Highly wear-resistant anti-freezing glass ware and preparation process thereof

The invention relates to a glassware and a preparation process technology, which is applied in the field of high wear-resistant and antifreeze glassware and its preparation process, and can solve the problems of poor frost resistance and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

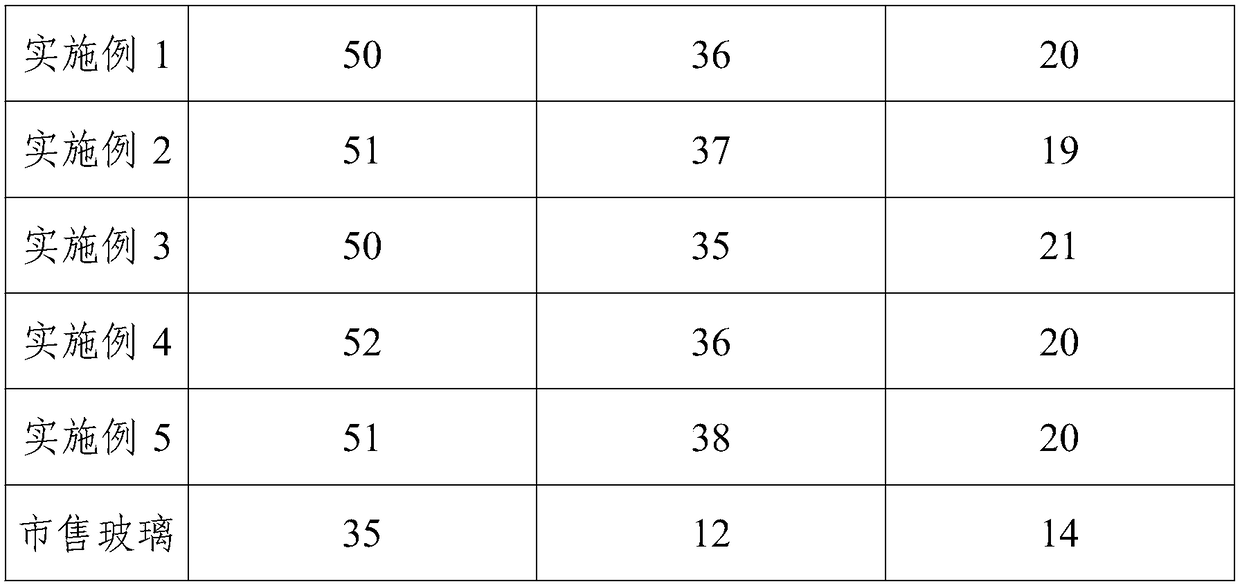

Examples

Embodiment 1

[0022] A high wear-resistant and antifreeze glassware, the glassware is made of the following raw materials in parts by weight: 60 parts of silicon dioxide powder, 20 parts of sodium carbonate, 3 parts of potassium carbonate, 6 parts of calcium oxide powder, 15 parts of fly ash , 8 parts of titanium dioxide powder, 3 parts of boron oxide powder, 9 parts of phosphoric acid, 1 part of aluminum powder.

[0023] The preparation technology of this glassware comprises the following steps:

[0024] (1) Take silicon dioxide powder, boron oxide powder and aluminum powder and stir evenly, as for heat treatment in a tube furnace at 1000°C for 2 hours in a nitrogen atmosphere, set aside;

[0025] (2) Add sodium carbonate, potassium carbonate, and calcium oxide powder into the reaction kettle, add water into it at a material-to-water ratio of 2:1, slowly heat up to 450°C under heating conditions, ultrasonically treat for 10 minutes, and cool to room temperature. Then vacuum dehydration, s...

Embodiment 2

[0029] A high wear-resistant and frost-resistant glass vessel, which is made of the following raw materials in parts by weight: 75 parts of silicon dioxide powder, 10 parts of sodium carbonate, 10 parts of potassium carbonate, 2 parts of calcium oxide powder, and 25 parts of fly ash , 4 parts of titanium dioxide powder, 7 parts of boron oxide powder, 4 parts of phosphoric acid, 6 parts of aluminum powder.

[0030] The preparation technology of this glassware comprises the following steps:

[0031] (1) Take silicon dioxide powder, boron oxide powder and aluminum powder and stir evenly, and heat treat in a tube furnace at 1100°C for 2 hours in a nitrogen atmosphere, and set aside;

[0032] (2) Add sodium carbonate, potassium carbonate, and calcium oxide powder into the reaction kettle, add water into it at a material-to-water ratio of 2:1, slowly heat up to 450°C under heating conditions, ultrasonically treat for 10 minutes, and cool to room temperature. Then vacuum dehydration...

Embodiment 3

[0036] A high wear-resistant and antifreeze glassware, the glassware is made of the following raw materials in parts by weight: 65 parts of silicon dioxide powder, 18 parts of sodium carbonate, 5 parts of potassium carbonate, 5 parts of calcium oxide powder, 16 parts of fly ash , 7 parts of titanium dioxide powder, 4 parts of boron oxide powder, 8 parts of phosphoric acid, 2 parts of aluminum powder.

[0037] The preparation technology of this glassware comprises the following steps:

[0038] (1) Take silicon dioxide powder, boron oxide powder and aluminum powder and stir evenly. As for nitrogen atmosphere, heat treatment in a tube furnace at 1100°C for 2 hours, and set aside;

[0039] (2) Add sodium carbonate, potassium carbonate, and calcium oxide powder into the reaction kettle, add water to it at a material-to-water ratio of 2:1, slowly heat up to 400°C under heating conditions, ultrasonically treat for 10 minutes, and cool to room temperature. Then vacuum dehydration, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com