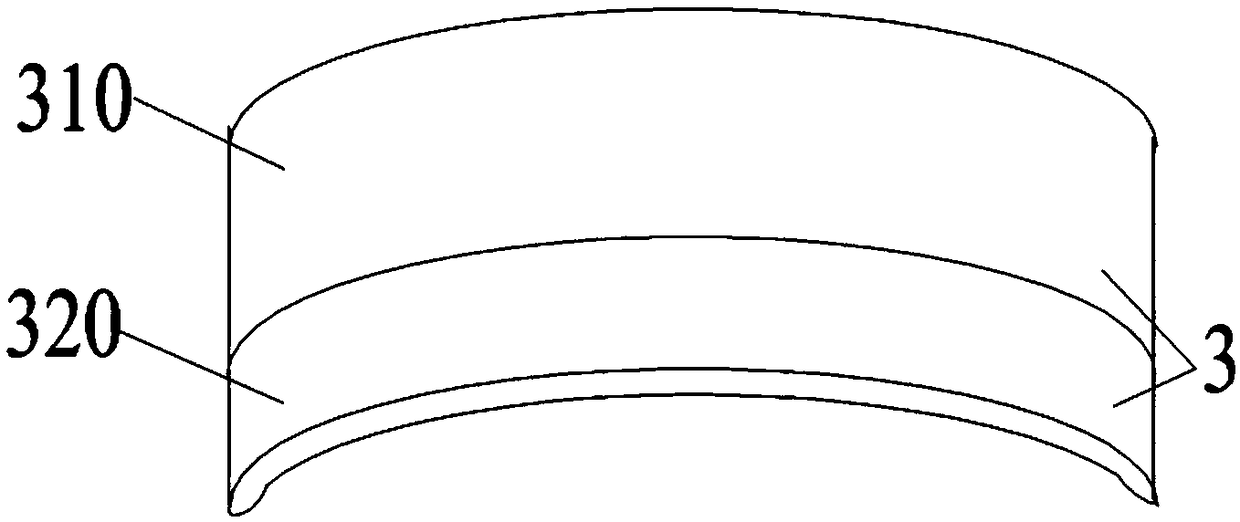

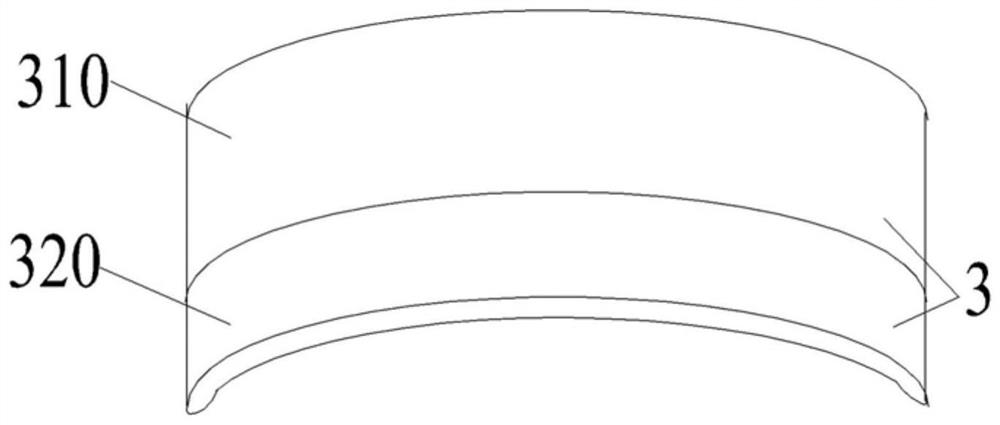

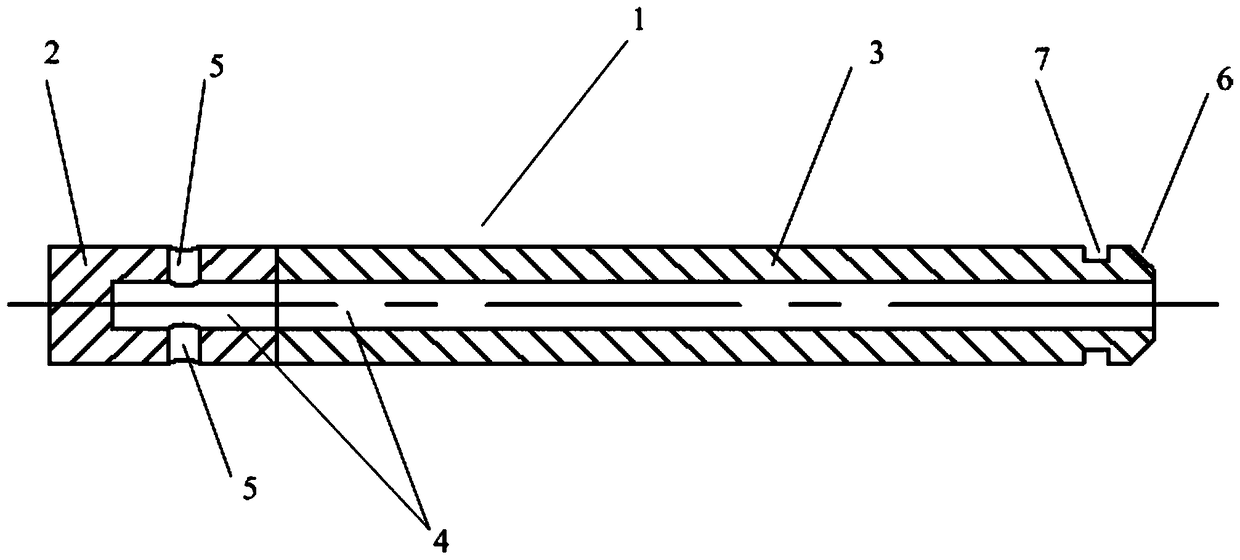

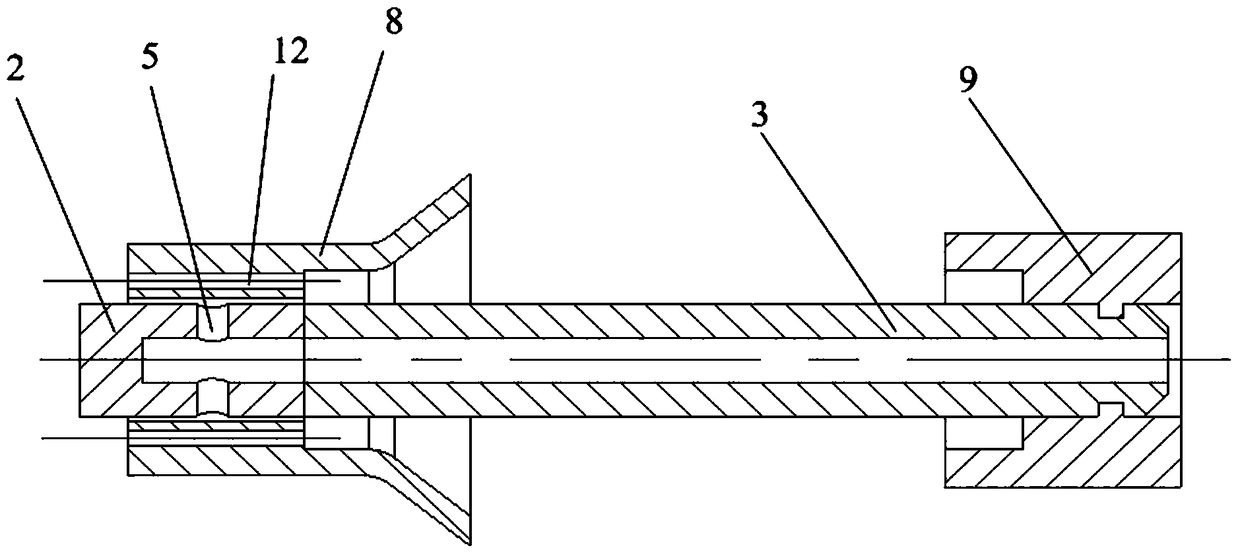

A rubber hose vulcanization mold core and its mold

The present invention discloses a rubber pipe vulcanization mold core and a rubber pipe vulcanization mold, and relates to the technical field of molds. The rubber pipe vulcanization mold core comprises a fixation portion and a molding portion, wherein the fixation portion and the molding portion are connected and fixed, a ventilation hole is arranged inside the mold core along an axial line position, the ventilation hole part positioned on the fixation portion is a blind hole, the ventilation hole part positioned on the molding portion is a through hole, at least a gas inlet hole is arranged on the fixation portion of the mold core, and the outer surface of the fixation portion and the ventilation hole are communicated through the gas inlet hole. The present invention further discloses a mold matched with the mold core, wherein the mold comprises the mold core and a mold sleeve, and the mold sleeve is sleeved on both ends of the mold core. With the rubber pipe vulcanization mold core and the rubber pipe vulcanization mold of the present invention, the problems of low product qualification rate, waste of labor and waste of materials of the existing rubber pipe vulcanization mold core production are solved.

Owner:ANHUI ZHONGDING HOSE PROD

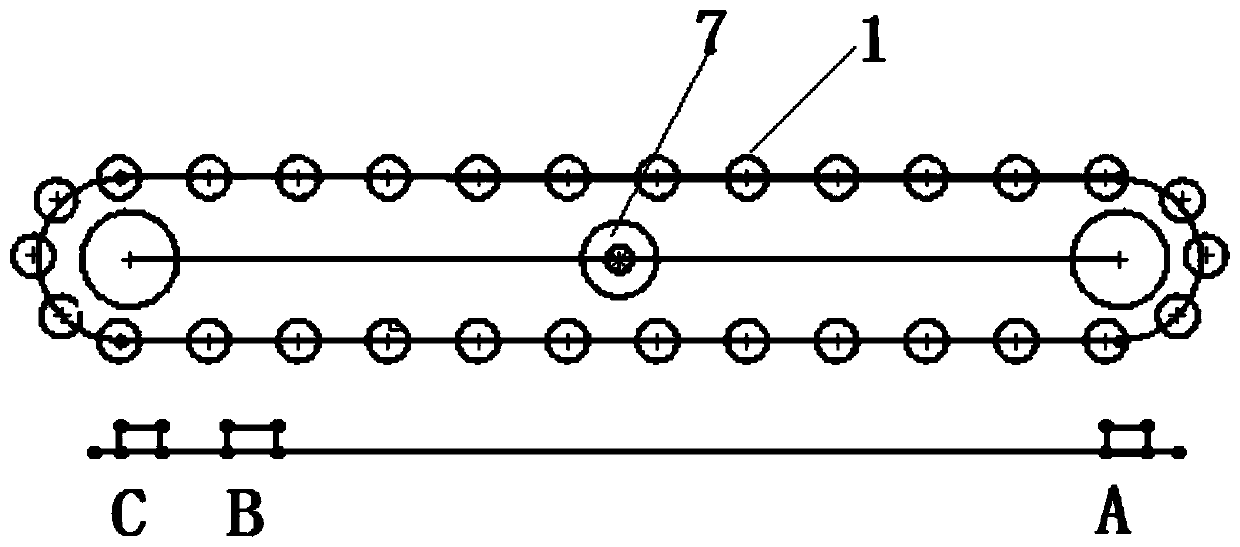

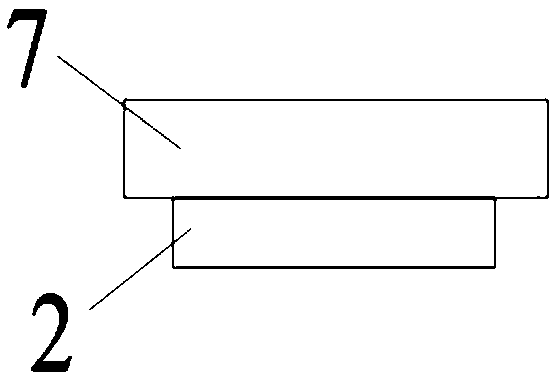

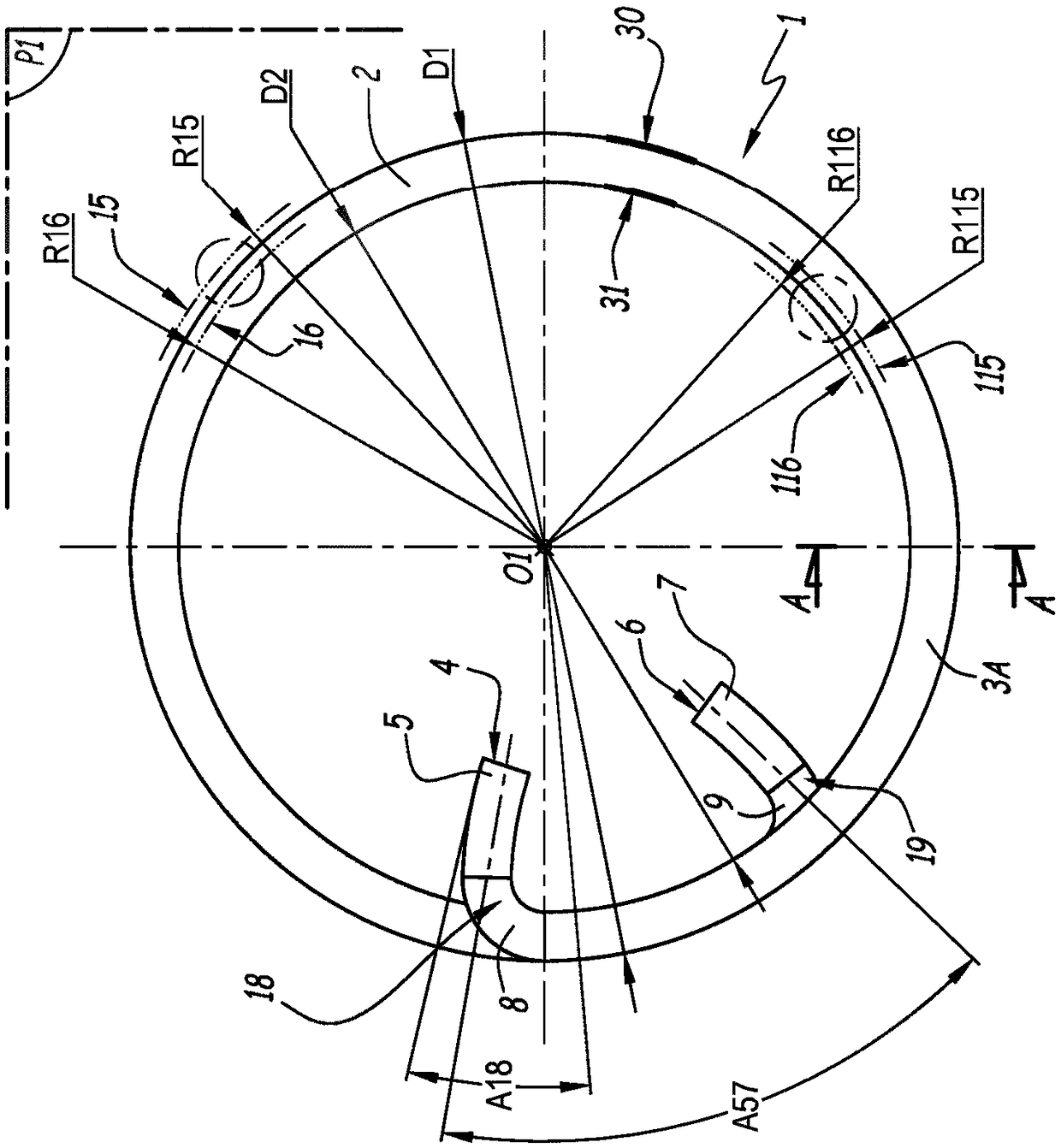

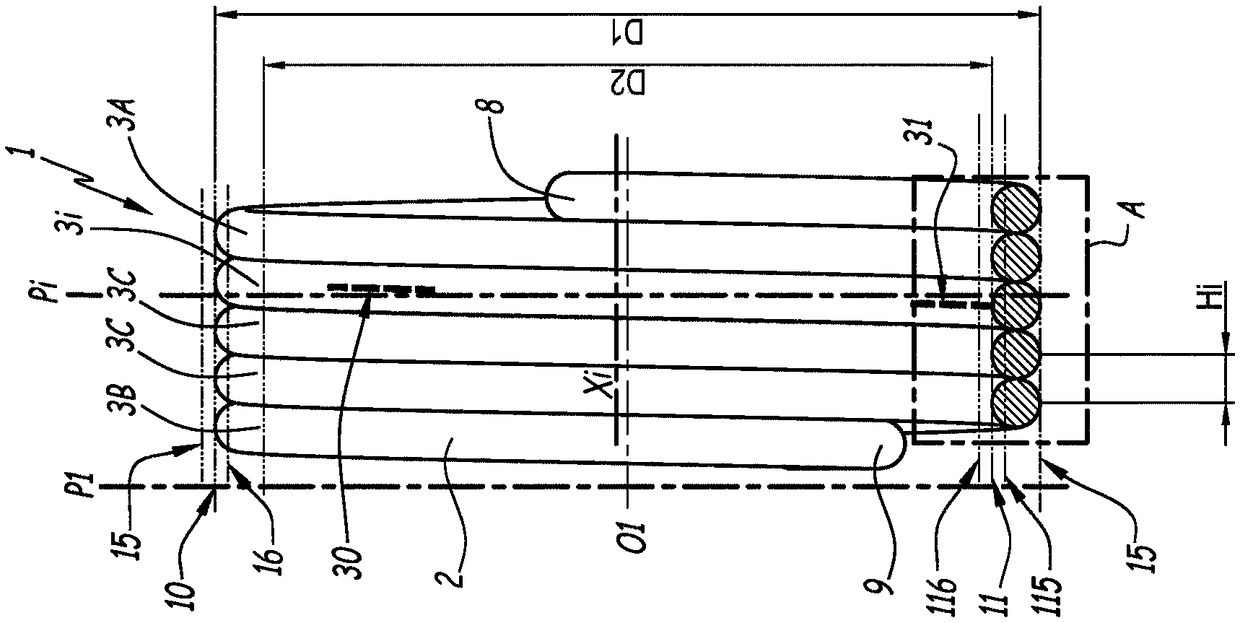

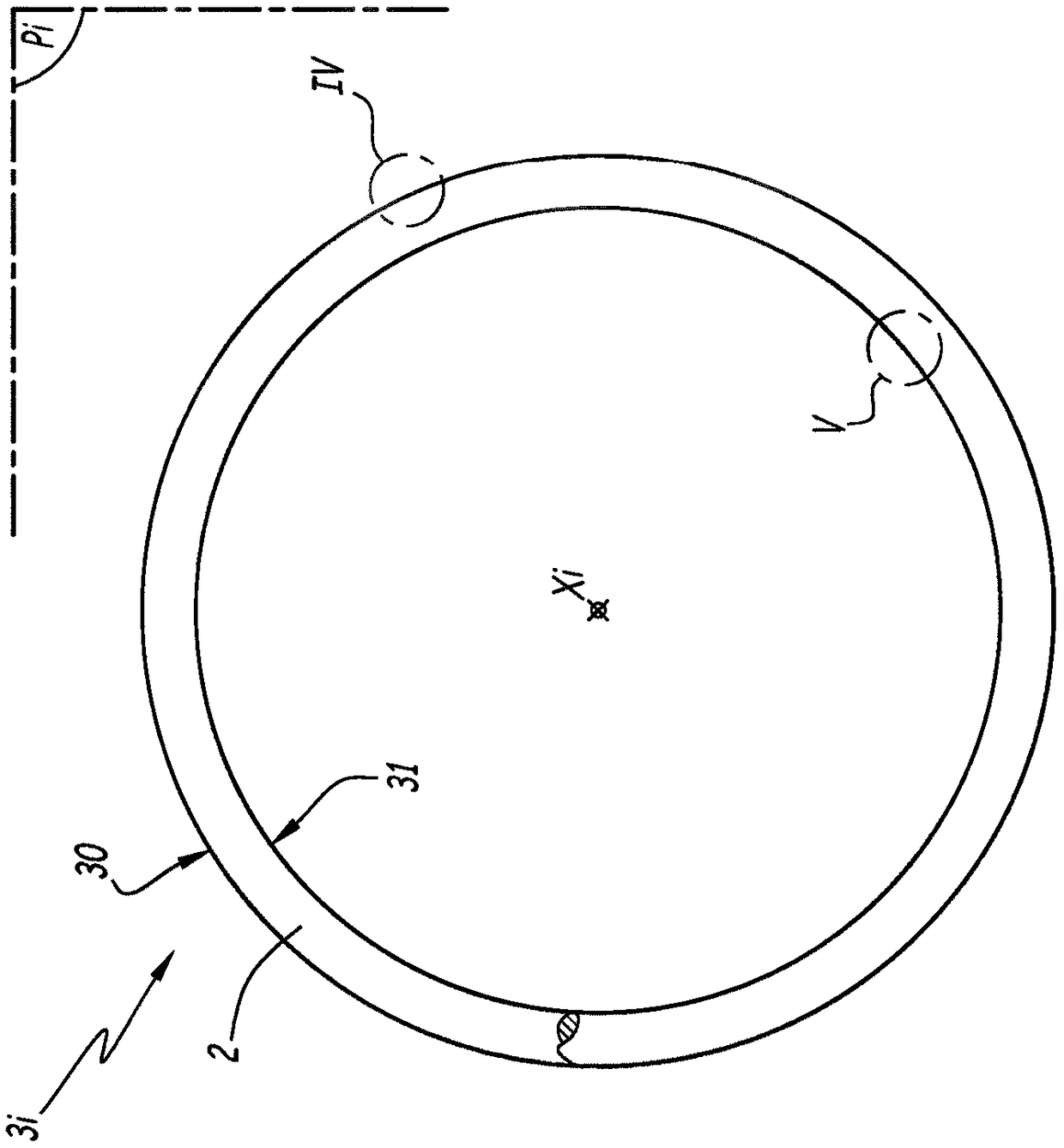

Methods for manufacturing a spring, a spring brake, and a spring brake comprising a spring

ActiveCN109153065AReduce the risk of non-conformityDoor/window protective devicesWire springsEngineeringMechanical engineering

The invention concerns a method for manufacturing a spring (1) for a spring brake (14), comprising a shaping and cutting step f) comprising the following sub-steps: - f1) shaping a raw wire into a coil with a plurality of raw turns, the raw wire having: raw portions that extend from the end of the raw wire over at least one raw turn, and an intermediate portion between the raw portions, - f2) separating the first raw portion and the second raw portion of the raw wire by cutting, after implementing sub-step f1), and - f3) shaping a first tab (5), at a first end of the intermediate portion, after sub-step f1), and - f4) shaping a second tab (7), at a second end of the intermediate portion opposite the first end, after sub-step f1).

Owner:SOMFY ACTIVITES SA

Automatic steam curing system of pipe segment production line

ActiveCN102615704BRealize automatic steamingIncrease productivityCeramic shaping apparatusProduction lineControl system

The invention discloses an automatic steam curing system of a pipe segment production line. The automatic steam curing system comprises a control system and a box body erected at the periphery of a conveyor belt; the box body is divided into a heating chamber, a constant-temperature chamber and a cooling chamber by four openable heat-insulating layers along the motion direction of the conveyor belt; and the heating chamber, the constant-temperature chamber and the cooling chamber are internally and respectively provided with a temperature sensor; the heating chamber and the constant-temperature chamber are further communicated with a steam pipeline which is provided with a steam valve; and the control system is electrically connected with the temperature sensors, the steam valve and the conveyor belt. With adoption of the automatic steam curing system of the pipe segment production line disclosed by the invention, the automatic steam curing of the pipe segment production line is realized; and the automatic steam curing system has the features of high degree of automation, energy-saving and consumption-reducing performances, strong traceability and high efficiency of pipe segment production.

Owner:SHANGHAI TUNNEL ENG CO LTD

Extraction method suitable for water-soluble heat-sensitive ingredients of traditional Chinese medicines

InactiveCN109331053AReduce lossesReduce the risk of non-conformityPlant ingredientsMicroorganismMedicinal herbs

Owner:SHINEWAY PHARMA GRP LTD

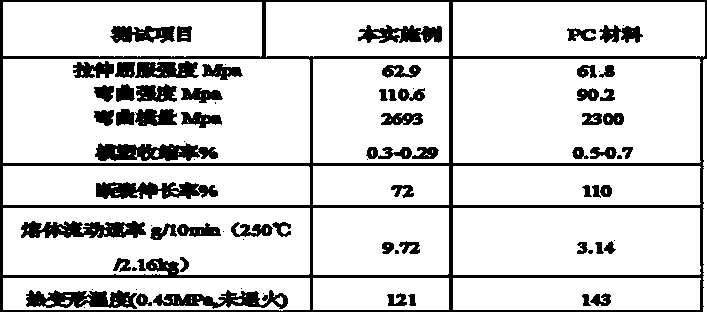

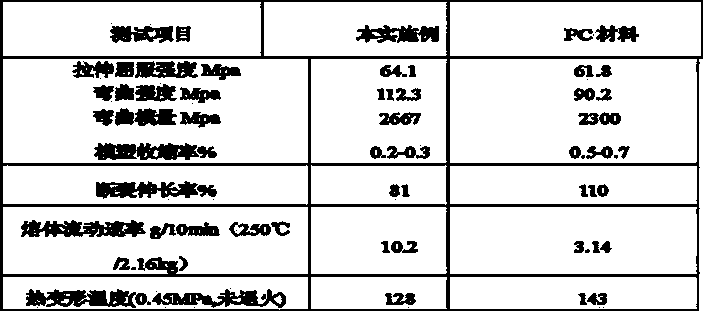

High-melt-index PC composite material for 3D printing and preparation method thereof

InactiveCN111484716AGuaranteed mechanical propertiesIncreased melt flow rateAdditive manufacturing apparatusCyclohexanedimethanolTrans esterification

The invention discloses a high-melt-index PC composite material for 3D printing and a preparation method thereof. The high-melt-index PC composite material is composed of the following components in parts by weight: 65 to 85 parts of PC, 15 to 35 parts of PETG, 2 to 5 parts of a compatilizer, 0.2 to 0.5 part of an antioxidant, and 0.3 to 1 part of a lubricant. A PETG material is added into a PC material; under the action of high temperature and shearing force, ester exchange reaction and chain slip diffusion are carried out between 1,4-cyclohexanedimethanol ester and polycarbonate; the molecular weight distribution of the PC material is widened, the acting force between molecular chains is weakened, the melt flow rate of the material is increased, the printing temperature of the PC consumable is reduced to about 250 DEG C, and the printing temperature range of a conventional FDM 3D printer is met. The internal stress of the material system is weakened, so that the warping phenomenon ofthe PC3D printing consumable product is obviously improved.

Owner:四川鑫达企业集团有限公司

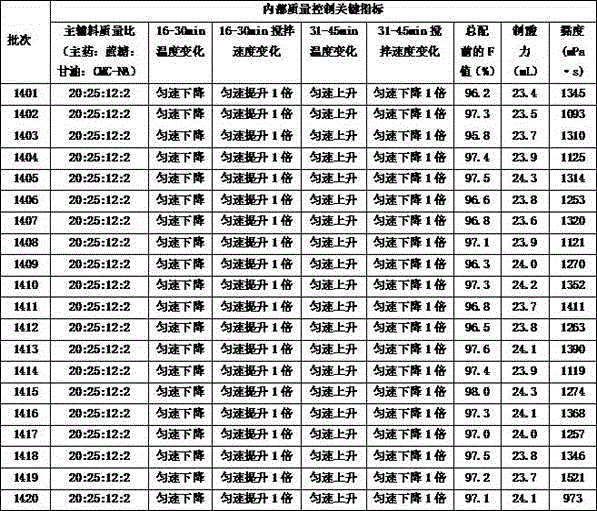

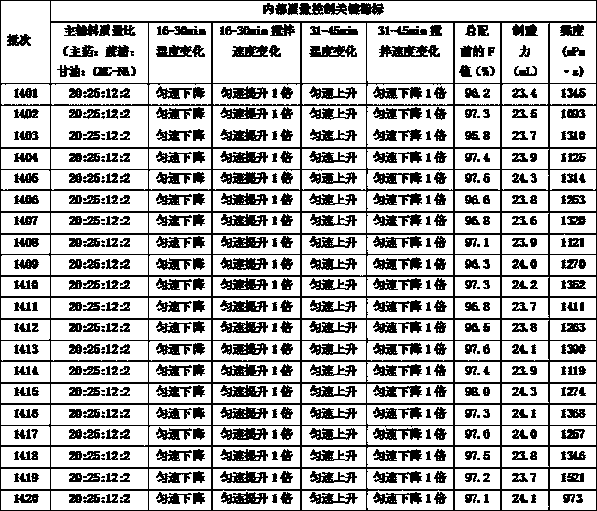

Quality control method of almagate suspension

ActiveCN105911057AReduce the risk of non-conformityGuarantee safe and effectiveMaterial analysis by observing effect on chemical indicatorFlow propertiesChemistryQuality control

The invention relates to a quality control method of an almagate suspension, and the method is easy and convenient to operate. The method comprises the steps of (1), quality control of a suspension phase: the sedimentation volume ratio F is measured, and the F should be larger than or equal to 95.0%; (2) quality control before filling: absorption of acid is measured, the consumption of each 1g of almagate suspension on a hydrochloric acid volumetric solution (0.1 mol / L) should be larger than or equal to 23.0 mL; viscosity is measured, and the measured viscosity coefficient eta should be 1,200+-400 mPa.s. The preparation process of the almagate suspension is subjected to quality control with the method, preventive measures are taken in advance, the rick of unqualified finished products is reduced greatly, and clinical medicine is ensured to be safe and effective.

Owner:YANGZHOU YIYANG PHARMA

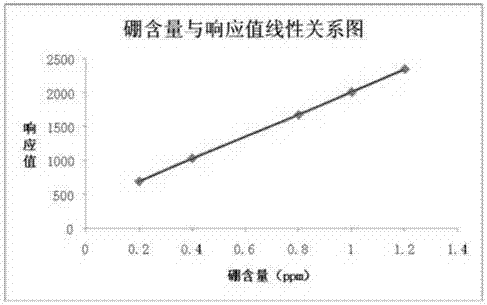

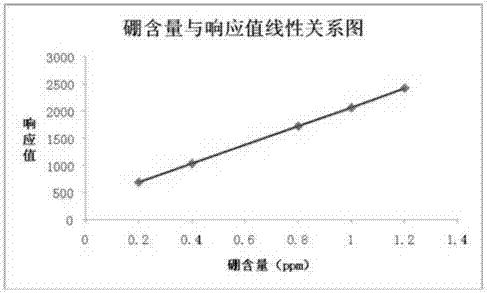

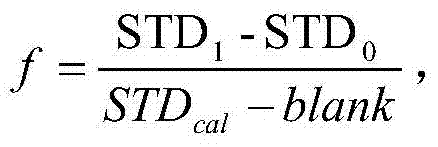

Detection method of boron content in the production process of dalteparin sodium

ActiveCN104535558BAccurate detectionOvercome unqualified problemsAnalysis by thermal excitationData treatmentUltimate tensile strength

The invention discloses a method for detecting the content of boron in a dalteparin sodium production process, belonging to the field of biological medicines. The method disclosed by the invention comprises the following steps of: preparing a solution at first, detecting the corresponding intensity of boron in the solution by utilizing an inductively coupled ion spectrometer, and finally, processing data to obtain the content of boron in the dalteparin sodium production process. The method for detecting the content of boron in the dalteparin sodium production process disclosed by the invention is capable of detecting the content of boron simply, rapidly and accurately; therefore, the problem of unqualified finished products due to the fact that the content of boron cannot be detected in the dalteparin sodium production process is overcome; the product qualification rate can be effectively increased; the unqualified risk of heparin sodium products and the production cost of enterprises are greatly reduced; simultaneously, the drug use risk of people is greatly reduced; furthermore, the method is simple to operate; and thus, industrial popularization and application are facilitated.

Owner:SHANDONG CHENZHONG BIOPHARM +1

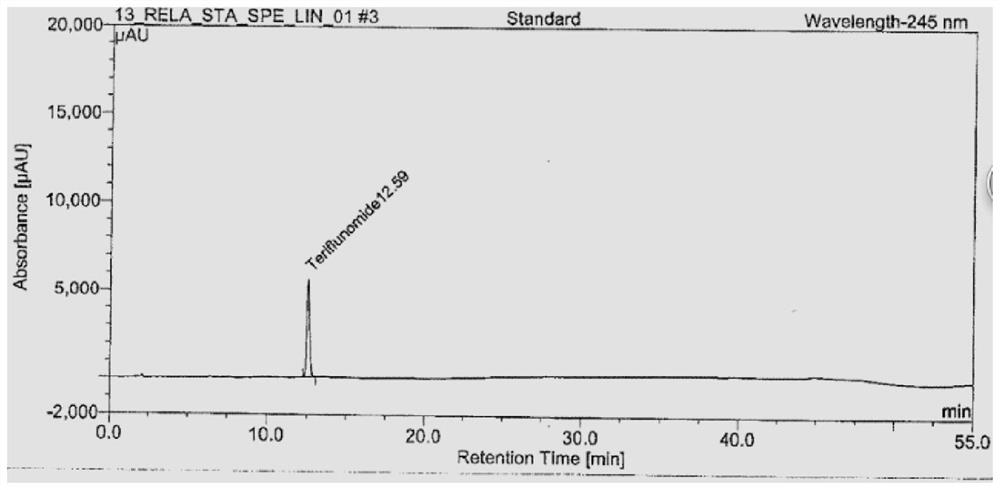

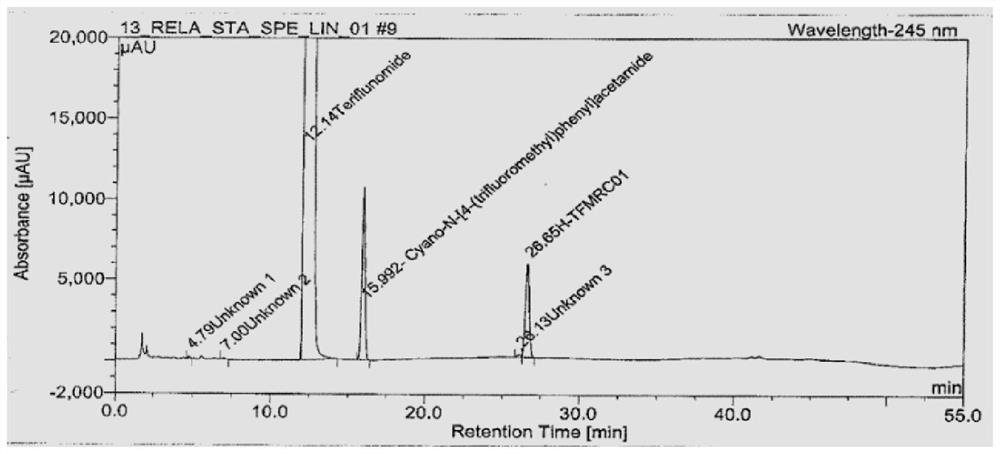

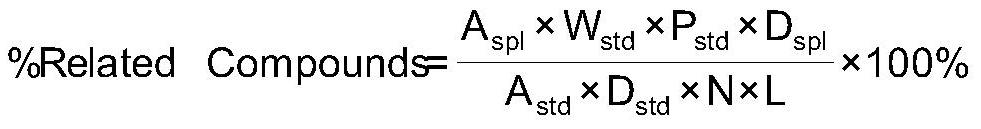

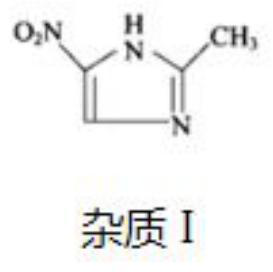

Method for detecting related substances of teriflunomide tablets

InactiveCN112305097AQuality improvementQuality assuranceComponent separationFluid phaseUltraviolet detectors

The invention discloses a method for detecting related substances of teriflunomide tablets. According to the method, a gradient reverse liquid chromatography analysis method is adopted, and an ultraviolet detector is used for detecting related substances in the teriflunomide tablet, so the purpose of controlling the quality of the teriflunomide finished product is achieved. The detection method provided by the invention can simply, rapidly and accurately detect the content of known impurities and unknown impurities in the teriflunomide tablet, so that the disqualification risk and the production cost of a finished product are reduced, the quality of the product is ensured, and the detection method has a very good application and popularization value.

Owner:CISEN PHARMA

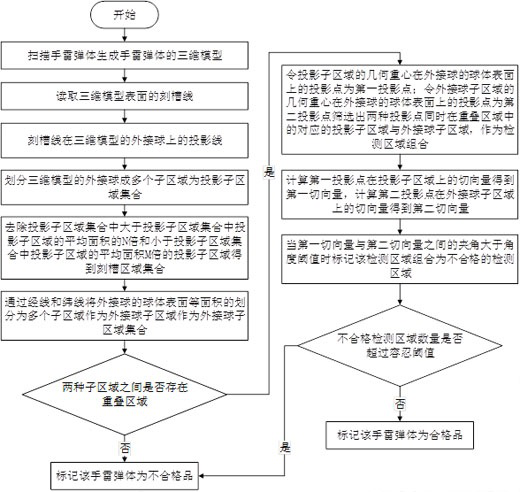

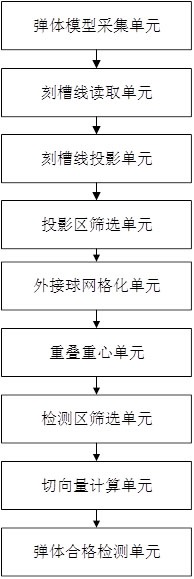

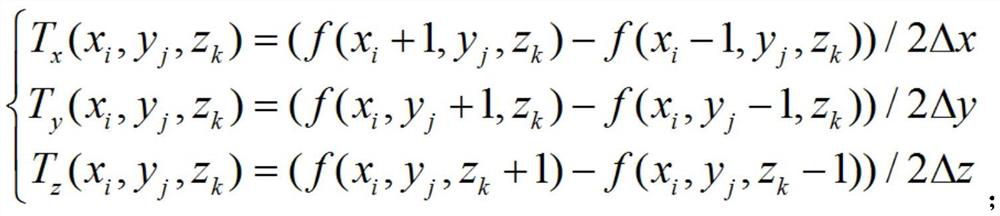

A quality inspection method and system for hand grenades based on visual recognition

ActiveCN111932528BReduce the risk of non-conformityReduce instabilityImage enhancementImage analysisEngineeringVisual recognition

The invention discloses a grenade quality detection method and system based on visual recognition. The three-dimensional model of the projectile body of the grenade is reconstructed in the computer through three-dimensional scanning, and the engraved groove formed by each groove line is quickly calculated according to the three-dimensional model of the projectile body. The center of gravity on the circumscribed circle of the groove surface is used to calculate the error angle between its tangent vector and the circumscribed circle tangent vector; when the number of unqualified detection areas in the projectile detection area of all grenades exceeds the tolerance threshold, the grenade is marked The projectile is a substandard product, otherwise it is a qualified product, so that the products with a large error angle are screened out, and the products with a small error angle are screened out to help improve the stability of the projectile structure and reduce the unevenness of the projectile body and the uneven thickness of the projectile. The product leads to the risk of being unqualified and reduces the probability of projectile instability. The invention is applied to the detection of grenade projectile products.

Owner:GUANGDONG MINGHUA MACHINERY

Solvent system capable of effectively dissolving ornidazole or left-ornidazole and application thereof

ActiveCN110934824BReduce dosageImprove performanceAntibacterial agentsOrganic active ingredientsIrritationPolythylene glycol

The invention discloses a solvent system capable of effectively dissolving ornidazole or left-ornidazole and its application. The active ingredient is ornidazole or left-ornidazole, and the solvent system is an organic solvent mixed with short-chain polyethylene glycol and propylene glycol; The short-chain polyethylene glycol is preferably polyethylene glycol 300 or / and polyethylene glycol 400. The solvent system can be used in the preparation of ornidazole injection or left-ornidazole injection. The present invention has technical advantages that cannot be achieved by the prior art. The preparation of ornidazole injection or left-ornidazole injection has the advantages of simpler prescription, safer production, more stable preparation, less solvent content, and impurities (especially genes) Toxic impurities) content is lower, low temperature is not easy to crystallize, low incidence of phlebitis, no irritation of low pH infusion, more suitable for patients with sensitive disulfiram reactions, etc., to ensure safer clinical medication and drug compliance of patients better.

Owner:CHONGQING DIANSUO MEDICAL TECH CO LTD

A kind of quality control method of aluminum magnesium suspension

ActiveCN105911057BReduce the risk of non-conformityGuarantee safe and effectiveMaterial analysis by observing effect on chemical indicatorFlow propertiesQuality controlViscosity coefficient

The invention relates to a quality control method of an almagate suspension, and the method is easy and convenient to operate. The method comprises the steps of (1), quality control of a suspension phase: the sedimentation volume ratio F is measured, and the F should be larger than or equal to 95.0%; (2) quality control before filling: absorption of acid is measured, the consumption of each 1g of almagate suspension on a hydrochloric acid volumetric solution (0.1 mol / L) should be larger than or equal to 23.0 mL; viscosity is measured, and the measured viscosity coefficient eta should be 1,200+-400 mPa.s. The preparation process of the almagate suspension is subjected to quality control with the method, preventive measures are taken in advance, the rick of unqualified finished products is reduced greatly, and clinical medicine is ensured to be safe and effective.

Owner:YANGZHOU YIYANG PHARMA

Device and method for fast alignment of datum in NC machining of non-regular shape structure wool

ActiveCN103481085BEasy to operateReduce the risk of non-conformityAutomatic control devicesFeeding apparatusNumerical controlDatum reference

Owner:SHENYANG AIRCRAFT CORP

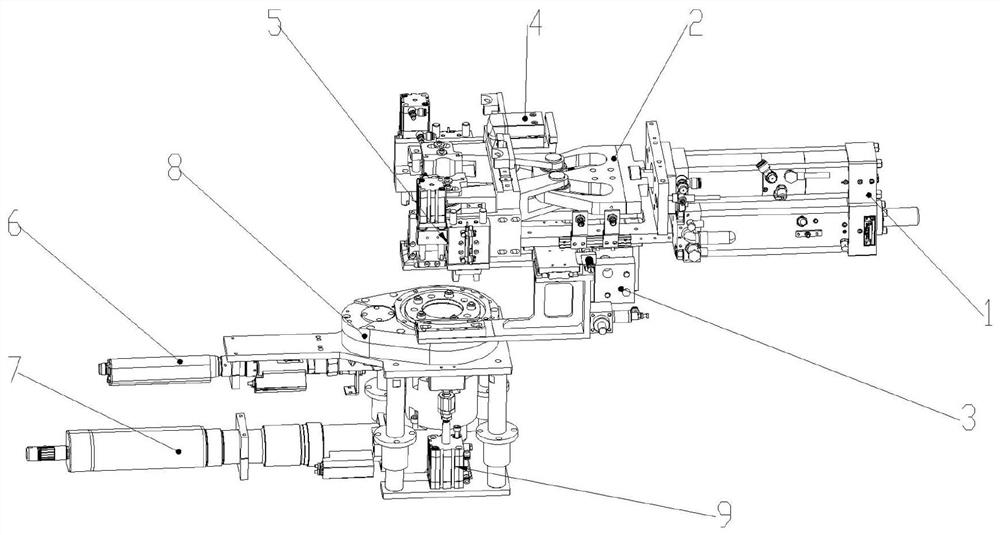

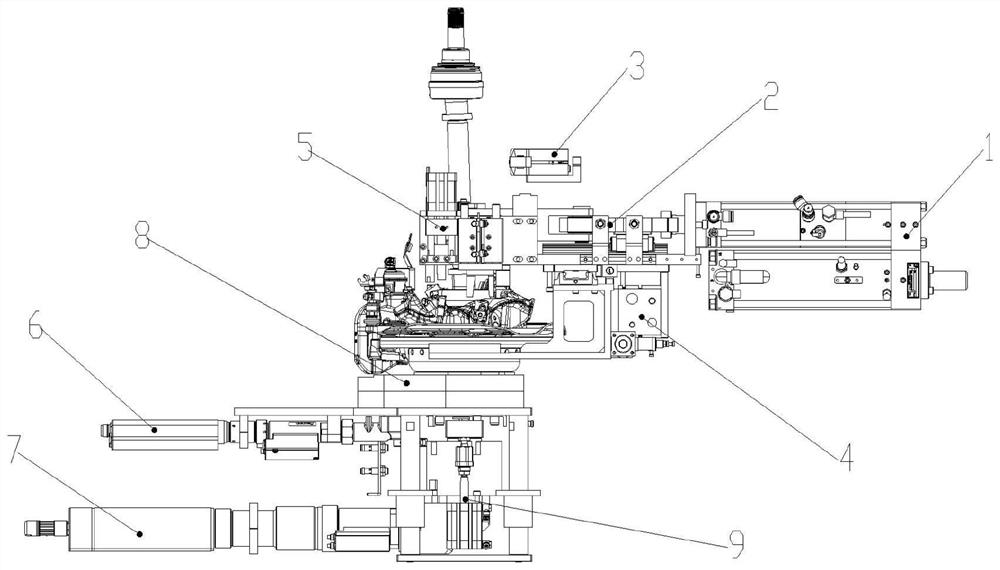

A half-shaft tooth-to-tooth detection and tightening central screw device

ActiveCN111347239BReduce the risk of non-conformityFast tempoMetal working apparatusBrakeEconomic benefits

The invention provides a half-shaft tooth-to-teeth detection and tightening center screw equipment, which includes a clamping mechanism and a testing mechanism, wherein the clamping mechanism includes a clamping and anti-torsion mechanism, a brake disc clamping claw cylinder mechanism, and a half-shaft centering clamp Jaw cylinder and compression cylinder mechanism; testing mechanism includes testing servo tightening shaft, central screw servo tightening shaft, hollow gear box and pneumatic spring. The embodiment of the invention can reduce the risk of unqualified parts caused by the teeth not meshing in the production line, not only improves the production line beat, but also improves the economic benefits of the automobile enterprise; in addition, the semi-axis tooth-to-tooth detection and tightening center screw equipment is installed on the pallet production line , to achieve fully automatic testing and central screw tightening, which is more efficient, faster and safer than traditional assembly line operations.

Owner:SHANGHAI SK SPECIAL MACHINERY CO LTD

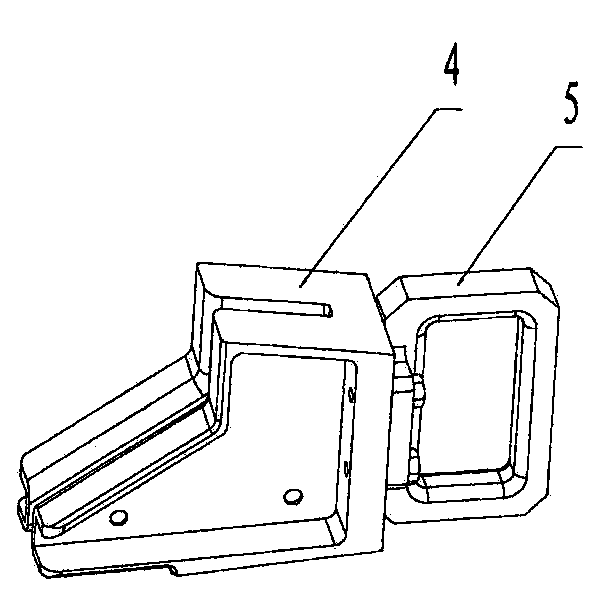

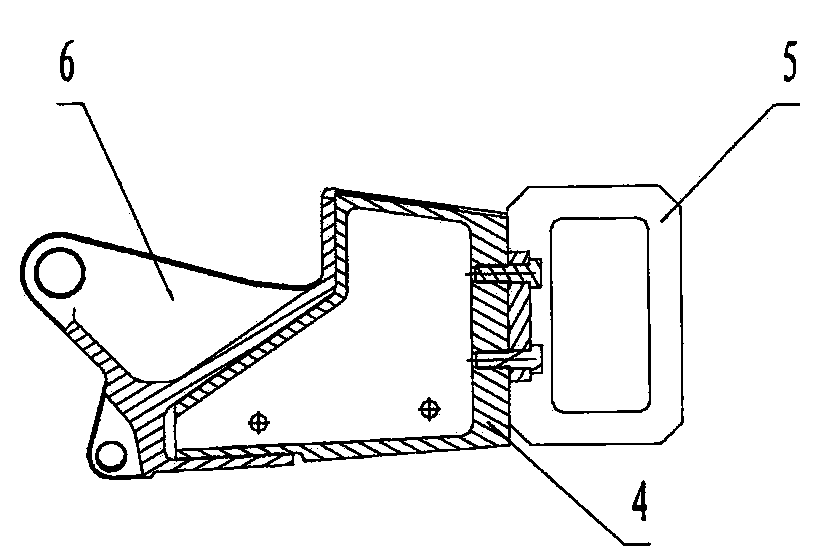

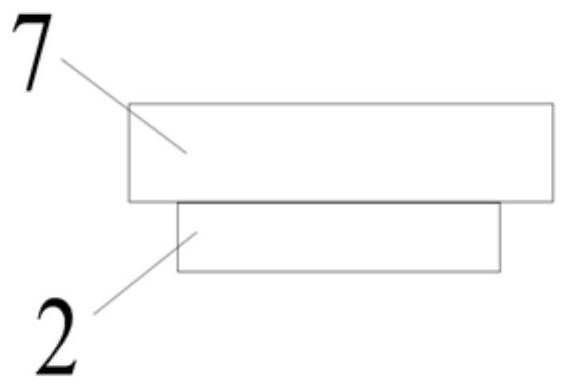

A lateral thruster and positioning method for machining aircraft thin-walled parts

ActiveCN103481086BHigh clamping reliabilityOvercoming extrusion clamping deformationWork holdersPositioning apparatusNumerical controlEngineering

A side thruster for aircraft thin-wall part processing comprises a guide block, a pressing plate and a clamp plate. The guide block is located above the clamp plate, the pressing plate is arranged above the guide block, the end of the pressing plate is of a zigzag shape, a first bolt passes through a waist-shaped groove of the pressing plate to be connected with the guide block in threaded manner, a third bolt passes through the waist-shaped grooves of the pressing plate and the guide block to be connected with the clamp plate in a threaded manner, a second bolt passes through a wedge block and the pressing plate to be connected with the guide block in a threaded manner, a spring washer is arranged between the first bolt and the waste-shaped groove of the pressing plate, and an angle gasket is arranged between the third bolt and the waste-shaped groove of the pressing plate. The positioning method includes: mounting an aircraft thin-wall part on the clamp plate, moving the side thruster to allow the zigzag-shaped surface of the end of the pressing plate to be in appearance contact with the aircraft thin-wall part, and respectively fixing the side thrusters on the appearance surface of the thin-wall part. By the side thruster, clamping reliability during numerical-control processing of the aircraft thin-wall part is improved, clamping deformation due to extrusion of the aircraft thin-wall part is avoided, risk of unqualified products is reduced, and practicability is good.

Owner:SHENYANG AIRCRAFT CORP

Solvent system capable of effectively dissolving ornidazole or left-ornidazole and injection thereof

ActiveCN110917135BReduce dosageImprove performanceAntibacterial agentsOrganic active ingredientsPolythylene glycolOrganosolv

The invention discloses a solvent system capable of effectively dissolving ornidazole or left-ornidazole and an injection thereof, the active ingredient is ornidazole or left-ornidazole, and the solvent system is a mixture of short-chain polyethylene glycol and ethanol The organic solvent of short-chain polyethylene glycol is preferably polyethylene glycol 300 or / and polyethylene glycol 400. The mixed mass fraction ratio of short-chain polyethylene glycol and ethanol in the solvent system is 30-100:0-70. The present invention has technical advantages that cannot be achieved by the prior art. The ornidazole injection or left-ornidazole injection has the advantages of simpler prescription, safer production, more stable preparation, less solvent content, and impurities (especially genotoxic impurities). ) content is lower, the number of impurities is less, low temperature is not easy to crystallize, the incidence of phlebitis is low, no low pH infusion irritation, no propylene glycol and other unique preparation advantages ensure safer clinical medication and better drug compliance of patients.

Owner:SOUTHWEST UNIV +1

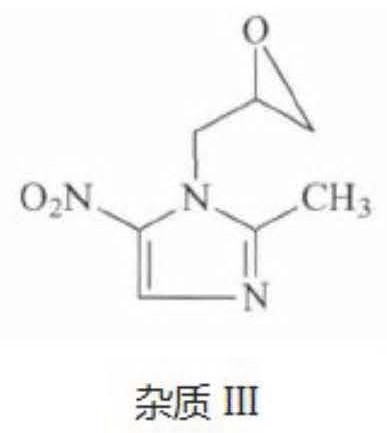

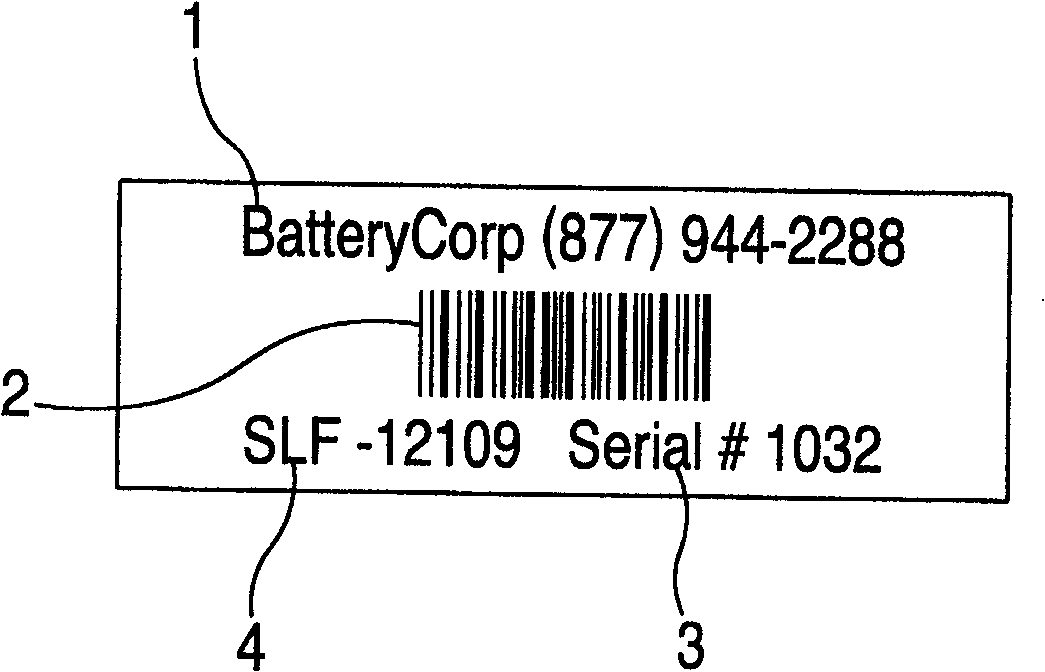

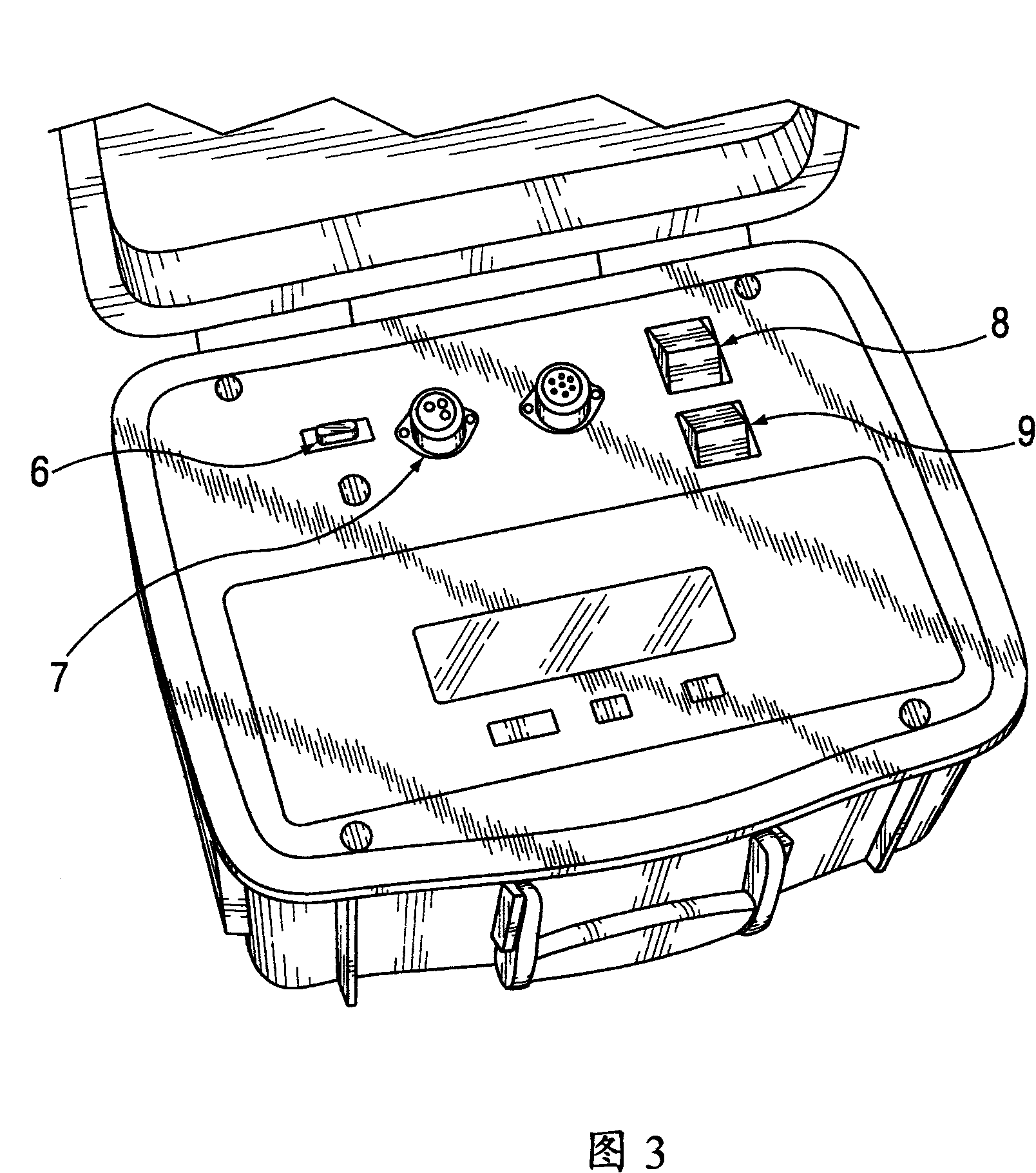

Battery management system and apparatus with runtime analysis reporting function

ActiveCN1862281BWidely dispersedImprove reliabilityData processing applicationsElectrical testingData acquisitionBarcode

The invention relates to the management of large stationary batteries. The invention is a comprehensive process for the management of stationary batteries that are used for backup power and are deployed in widely dispersed locations. The OMS(TM) (Optimization Management System) solution is comprised of Mega-Tags (preferably serialized bar-coded identification labels), a battery testing and data acquisition device, and web-based software. The OMS(TM) system can automatically analyze, determine and report an estimated runtime for battery unit, such as the length of time that a backup system canprovide adequate power to keep the primary equipment operational. These components work together to provide a platform for managing a large number of perishable, expensive, and geographically dispersed assets.

Owner:BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com