Special machining tool base for special type steel cylinder opening and machining method

A special type, tool holder technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem that the processing process of the special type cylinder mouth cannot be completed by a lathe or a clamping, so as to reduce the unqualified risk, reduce vibration, and avoid the effect of unbalanced forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

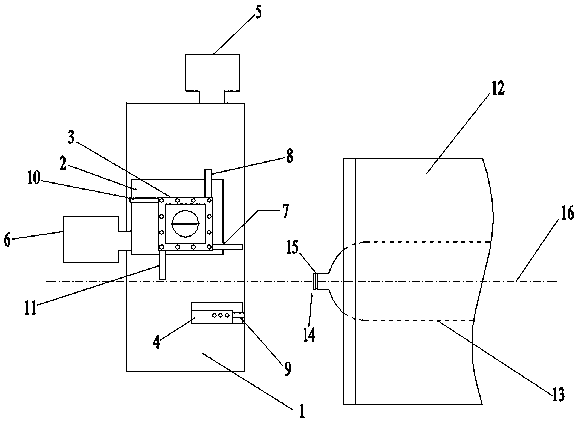

[0027] This embodiment provides a special processing tool holder for processing the mouth of small and medium-sized steel cylinders with horizontal handles, including a middle slide 1 , a small slide 2 , a square tool holder 3 , a first servo motor 5 and a second servo motor 6 . Wherein, the middle slide plate 1 is installed on the transverse guide rail of the lathe bed, and can drive the turning tool to move laterally along the guide rail. Small slide plate 2 is installed on the guide rail on the middle slide plate 1, can move short distance along the guide rail on the middle slide plate 1. Square knife rest 3 is installed on the small slide plate 2, can rotate any angle in the horizontal plane, is used for clamping cutter.

[0028] The square tool holder 3 is a square, with a tool position at each of the four corners. In the top view, the counterclockwise order is the first tool position 7, the second tool position 8, the fourth tool position 10 and the fifth tool position ...

Embodiment 2

[0033] This embodiment provides a method for processing the mouth of a horizontal handle-type small and medium-volume steel cylinder using the special processing tool holder described in Embodiment 1, which includes the following steps:

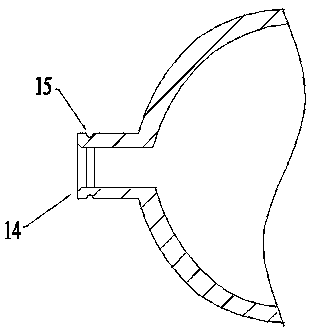

[0034] 1) Clamp the workpiece, clamp the steel cylinder 13 in the workpiece fixture 12, the bottle body lies horizontally, and the bottle mouth 14 faces the tool holder;

[0035] 2) Processing of the outer circle and end face, use the end face outer circle turning tool on the No. 1 tool position 7 to turn the end face and outer circle of the bottle mouth 14, and process the outer circle chamfering to size;

[0036] 3) Grooving, the control system of the CNC machine tool manipulates the square tool holder 3 to rotate horizontally, moves the grooving turning tool on the second tool position 8 to the processing station, and cuts the outer surface of the neck of the bottle mouth 14 according to the required size. A card slot 15 around the bottlen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com