Dye-adsorbing composite hydrogel microspores and preparation method thereof

A composite hydrogel and dye-adsorbing technology, which is applied in the preparation of microspheres for the preparation of dye-adsorbing composite hydrogels and the preparation field thereof, can solve the problems of single functional functional group on the surface of the gel, high toughness of polyvinyl alcohol gel, and waste liquid. It is necessary to collect problems such as unified collection to achieve the effects of broad industrial application prospects, low raw material prices, and firm interface bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

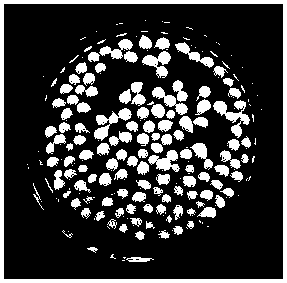

[0038]The microspheres of the dye-absorbing composite hydrogel are made of sodium alginate, magnesium hydrogen phosphate, aluminum oxide, attapulgite, calcium nitrate, ammonia water and phosphoric acid; the microspheres are composed of the following components: sodium alginate Magnesium hydrogen phosphate: 13%; Aluminum oxide: 3%; Attapulgite: 24%; Calcium nitrate: 24%; The mass ratio of ammonia water and phosphoric acid is 1:4; Magnesium hydrogen and the calcium nitrate generate mineral particles of calcium hydroxyphosphate under the environment of pH=8.4; the mineral particles and the Si-O bond on the surface of the attapulgite work together to strengthen the interaction between sodium alginate and calcium ions. The network structure formed by linking to improve the strength of the hydrogel; the attapulgite, also known as palygorskite, is a water-containing magnesium-aluminosilicate clay mineral with a chain layer structure, and its internal honeycomb structure can increase ...

Embodiment 2

[0047] The microspheres of the dye-absorbing composite hydrogel are made of sodium alginate, magnesium hydrogen phosphate, aluminum oxide, attapulgite, calcium nitrate, ammonia water and phosphoric acid; the microspheres are composed of the following components: sodium alginate Magnesium hydrogen phosphate: 9%: Aluminum oxide: 3%; Attapulgite: 46%; Calcium nitrate: 14%; The mass ratio of ammonia water and phosphoric acid is 1:4; Magnesium hydrogen and the calcium nitrate generate mineral particles of calcium hydroxyphosphate under the environment of pH=8.4; the mineral particles and the Si-O bond on the surface of the attapulgite work together to strengthen the interaction between sodium alginate and calcium ions. The network structure formed by linking to improve the strength of the hydrogel; the attapulgite, also known as palygorskite, is a water-containing magnesium-aluminosilicate clay mineral with a chain layer structure, and its internal honeycomb structure can increase ...

Embodiment 3

[0056] The microspheres of the dye-absorbing composite hydrogel are made of sodium alginate, magnesium hydrogen phosphate, aluminum oxide, attapulgite, calcium nitrate, ammonia water and phosphoric acid; the microspheres are composed of the following components: sodium alginate Magnesium hydrogen phosphate: 14%: Aluminum oxide: 1%; Attapulgite: 56%; Calcium nitrate: 11%; The mass ratio of ammonia water and phosphoric acid is 1:4; Magnesium hydrogen and the calcium nitrate generate mineral particles of calcium hydroxyphosphate under the environment of pH=8.4; the mineral particles and the Si-O bond on the surface of the attapulgite work together to strengthen the interaction between sodium alginate and calcium ions. The network structure formed by linking to improve the strength of the hydrogel; the attapulgite, also known as palygorskite, is a water-containing magnesium-rich aluminum silicate clay mineral with a chain layer structure, and its internal honeycomb structure can in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com