A production method of a health-care yeast glucan/surimi composite product that removes fishy smell and strengthens the gel

A technology of yeast glucan and composite products, applied in the directions of food ingredients, food heat treatment, and functions of food ingredients, etc., can solve problems such as restricting the development of the aquatic product processing industry, easy spoilage and deterioration of aquatic products, and low fresh sales prices of aquatic products, etc. To achieve the effect of enhancing elasticity, good elasticity and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

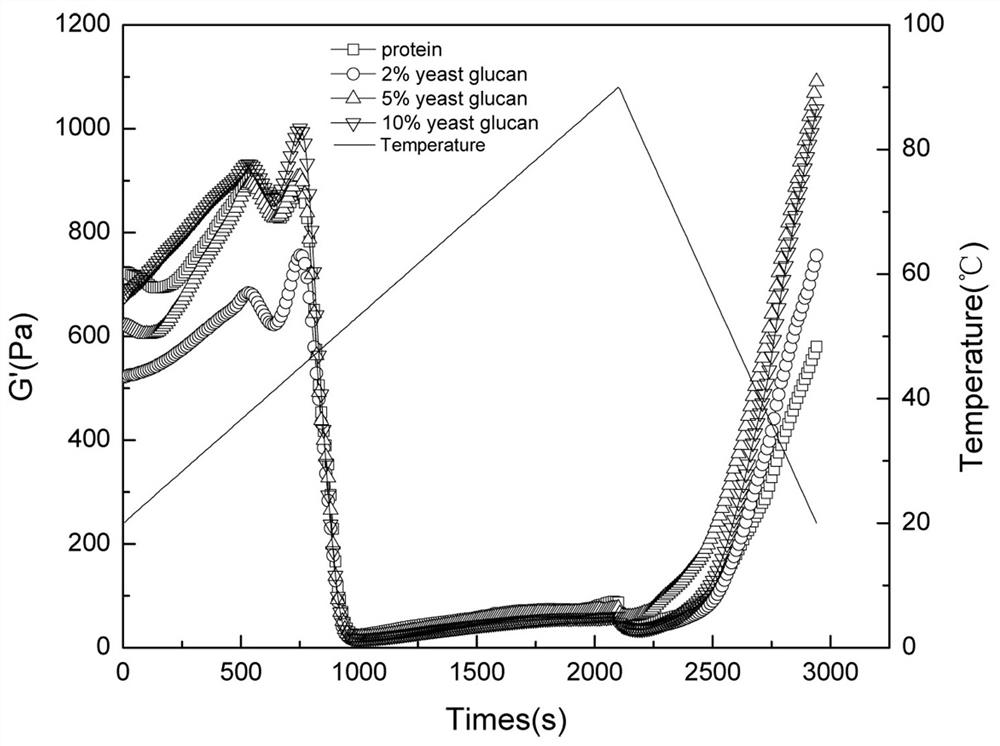

[0036] After fresh silver carp is cleaned, "three removals" (removing the head, removing scales and removing internal organs), the fish meat is collected by a meat harvester and rinsed at a water temperature of 0-10°C. The fish meat was rinsed three times, among which, the tap water was rinsed twice, and the 0.5% NaCl solution was rinsed once. Place the rinsed fish meat in a centrifuge to drain, chop it into a mince in a food processor, stir it to make it fully mixed, pour it into the casing, and seal the two ends with a bayonet machine. Adopt two-stage heating method, heat at 40°C for 1 hour, and heat at 90°C for 30 minutes. After the surimi gel is prepared, it is quickly cooled with running water, and refrigerated overnight at 0-4°C. The texture characteristics of the samples were determined by a texture analyzer, and the differences in volatile flavor components of the samples were detected by electronic nose and HS-SPME-GC-MS.

Embodiment 2

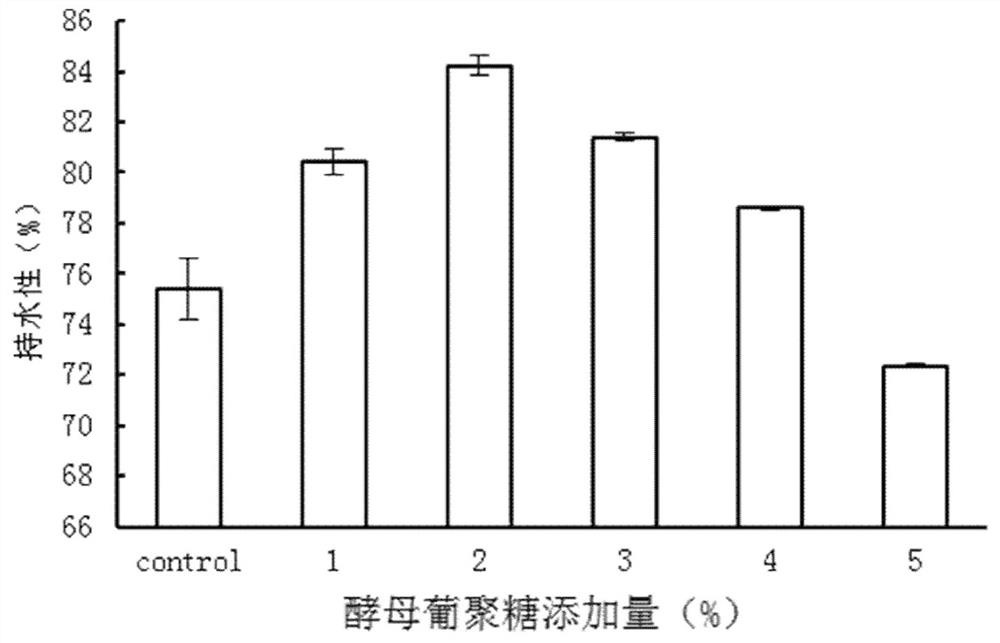

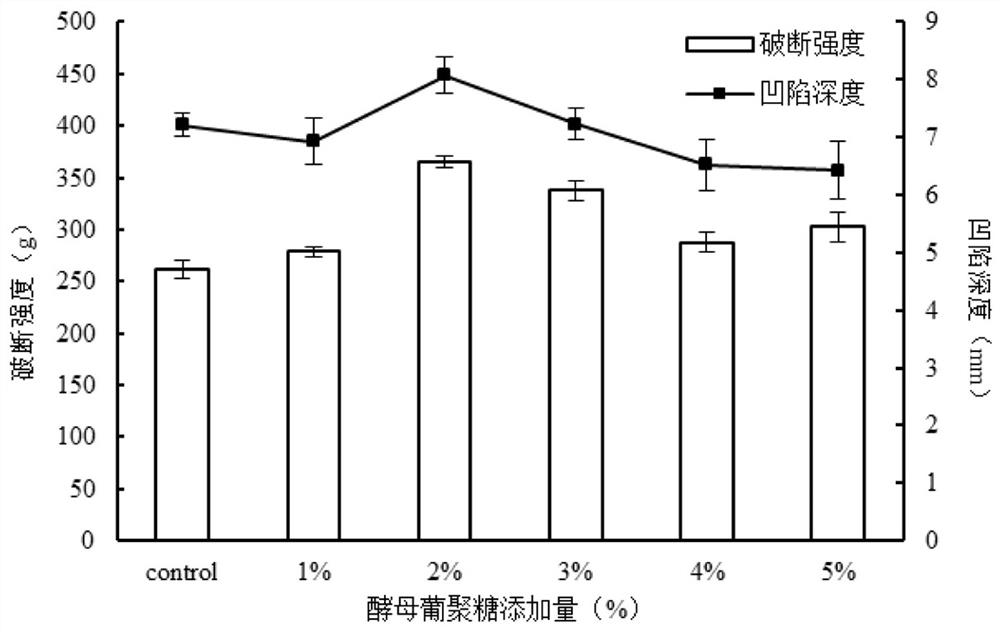

[0038]After fresh silver carp is cleaned, "three removals" (removing the head, removing scales and removing internal organs), the fish meat is collected by a meat harvester and rinsed at a water temperature of 0-10°C. The fish meat was rinsed three times, among which, the tap water was rinsed twice, and the 0.5% NaCl solution was rinsed once. Drain the rinsed fish in a centrifuge and chop into a mince in a food processor. The yeast dextran was pre-dispersed in ice water, stirred for more than 30 minutes, and the amount added was 1% of the total mass of the sample complex. Stir to make it fully mixed, pour it into the casing, and seal the two ends with a bayonet machine. Adopt two-stage heating method, heat at 40°C for 1 hour, and heat at 90°C for 30 minutes. After the surimi gel is prepared, it is quickly cooled with running water, and refrigerated overnight at 0-4°C. The texture characteristics of the samples were determined by a texture analyzer, and the differences in vol...

Embodiment 3

[0040] After the fresh silver carp is cleaned, "three removals" (removing the head, scales and viscera) are carried out, and the fish meat is harvested by a meat harvester and then rinsed. The fish meat was rinsed three times, among which, the tap water was rinsed twice, and the 0.5% NaCl solution was rinsed once. When rinsing, first stir slowly for 5 minutes, and then let it stand for 10 minutes. The ratio of fish meat to water is 1:5, and the water temperature is about 10°C. Drain the rinsed fish in a centrifuge and chop into a mince in a food processor. Add 3%-5% salt, 2%-5% sugar, 5%-6% starch, 10%-22% ginger water, 0.2%-0.6% pepper and 0.3%-0.5% monosodium glutamate, chop and mix well Then add 1%-5% yeast dextran of the total mass of the sample complex. Manually shaped to make fish balls. After heating and cooking, sensory evaluation was carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com