Production process of fine-point round-toe crab meat recombined product

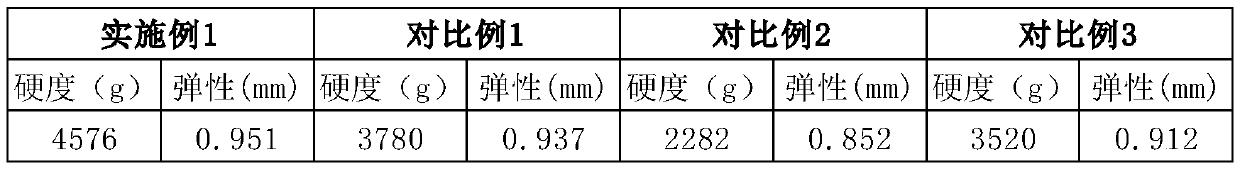

A production process and technology of crab meat, applied in the direction of food ingredients as antimicrobial preservation, food ingredients, food ingredients functions, etc., can solve the problem of underutilization, easy blackening, and economic losses of small-pointed round-toed crabs, etc. problems, to achieve the effect of good flavor and taste, high elasticity, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Meat harvesting: After washing the fresh round-toed crabs, open the shells and harvest the meat, and store the harvested crab meat at a temperature below 0°C for temporary storage until use;

[0026](2) Color protection: Soak crab meat in color protection solution for 15 minutes, remove and drain. The color protection solution is an aqueous solution containing 0.01% EDTA and 0.3% citric acid, crab meat and color protection solution The mass ratio is 1:8), and the temperature of the color protection solution is controlled at 10°C;

[0027] (3) Empty beating: put crab meat, sea fish meat with 15% crab meat mass and pig fat with 8% crab meat mass in a vacuum chopping machine for chopping and mixing for 3 minutes to get thick crab meat. The temperature of the air beating is controlled at 10°C;

[0028] (4) Salt beating and ultrasonic treatment: Based on the mass of the thick crab meat, add 3% salt and 10% ice water, chop and mix in a vacuum for 5 minutes, put the thick...

Embodiment 2

[0047] (1) Meat harvesting: After washing the fresh round-toed crabs, open the shells and harvest the meat, and store the harvested crab meat at a temperature below 0°C for temporary storage until use;

[0048] (2) Color protection: Soak crab meat in color protection solution for 12 minutes, remove and drain. The color protection solution is an aqueous solution containing 0.007% EDTA and 0.28% citric acid, crab meat and color protection solution The mass ratio is 1:6, and the temperature of the color protection solution is controlled at 6°C;

[0049] (3) Empty beating: put crab meat, sea fish meat with 12% crab meat mass and pig fat with 6% crab meat mass in a vacuum chopping machine for chopping and mixing for 2 minutes to obtain thick crab meat. The temperature of the air beating is controlled at 8°C;

[0050] (4) Salt beating and ultrasonic treatment: Based on the mass of the coarse crab meat, add 2.5% salt and 9% ice water, chop and mix in a vacuum for 4 minutes, put the ...

Embodiment 3

[0056] (1) Meat harvesting: After washing the fresh round-toed crabs, open the shells and harvest the meat, and store the harvested crab meat at a temperature below 0°C for temporary storage until use;

[0057] (2) Color protection: Soak the crab meat in the color protection solution for 10 minutes, remove and drain, the color protection solution is an aqueous solution containing 0.005% EDTA and 0.25% citric acid, crab meat and color protection solution The mass ratio is 1:5, and the temperature of the color protection solution is controlled at 5°C;

[0058] (3) Empty beating: put crab meat, sea fish meat with 10% crab meat mass and pig fat with 5% crab meat mass in a vacuum chopping machine for chopping and mixing for 1 min to obtain thick crab meat. The temperature of the air beating is controlled at 0°C;

[0059] (4) Salt beating and ultrasonic treatment: Based on the mass of the thick crab meat, add 2% salt and 8% ice water, chop and mix in a vacuum for 3 minutes, put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com