Processing technology of quick-frozen Chinese cabbages

A processing technology and technology for cabbage, which is applied in the fields of freezing/refrigerating preservation of fruits/vegetables, preservation of fruits and vegetables, food ingredients as antifreeze, etc. Brightness, improved flavor, and easy cooking and processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

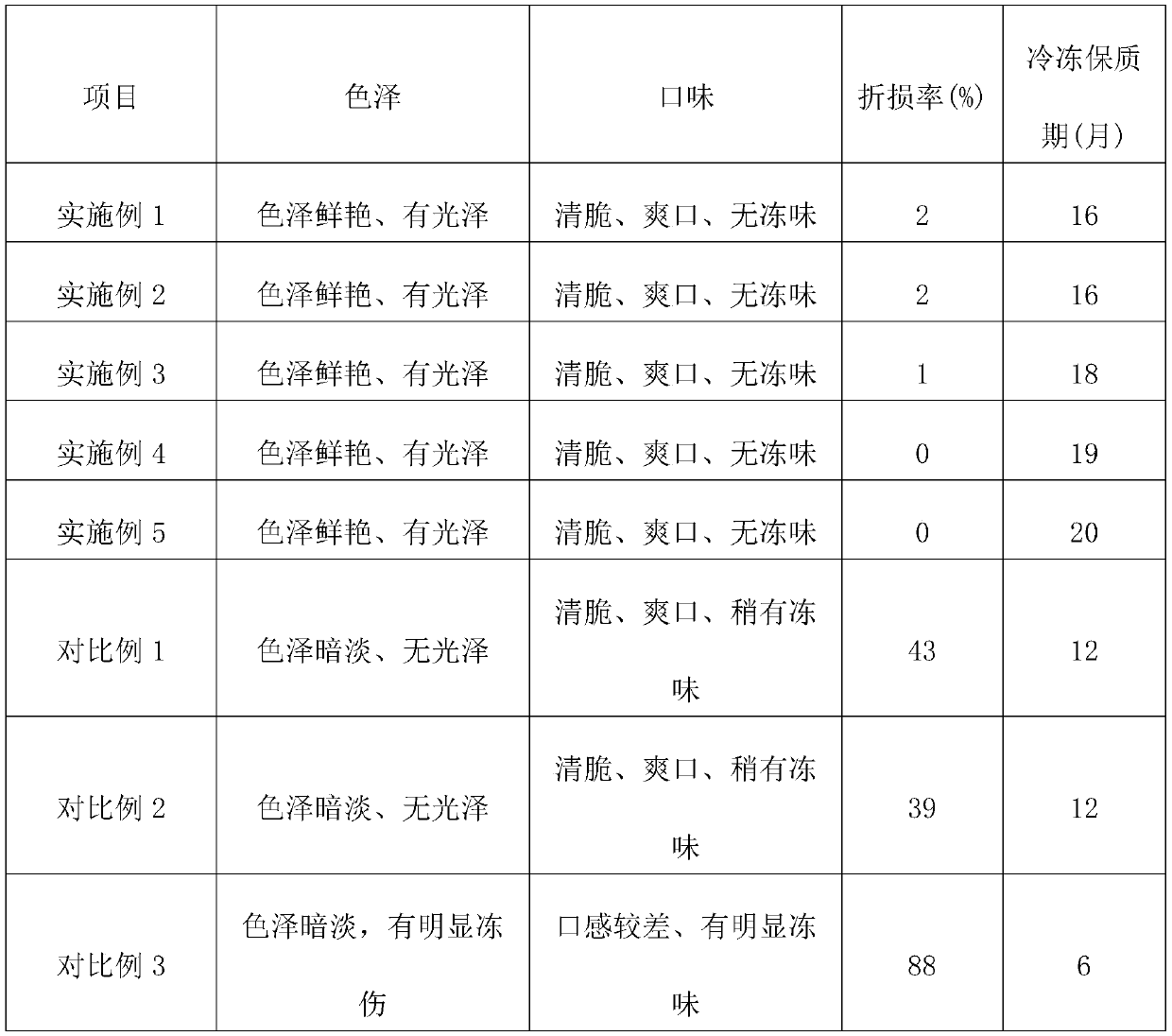

Examples

Embodiment 1

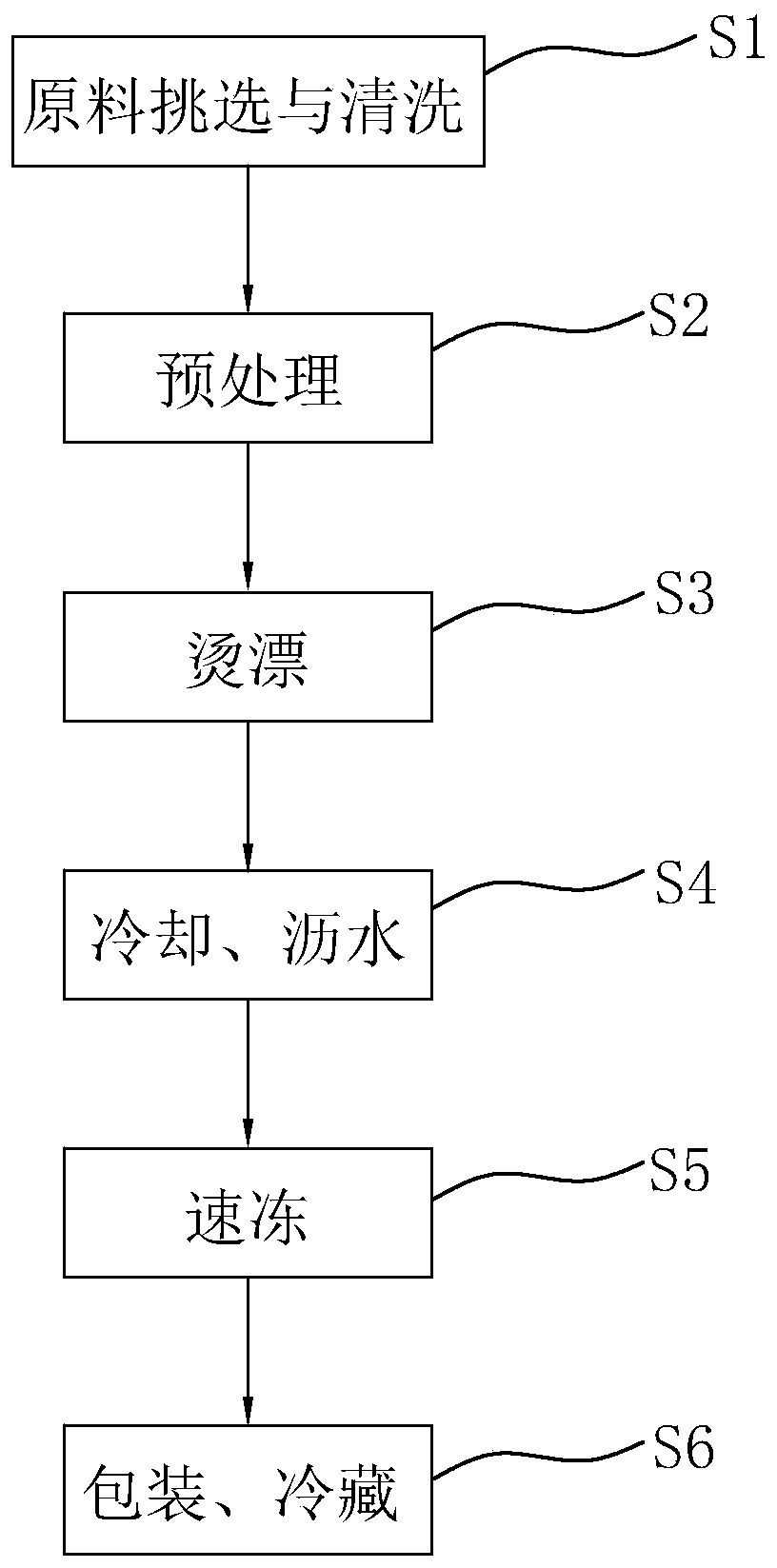

[0044] Embodiment 1: a kind of processing technology of quick-frozen Chinese cabbage, concrete operation is as follows:

[0045] S1, selection and cleaning of raw materials: use a color sorter to select brightly colored cabbage and rinse it with clean water;

[0046] S2, pretreatment: put the rinsed cabbage into a pool for soaking, and add 2 wt.% of the cabbage weight antifreeze into the pool for 10 minutes;

[0047] S3, blanching: put the pretreated cabbage into a blanching machine for blanching for 2 minutes, and control the water temperature to 98°C;

[0048] S4, cooling and draining: the blanched cabbage is cooled to room temperature by air cooling, and the cooled cabbage is drained;

[0049] S5, quick freezing: quickly cool the drained cabbage to -8°C and keep it for 1min, then quickly raise the temperature to -4°C and keep it for 1min, then quickly cool it down to -20°C and keep it for 15min;

[0050] S6, packaging and refrigerating, weighing and packaging the quick-fr...

Embodiment 2

[0059] Embodiment 2: a kind of processing technology of quick-frozen Chinese cabbage, concrete operations are as follows:

[0060] S1, selection and cleaning of raw materials: use a color sorter to select brightly colored cabbage and rinse it with clean water;

[0061] S2, pretreatment: put the rinsed cabbage into a pool for soaking, and add 0.5 wt.% of the cabbage weight antifreeze into the pool for 30 minutes;

[0062] S3, blanching: put the pretreated cabbage into a blanching machine for 3 minutes, and control the water temperature to 98°C;

[0063] S4, cooling and draining: the blanched cabbage is cooled to room temperature by air cooling, and the cooled cabbage is drained;

[0064] S5, quick freezing: quickly cool the drained cabbage to -10°C and keep it for 0.5 minutes, then quickly raise the temperature to -4°C and keep it for 0.5 minutes, then quickly cool it down to -27°C and keep it for 15 minutes;

[0065] S6, packaging and refrigerating, weighing and packaging th...

Embodiment 3

[0074] Embodiment 3: A processing technology of quick-frozen cabbage, the difference from Example 1 is that in the step S2 pretreatment, the amount of antifreeze added is 1.3wt.% of the cabbage weight; and the antifreeze includes the following parts The components of:

[0075] Modified starch: 6 parts;

[0076] Sodium lactate: 0.05 parts;

[0077] Sodium sorbate: 0.05 parts;

[0078] Hydroxymethylcellulose: 0.15 parts;

[0079] Chitosan: 0.25 parts;

[0080] Tea polyphenols: 0.35 parts;

[0081] Orange peel extract: 0.35 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com