A rubber hose vulcanization mold core and its mold

A vulcanization mold and vulcanization mold technology, applied in the field of molds, can solve the problems of easily scalded products, increased product processing time, labor costs, and low pass rate, so as to reduce material waste and labor costs, and reduce unqualified products. risk, and the effect of improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

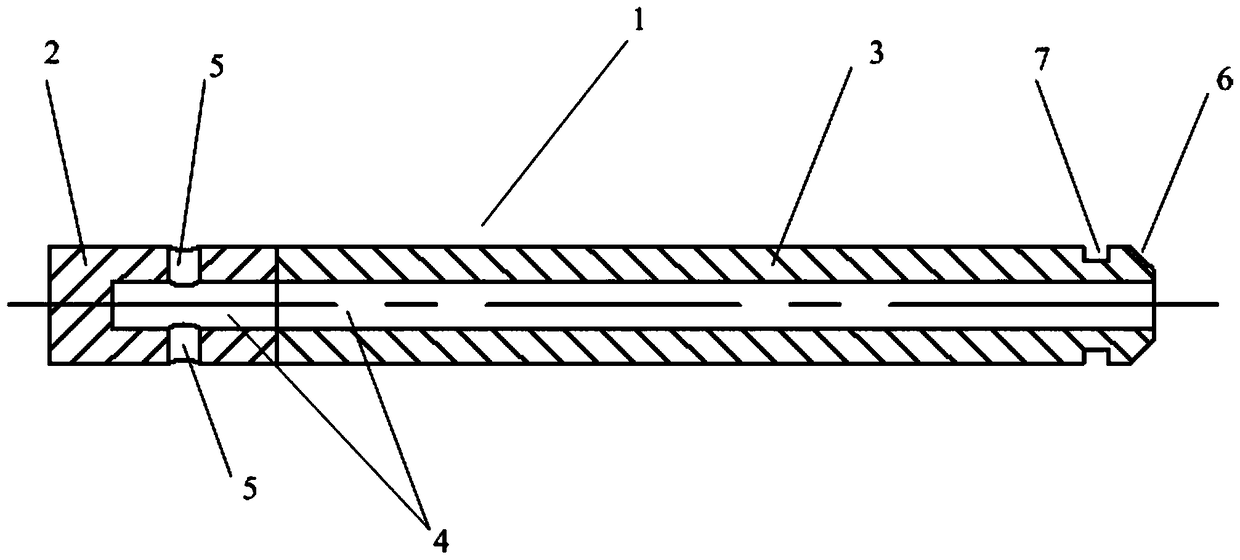

[0030] figure 1 It is a sectional view of the rubber hose vulcanization mold core provided by Embodiment 1 of the present invention.

[0031] Such as figure 1 As shown, a rubber hose vulcanization mold core, the mold core 1 includes a fixing part 2 and a forming part 3, the fixing part 2 and the forming part 3 are fixed by welding, and the inside of the mold core 1 is provided with a passage along the axis Air hole 4, the part of the vent hole 4 located at the fixing part 2 is a blind hole, the part of the vent hole 4 located at the forming part 3 is a through hole, and the fixed part 2 of the mold core 1 is also provided with at least one air inlet hole 5. The air inlet 5 communicates with the outer surface of the fixed part 2 and the air hole 4. The mold core 1 provided with the air inlet 5 and the air hole 4 proposed by the present invention effectively improves the heat dissipation speed. And it forms a certain pressure on the inner wall of the rubber tube blank, which i...

Embodiment 2

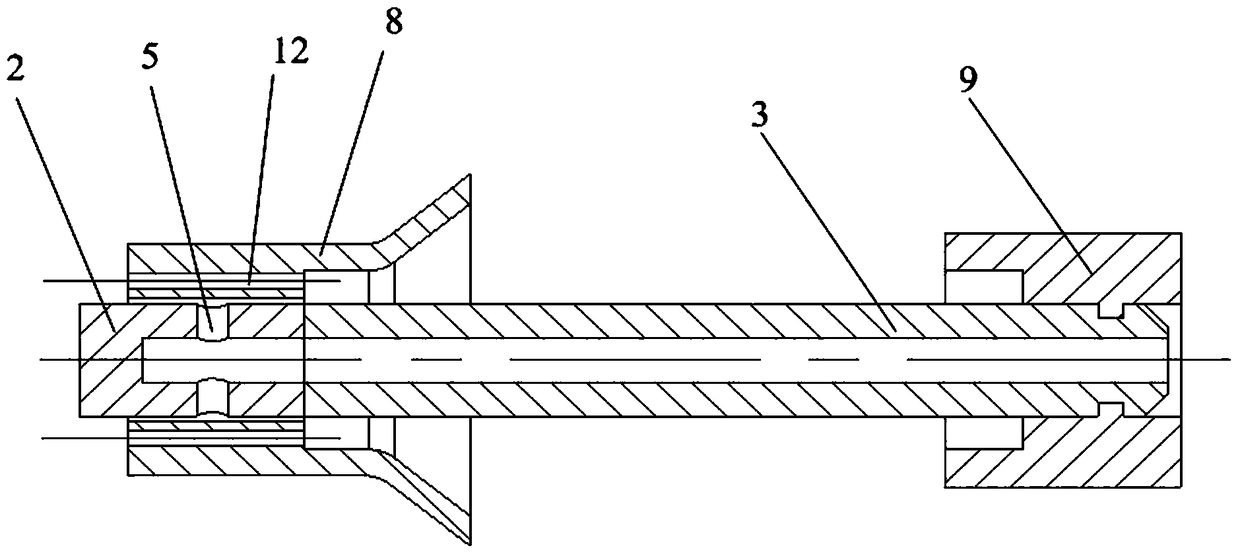

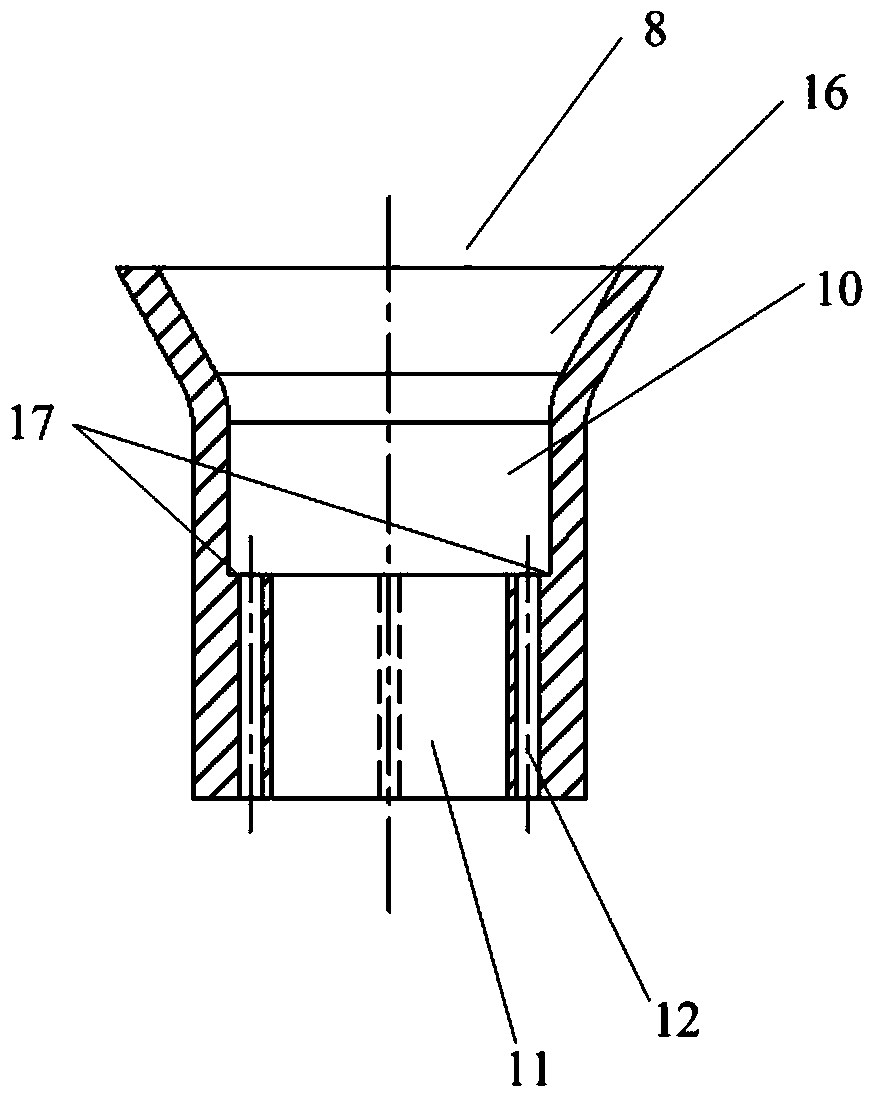

[0036] figure 2 It is a sectional view of the rubber hose vulcanization mold provided by Embodiment 2 of the present invention; image 3 It is a cross-sectional view of the first die sleeve provided by Embodiment 2 of the present invention; Figure 4 It is a cross-sectional view of the second die sleeve provided by Embodiment 2 of the present invention.

[0037] Such as figure 2 and image 3 As shown, a rubber hose vulcanization mold is characterized in that it includes the rubber hose vulcanization mold core as described in Embodiment 1, the mold also includes a rubber hose vulcanization mold cover, and the rubber hose vulcanization mold cover includes a first mold cover 8 and The second mold case 9 , the first mold case 8 is placed on one end of the mold core 1 close to the fixing part 2 , and the second mold case 9 is placed on the other end of the mold core 1 .

[0038] The inside of the first mold cover 8 is provided with a first hole 10 and a second hole 11 positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com