Fermentation method for low-salt thick broad-bean sauce

A fermentation method and bean paste technology are applied in the field of low-salt bean paste fermentation, which can solve the problems of rich flavor and taste, good fermentation effect, and miscellaneous taste of fermented grains, and achieve unique flavor, softer taste, and mellow aroma. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

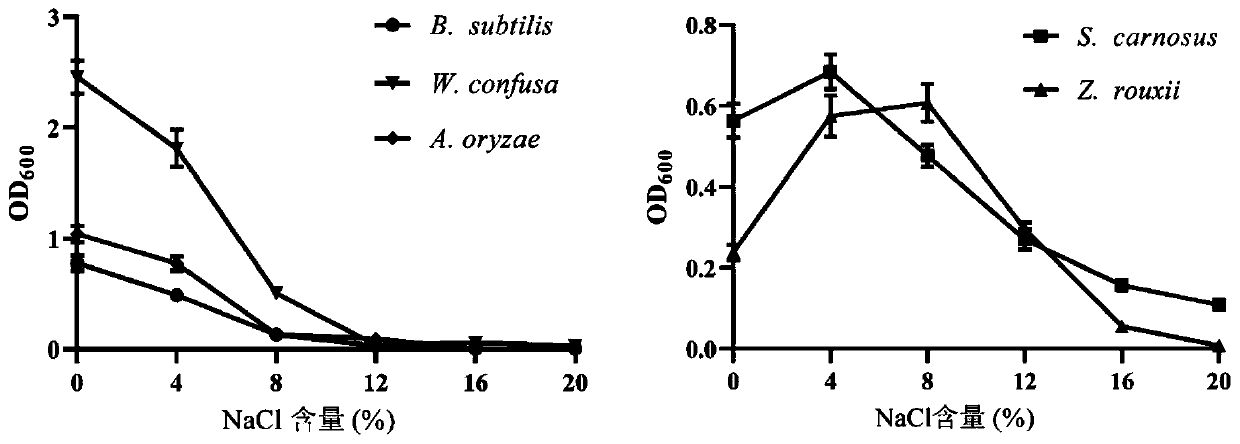

[0036] The microbial community structure in the fermentation process of traditional bean paste was analyzed by amplicon sequencing, and it was found that the main bacterial genera in the fermented bean paste were Staphylococcus, Bacillus and Weissella The genus Weissella accounted for 79.8%, 7.5% and 5.9% of the total bacteria, respectively; the fungal genera were mainly Aspergillus and Zygosaccharomyces, which accounted for 97% and 1.3% of the total fungi, respectively. Then, the microorganisms in the fermented sauce were isolated and purified, and based on the food safety of the strains, the representative species of these five dominant microbial genera were determined, namely Staphylococcus carnosus, Bacillus subtilis, Fusion Weissella confusa, Aspergillus oryzae and Zygosaccharmyces rouxii.

Embodiment 2

[0037] The cultivation of embodiment 2 bacterial strains

[0038] PDA medium: Add 200 g of potatoes to boil and filter, add 20 g of glucose and 20 g of agar, and dilute to 1 L with deionized water.

[0039] YPD medium: glucose 20g, peptone 20g, yeast powder 10g, dilute to 1L with deionized water.

[0040] MRS medium: glucose 20g, peptone 10g, beef extract 10g, yeast powder 5g, sodium acetate 5g, diammonium hydrogen citrate 2g, dipotassium hydrogen phosphate 2g, Tween-80 1.0mL, magnesium sulfate 0.58g, manganese sulfate 0.25 g, use deionized water to make up to 1L.

[0041] Aspergillus oryzae was inoculated on the PDA slant medium, cultured statically at 28°C for 2-3d, and eluted with 0.9% physiological saline to prepare the spore suspension.

[0042] Inoculate Luxie combined yeast in MYPD liquid medium at an inoculum size of 1%, and culture at 30°C and 200rpm shaking until the middle and late logarithmic growth, OD 600 0.8 to 1.0.

[0043] Staphylococcus carnosus and fusio...

Embodiment 3

[0045] Function verification experiment of embodiment 3 bacterial strains

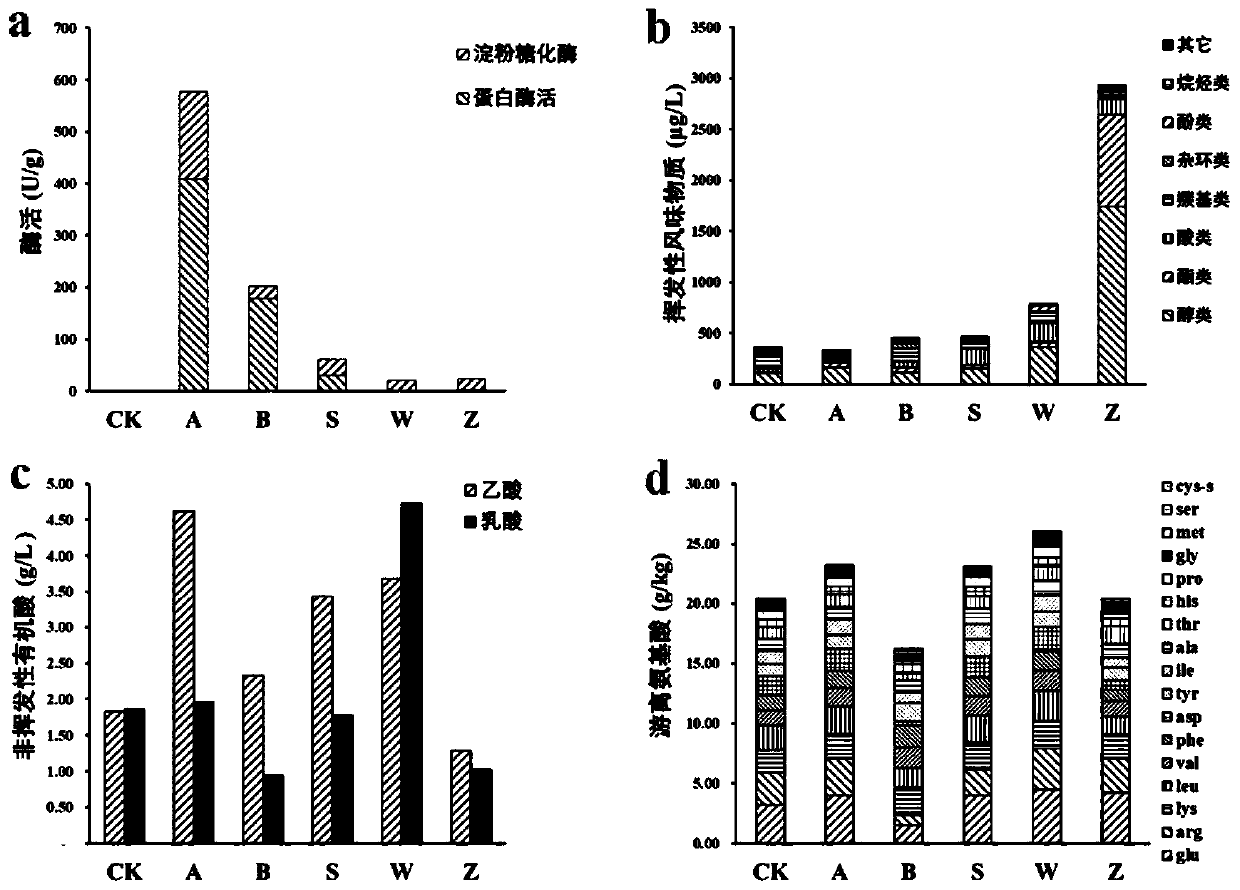

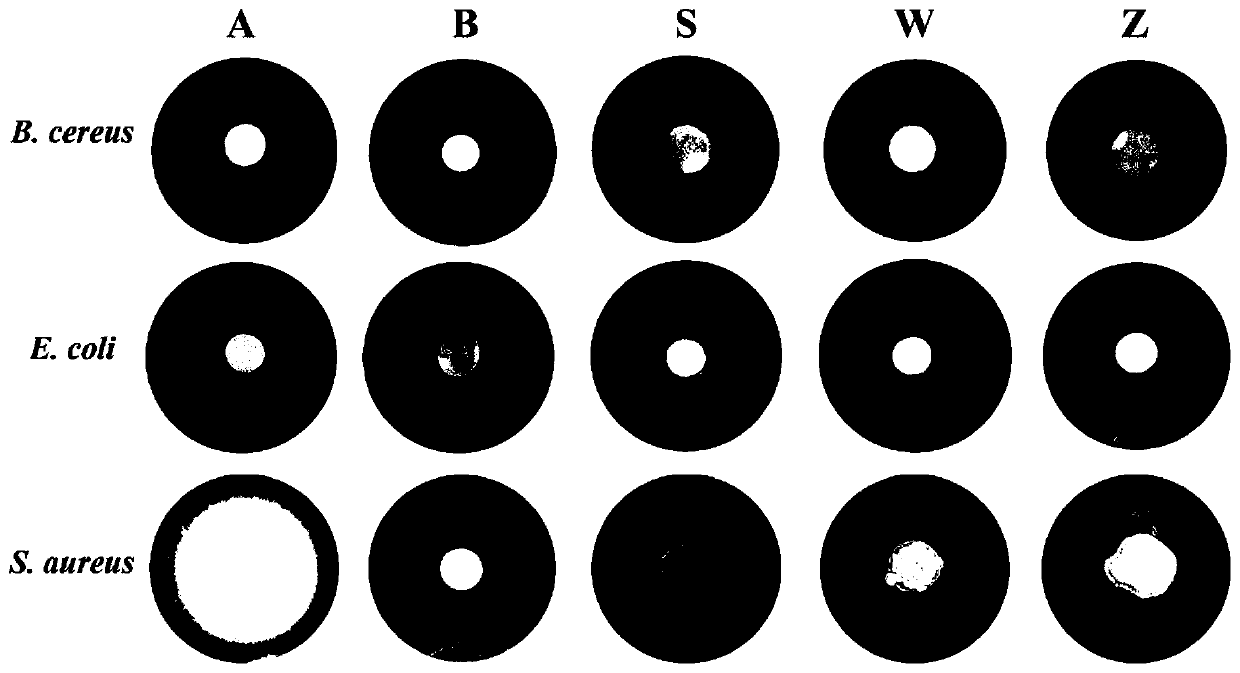

[0046] The functions of Aspergillus oryzae, Conjugative yeast ruckeri, Staphylococcus carnosus, Bacillus subtilis and fusion Lactobacillus weisnerii were verified by in vitro mixed culture fermentation method.

[0047] Add 10g of broad bean flour, 2.5g of wheat flour, and 50g of broad bean paste into 1.0L of deionized water and boil for 30min, then filter to prepare a simulated liquid medium. Then these strains were inoculated into the liquid medium to simulate the fermentation process of bean paste, and the initial cell density of each strain was adjusted to 1.0×10 6 CFU / g. All fermentations were carried out at 30°C for 3 days. After the fermentation, the flavor substances of the single-bacteria fermentation liquid were detected, and the uninoculated fermentation medium was used as the reference substance. All experiments were performed in triplicate.

[0048] Method for determination of organic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com